Manufacturing industries around the world are being transformed by recent step changes in digital connectivity, advanced machine analytics, high performance computing, interlinked cyber-physical systems, sophisticated new materials, and new manufacturing capabilities. Design technologies must incorporate these advancements to fully harness the product complexity enabled by the fusion of computing science, modern materials, and manufacturing technology. Otherwise we will be left with, for example, hybrid manufacturing technologies that allow seamless combinations of additive and subtractive processes, but very few designs that take advantage of (and are enabled by) these capabilities. Efficiently and effectively harnessing the enormous design space complexity introduced by the non-linear transformations in materials and manufacturing technology is key to product design innovation.

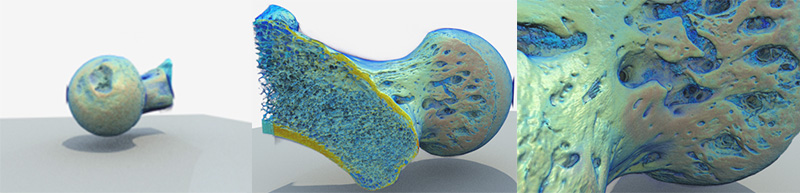

At the very least, we must be able to represent on a computer what we can fabricate, for example a detailed representation of a human bone obtained from high resolution CT scan for prosthetic synthesis using additive manufacturing, or lightweight composite and graded materials distributed over highly detailed (ir)regular aircraft structures at multiple length scales. To then innovatively design (or re-design) such parts and assemblies, product designers must make critical tradeoffs in the preliminary stages of the design process. But it is humanly impossible to think through the combinatorics of such material and structural complexity, and therefore design software must include artificial intelligence as a problem-solving team mate. We believe that coupling 3D representations of highly complex structures with AI, model-based reasoning, and data-driven decision-making is a fundamental innovation required to realize the next generation of design software systems.

Standard computer aided design and computer aided manufacturing (CAD/CAM) software and product lifecycle management (PLM) systems are still quite useful for describing traditional design geometries and materials. But when manufacturers rely on aging legacy tools and materials, they may be forced to think too narrowly about their designs (especially given the design freedom available today), limiting their ability to innovate. Software tools that cannot scale up to meet escalating levels of complexity in hardware, systems, and process complexity will end up constraining manufacturers to outmoded models. In the future, design representations will be hybrid, fusing complex geometric information with material physics, design optimization, planning/search, and machine learning. Such an approach to design will compel and catalyze innovation in an extensive range of products, from ordinary auto parts to aerospace engines. As a 2017 McKinsey report clearly lays out, the additive manufacturing technologies already in use are conveying significant benefits as well as long term advantages to the manufacturers adopting them for design, engineering, manufacturing, and service processes. Imagine what we could do if our ability to design products really pushed the limits of fabrication technology.

Bridging the Design Gap

Harnessing the tidal wave of new materials and fabrication methods to enable designs that are unimaginable today requires a concerted effort that is beyond the scope of any single designer or manufacturer. To that end, researchers at Palo Alto Research Center (PARC), a Xerox company, are working with a group headed by the Defense Advanced Research Projects Agency (DARPA) to rethink the foundations of CAD/CAM/CAE technologies. The goal is to enable product designers to create novel designs that exploit the geometric and material complexity made possible by additive and hybrid manufacturing. DARPA’s TRAnsformative DESign (TRADES) research program is developing technologies to facilitate the creation of complex multi-material objects that optimize multiple design objectives and stress the limits of fabrication technologies.

