Arktos Developments Ltd. (ADL), designer and manufacturer of an amphibious vehicle known as the Arktos Craft, uses Autodesk’s simulation software to prepare its products to operate in some of the world’s most environmentally demanding locations. Originally designed as an amphibious evacuation craft for Arctic offshore oil facilities, the Arktos Craft can move from -50° C (-122° F) temperatures, through burning flames, and back again, as in the case of evacuating a burning oil rig. Additionally, the vehicle can maneuver through ice rubble fields and ice water transition zones while carrying heavy loads. They can climb steep grades, traverse over significant side slopes, and through deep mud and quicksand – making it a highly capable exploration craft for a variety of extreme conditions.

The versatile Arktos Craft has the highest proven all-around level of amphibious capability in the world. This is particularly true in the interface between ice and water.

Valmont West Cost Engineering (Valmont) provides FEA services for ADL. The firm conducts simulation for predicting vehicle performance in these severe environments. “We use Autodesk Simulation to predict critical stresses at extreme temperatures and loading conditions,” said Ioan Giosan, PhD. P.Eng at Valmont. “After finding an optimal design using FEA methods, we relied on physical testing and field use to validate the accuracy of our results.”

Vehicles can carry up to 60 people, carry heavy loads, operate in ice infested waters, and manage 34° of slope or incline.

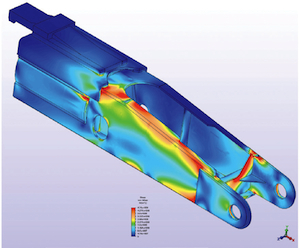

The key to the Arktos Craft’s mobility is an articulated arm between the vessel’s two main compartments. As the vehicle climbs up onto an ice shelf from the water, the hydraulics in that arm help push the front unit of the Craft up and out of the water so that the special track spikes can grab the ice.

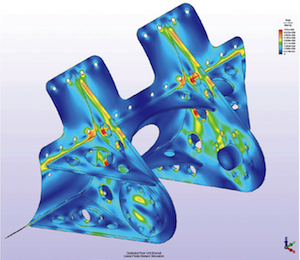

Autodesk simulation software allows engineers to design new attachments for the craft and simulate how those modifications will affect performance.

Using the software’s multi-physics capabilities, Valmont was able to show ADL engineers how thermal stress caused by temperature extremes would combine with mechanical stress within the articulated arm between the units. Additionally, since the arm would experience repeated compressive and tensile loading. Valmont also analyzed fatigue life using the simulation tools.

Engineers at Valmont use the simulation software to study a bracket on the main body.

Autodesk, Inc.

www.autodesk.com

Arktos Developments Ltd.

www.arktoscraft.com

Valmont West Coast Engineering

www.valmont.com

Filed Under: Software • FEA, Software • simulation, ENGINEERING SOFTWARE, Off highway • construction • agriculture

Tell Us What You Think!