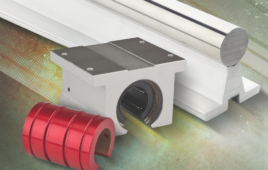

Specialty coatings for SKF® rolling bearings offer solutions to resist wear or to insulate against stray electric currents. Most bearing types can be coated to promote longer bearing life and increased machinery uptime.

Promoting wear resistance, a patented NoWear® coating applied on contact surfaces can withstand severe operating conditions due to sudden load and speed variations, poor lubrication conditions from high temperature or low lubricant vicosities, vibration, smearing, and/or solid particle contamination. The coated bearings prove harder, exhibit less friction (and resulting heat), and can better tolerate potential damage from contamination and/or marginal lubrication. Applications include compressors, pumps, fans and blowers, and gearboxes, among others.

Offering insulating properties, INSOCOAT® rolling bearings protect against potential damage caused by the passage of AC or DC electric current. Applications include variable speed motors, generators, and associated motor-driven equipment. Their thin aluminum oxide layer integrates the electrical insulating function into the bearing to form a superior barrier against electric arcing and potentially damaging bearing erosion. Coatings selected based on required resistance may be applied to either bearing bores or outside diameters, depending on bearing size.

All coated bearing boundary dimensions conform to ISO and ABMA standards and can easily replace non-insulated bearings without requiring design changes or rework prior to normal mounting. Coated bearings are suitable for all types of shafts or housings and can be further customized to satisfy particular application requirements.

: Design World :

Filed Under: Bearings

Tell Us What You Think!