by Laura Carrabine, Senior Editor

Traditional motion controllers mainly rely on complex centralized motion control architectures to handle the high-dynamics of multiple-input multiple-output (MIMO) cross-coupled feedback topology of gantry systems. In addition, traditional units require expert installers for proper operation and maintenance.

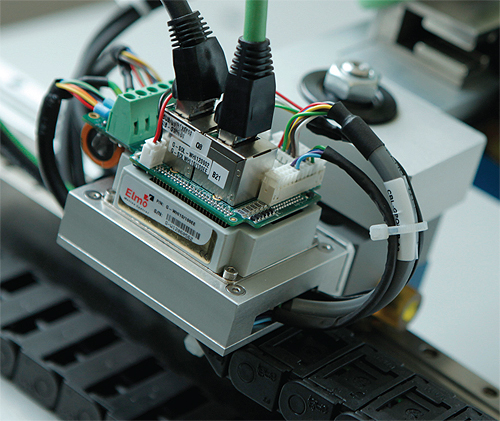

The drives are small so they can be mounted next to a motor. There is no need for specialized, rugged moving cables which can be problematic at times.

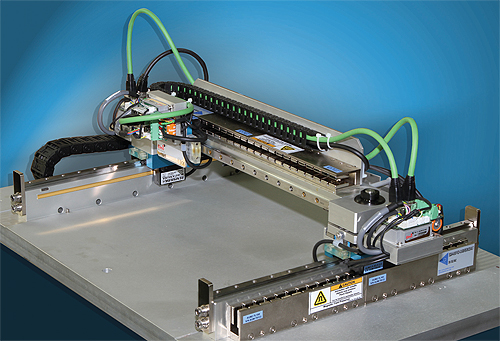

A new product family proposes a more efficient servo control approach for high precision gantry systems based on fully distributed motion control architecture. This approach is suitable for standard dual axes gantries and can be extended to full 4-axis planar control with minimal effort. The upper gantry bridge is carried by two identical symmetric axes. Due to the mechanical and feedback coupling of the x1 and x2 gantry axes, a MIMO high order dynamic transfer function system is composed that is handled by a MIMO control law.

Each of the carrying axes has its own mechanical bearings and tracks, feedback, motor, and a dedicated power servo system driving it. The MIMO control law operates on the single axes x1 and x2 position feedback inputs where the following normalized system positions are defined:

Gantry center position:

X = x1+x2/2

Gantry yaw position:

Θ = x1-x2

The control target is to follow a user-defined reference on the main gantry center position, while keeping the yaw error: Θ = 0 . Here, the MIMO control system output has to generate two currents commands — one for each axis drive.

The main challenges are a combination of the following:

- Synchronizing the servo sampling of both channels (due to the MIMO control loop structure, jitter on sampling of different channels is unacceptable).

- Synchronizing the servo loop outputs and PWM signals.

- Executing the MIMO control law, this can include nonlinear algorithms.

- Transferring the feedback data from the slave axis x2 to the master x1 and control law output vice versa.

Distributed gantry control eliminates excessive field bus network loads by implementing a high speed serial communication channel between the gantry servo drives. One axis is logically defined as a gantry master. It retrieves all the required information from the slave, computes all MIMO control laws, and keeps the system fully synchronized to the drive pulse width modulation (PWM) level.

The upper gantry bridge is carried by two identical symmetric axes. Due to the mechanical feedback coupling of the x1 and x2 gantry axes, a MIMO high order dynamic transfer function system is composed that is most effectively handled by a MOMO control law.

The external reference can be any drive interface such as:

- Field bus commands (EtherCAT or CANOpen)

- Pulse and direction commands

- Direct ethernet connection from a host PC

- Analog ±10 V commands

- Internal drive user program

Elmo Motion Control Inc.

www.elmomc.com

Filed Under: Drives (servo) + amplifiers, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!