A physical layer for Industrial Ethernet, Single-Pair Ethernet combines high data rates with a lightweight cable design, streamlining communication across automation levels.

By Sagar Patel, Product Manager at Lapp North America

With the rise of the Industrial Internet of Things (IIoT), the goal for many manufacturers is to connect all the machines, controls, actuators, and sensors in their plant. That’s easier said than done, however. In reality, there are many system inconsistencies at play, making communication between the field device, control and enterprise levels anything but easy.

To reap the benefits of the IIoT, manufacturers need smooth, seamless communication across all automation levels. Although Ethernet has long been the communication standard at the control level, bus systems still dominate the field level, limiting potential data flow. The solution is to implement cost-effective and space-saving infrastructure, enabling non-Ethernet field devices to communicate with the Ethernet networks above it.

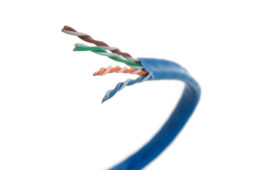

Single Pair Ethernet (SPE) has emerged as this critical bridge, making the field level smarter while ensuring consistent, reliable network communication across the entire automation pyramid. SPE is a cable design that uses a single pair of twisted copper wires to transmit data at speeds up to 1 gigabyte per second (Gbps), allowing real-time, continuous data transfer to and from the field level. It offers additional advantages including supporting cable lengths up to 1,000 meters (at 10 Mbps), minimizing space requirements and easing installation.

The following white paper takes a deep dive into this game-changing cable construction, including its features, benefits and standardization practices, empowering you to quickly and effectively use IIoT communication technology to improve your manufacturing facility.

The limits of traditional network technologies

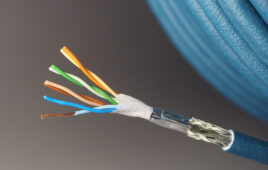

Until now, manufacturers have typically relied on bus networks to enable the flow of data from field devices. One of the most widespread bus communication methods for automation technology is PROFIBUS, a serial fieldbus technology established over 30 years ago that uses one pair of cores in a BUS cable. Later, as the industry expanded from buses to Industrial Ethernet, particularly at the control and enterprise levels, PROFIBUS and PROFINET International (PI) developed PROFINET. This Industrial Ethernet protocol uses two pairs of cores to transmit Ethernet at a rate of 100 megabits per second (Mbps). Some manufacturing operations even use Gigabit (GB) Ethernet, a transmission technology that requires four pairs of cores and provides data rates up to 1 billion bits per second, or 1 GB.

With the rise of the connected factory, bus systems can no longer handle the large data transmission rates required by the ever-increasing number of sensors in production facilities. Despite the benefits of Industrial Ethernet solutions, Ethernet is not always suitable for connecting devices at the lowest field level. Cat.5 and Cat.7 cables can be too large to efficiently connect hundreds, possibly thousands, of individual sensors spread throughout production environments.

Another challenge is connection complexity. In order to bridge the communication gap between the field device level (bus) and everything above it (Ethernet), manufacturers must install translators and gateways. In addition to driving up system costs and complexity, the field work required to install this additional hardware increases the risk of installation errors.

No more isolated networks: SPE to the rescue

A streamlined cable solution, SPE simplifies Ethernet connectivity from the sensors, up through the control and company levels, and then to the cloud — opening new application areas for Industrial Ethernet. A lightweight, efficient cable design, SPE reduces the number of cores to two, enabling 1-Gb Ethernet communication over a single pair of cores. It also eliminates the need for costly gateways between Ethernet and bus networks, reducing installation work and minimizing the chance of errors. Because the cabling itself requires less space, SPE significantly reduces component costs.

In addition to high data-transmission speeds via Ethernet, SPE can supply power to end devices via Power over Ethernet (PoE), a standard that specifies the power distribution method for use over a single twisted-pair link. PoE can provide 0.5 to 50 W of power over a twisted pair to power devices like cameras, sensors, and remote input/output (I/O), and it further reduces costs by eliminating the need for additional cabling to power devices.

Benefits of SPE include the following:

- SPE supports data rates up to 1 Gbps.

- Cables can be deployed up to 1,000 m.

- SPE is more secure with end-to-end protection down to the edge.

- It is an open communication tool — no dependence on one manufacturer or software.

