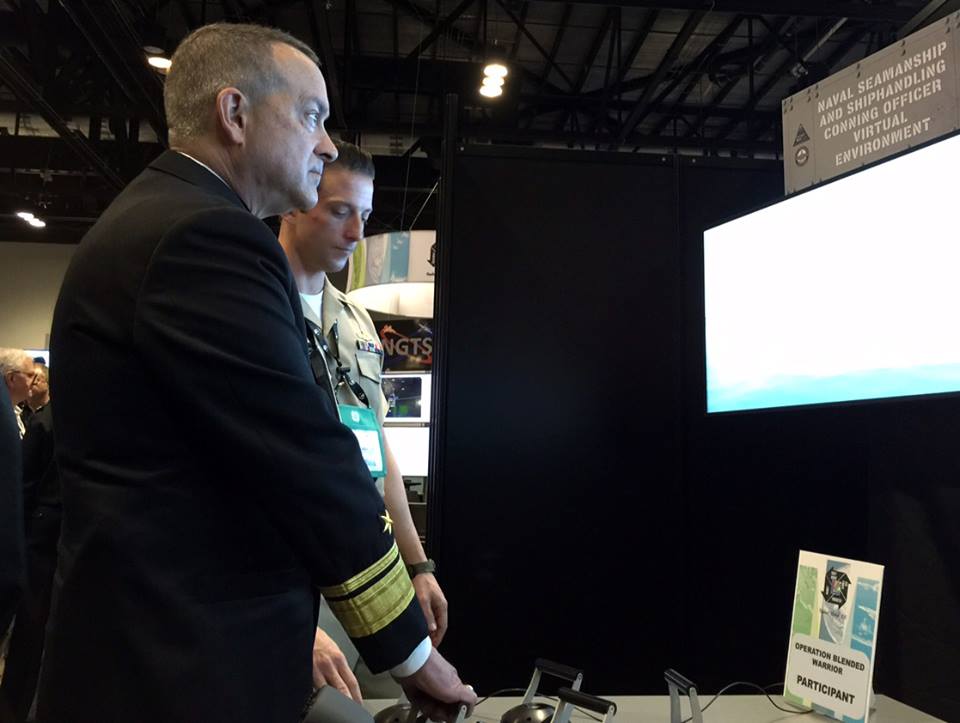

Innovation in Training and Simulation Tech: Rear Adm. Mat Winter, chief of naval research, receives a demonstration of the Naval Seamanship and Shiphandling Conning Officer Virtual Environment (NSS COVE) for littoral combat ships, at the Interservice / Industry Training, Simulation and Education Conference (I/ITSEC) in Orlando, Fl.

The Office of Naval Research (ONR) displayed a range of training technologies at this week’s Interservice/Industry Training, Simulation and Education Conference—also called I/ITSEC. New training capabilities depend on computer-enhanced or -generated virtual reality scenarios that enable warfighters to engage with computer-generated forces simulating the complexity of real environments at an affordable cost.

I/ITSEC, which ended Dec. 4, is the world’s largest modeling, simulation and training conference and was held in Orlando. High-level Navy and Marine Corps flag officers took leading roles in I/ITSEC as plenary speakers and panelists. This year’s event featured comments from the Commandant of the Marine Corps, the Chief of Naval Personnel and Chief of Naval Research Rear Adm. Mat Winter.

“Augmented Reality and Virtual Reality technologies are truly changing the way we train our Sailors and Marines,” said Winter. “ONR’s research efforts continue to lead the way in providing innovative, efficient and cost-effective training solutions for the future force.”

Some of the technology displayed by ONR included:

—Personalized Assistant for Life-Long Learning (PAL3): PAL3 is an ONR program that harnesses the power of artificially intelligent tutoring systems to diagnose what sailors need to know, and to provide needed skills when and where they need them, shipboard, pierside or in the schoolhouse. PAL3 technology aligns to the Navy’s Sailor 2025 “Ready, Relevant Learning” initiative that will reduce time to train and increase pre-deployment skills.

—Augmented Immersive Team Training (AITT): AITT uses augmented reality techniques to simulate battlefield effects like explosions enemy forces and overlay those simulations in real-world training exercises. The Marine Corps is using AITT to push realistic, scenario-based training into the field to make effective, tailored training available and affordable to deployed troops.

—Fleet Integrated Simulation Technology Testing Facility (FIST2FAC): FIST2FAC integrates multiple, stand-alone mission training systems into a single integrated whole that enables multi-platform, multi-mission training for individuals, teams, platforms and whole fleet levels. FAC/FIA C and Anti-Swarm missions were demonstrated at this year’s I/ITSEC.

“I/ITSEC provided an excellent opportunity for ONR to showcase some of its most technologically advanced simulators and training systems,” said Dr. Terry Allard, head of ONR’s Warfighter Performance Department. “Simulation-based training enables our warfighters to “train as they fight” at the operational edge that couldn’t be done with live training exercises. Integrated, networked scenario-based training will ensure our Sailors and Marines will have the skills they need to maintain warfighting superiority on the battlefield.”

I/ITSEC provided valuable opportunities to network and discover the latest technology available in simulation and training. I/ITSEC also provided a joint forum for peer-reviewed paper presentations, tutorials, special events, professional workshops, a commercial exhibit hall, a Serious Games competition (using digital game technology and approaches for training and education) and STEM events for teachers and high school students.

I/ITSEC is organized by the National Training and Simulation Association (NTSA) which promotes international and interdisciplinary cooperation within the fields of modeling and simulation, training, education, analysis, and related disciplines. NTSA is an affiliate subsidiary of the National Defense Industrial Association.

In his recent Innovation Vision statement, Secretary of the Navy Ray Mabus said, “As an institution, we have a responsibility to put innovative ideas to work solving the demanding challenges that lie ahead. We must push to develop capabilities and concepts that make us more agile and resilient.”

ONR’s presence at I/ITSEC is another example of the Navy’s commitment to innovation and delivering decisive capabilities to warfighters.

Filed Under: Virtual reality, M2M (machine to machine)