- SPE is a cleaner network topology, eliminating the need for costly, complex gateways.

- The cables feature a small form factor.

- SPE offers a hybrid solution for data and power.

SPE application areas

By enabling continuous, long-length communication between the sensor level and cloud, as well as providing power supply via PoDL, SPE offers powerful applications in many industries.

Process automation. SPE can bridge long distances in large chemical plants, where analog cables or bus networks — some with data transmission rates of just 31.25 kilobits (kbit) — are still the norm. The Ethernet Advanced Physical Layer (Ethernet-APL), an offshoot of the IEEE 802.3cg (10BASE-T1L) standard, defines additional properties for these applications, taking into account the use of SPE cabling in explosive areas.

Transportation. SPE shines in electric transportation (e-transportation) applications because of its small, lightweight form factor, reducing weight and bend radii by up to 55 and 30%, respectively. Compared to a cable with four wire pairs, which weighs around 4.6 kilograms (kg) per 100 m, an SPE cable weighs only 3.0 kg. Specific use cases in the transportation sector include passenger information systems, seat reservation systems, passenger counting visual (PCV) systems and closed-circuit television (CCTV).

Building automation. SPE can be used to network sensors in fire alarm systems, light or temperature sensors, access control systems, information boards and much more.

SPE standardization

SPE is covered by several international standards, including the Institute of Electrical and Electronics Engineers (IEEE). In addition to specifying the primary transmission method, IEEE 802.3 stipulates the transmission channel, transmission length and number of connectors. Other relevant standards organizations include the International Organization for Standardization (ISO), the International Electrotechnical Commission (IEC) and the Telecommunications Industry Association (TIA), all of which cooperate with IEEE 802.3.

When it comes to the cabling, several IEC 61156 standards are in progress, including IEC 61156-11 and IEC 61156-12 for 600-megahertz (MHz) data cables in permanent and flexible installations, respectively. Others include IEC 61156-13 and IEC 61156-14 for 20-MHz data cables in permanent and flexible installations, respectively.

Regarding the SPE connectors, several IEC 63171 standards are under development. The first and only standard for connections in industrial applications that has been adopted by all major standards bodies is IEC 63171-6, which covers all versions from IP20 to IP 65/67. Published in 2020, IEC 63171-6 describes the T1 Industrial Style SPE plug-in face.

This T1 industrial connector has a very robust design, including stainless steel shield plates, and a rugged core and cable gland. The interface also features a strong, stainless steel lock to maintain a secure connection — even in harsh production environments — and a stainless steel jacket that encloses the entire connector, minimizing electromagnetic interference (EMI).

LAPP USA

lappusa.com

Driving SPE forward

The SPE Industrial Partner Network, of which LAPP is a member, consists of many electrical connection companies, including cable and connector manufacturers, as well as companies that specialize in advanced Single Pair Ethernet technology. The group expects SPE to replace the current fieldbus systems at the sensor and actuator level, providing the core infrastructure for intelligent sensors and actuators in modern smart factories. The goal of this partnership is to continue to create standardized interfaces and system components, all while working closely with various international committees.

SPE benefits at a glance

- Enables Networking with Transmission Control Protocol/Internet Protocol (TCP/IP) without system disruptions. IP can address all field participants.

- Suitable for real-time critical applications thanks to time-sensitive networking (TSN).

- Accommodates distances up to 1,000 m, enabling more flexibility in cabling and requiring fewer switches.

- Can supply power to terminal devices via the same cable using PoDL.

- Sustainable, thanks to an elimination of batteries compared to wireless systems.

- Uses less material, lower weight over traditional 2- and 4-pair Ethernet.

- Offers flexibility and space savings in drag chain applications, conduits, etc.

- Reduces installation errors and saves assembly time.

- Improves operational reliability.

LAPP cables and SPE

LAPP has contributed to SPE cable development with the introduction of our ETHERLINE T1 product family, consisting of SPE cables for use in industrial machinery and plants:

- ETHERLINE T1 FD P is a shielded 26AWG cable for use in cable chains.

- ETHERLINE T1 FLEX is an 22AWG cable for occasional movement.

- ETHERLINE T1 P FLEX is an 18AWG cable suitable for distances up to 1,000 m.

Filed Under: Wire & Cable Tips