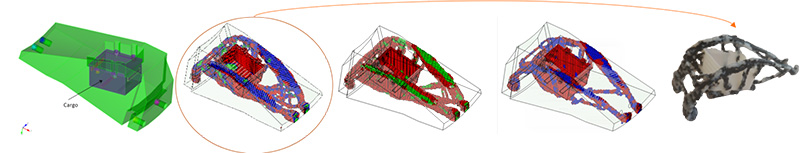

The aim of the platform PARC is building under the TRADES program is to streamline the production process, from initial mock-ups to final parts production. It is pre-programmed to work with a range of materials and composites, with specific tools for additive and hybrid manufacturing. The programs can automatically optimize shape and material layout, along with some design parameters for an object, and determine the best settings for fabrication. This breakthrough approach is critical to the intelligent manufacture of objects with billions of geometric attributes, such as jet engines or gas turbines. Examples of PARC’s innovative approach to multi-material design optimization and high resolution multi-length scale representations are shown in Figures 1 and 2.

Figure 1: A bracket carrying sensitive cargo is redesigned with multiple materials. Three possible designs are shown where the mass of the original bracket is reduced by 95% while retaining critical features by using a non-trivial material distribution. Each color represents a distinct material type. The three-material design is fabricated on the far right.

Figure 2: Femur bone representation, cutaway view, and closeup. No other design software can represent designs with multiple materials at this resolution without requiring many GBs if not TBs per model. Applications for the medical, aerospace and automotive industries are enabled by this representation.

Hybrid Future: Advanced Manufacturing Models, Materials and Processes

As we envision it, the future of manufacturing will be AI-enabled with hybrid design representations, hybrid processes and hybrid materials. Hybrid manufacturing approaches will combine subtractive and additive manufacturing techniques by incorporating the widespread use of 3D printing and design tools.

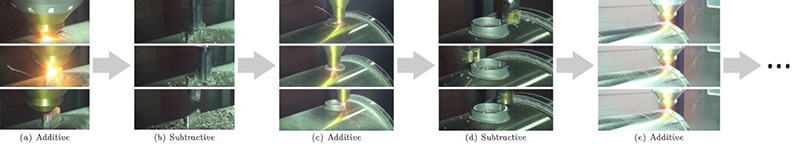

To dramatically increase efficiency, we should leverage the best aspects of additive and subtractive manufacturing — each approach offers certain advantages and disadvantages. For example, a hybrid planner can additively manufacture new product features. While printing the design, some support structures may be required to facilitate the process. Later, the AI engine can automatically direct the system to subtract those support structures without introducing too much complexity. In other words, an AI planner can ask an additive process to deliberately add excess material knowing that a future subtractive process will remove this material, a novel approach that may be key to making the design feasible. Going further, the AI engine can automatically construct interleaved additive and subtractive processes (such as shown in Figure 3) for machines that integrate both technologies.

Figure 3 :Interleaved additive and subtractive manufacturing operations on the Mazak Integrex i-400AM

We have similar expectations for the adoption of hybrid materials. For instance, to create a composite layer of materials using current systems, each layer must be designed separately and then stitched together. Such complexity requires extensive design and manufacturing planning that drives up costs; PLM software cannot accommodate it. By contrast, 3D printing systems are now moving towards the ability to fabricate smoothly gradient material properties, from hard to soft materials.

Figure 4 shows an example of a graded material which allows for continuous transition of material properties throughout the part. PARC’s digital graded material fabrication technology is revolutionary because it enables voxel-level control over material composition, enabling the production and optimization of digital gradients in complex objects.

Manufacturers are beginning to leverage the extreme computational power accessible today via cloud computing, GPUs and ever faster CPUs in advanced design, modeling, and production. For instance, using the representation and rendering technology we developed for DARPA, material scientists can now render a high-resolution CAT scan of a patient’s femur bone (Figure 2) for interactive design. 3D printers can then replicate the resolution of that specific bone structure to manufacture it accurately. PARC is diligently working to develop the capabilities required to represent and design with hybrid materials at such a precise level of detail; again, PLM software is not up to the task.

How Do We Design the Future?

Adopting AI planning tools and model-based reasoning systems will inspire a wave of fresh thinking. No legacy computer-aided design system today can automatically determine how to set up a tools platform and connect that geometry to model-based AI and planning. Future manufacturing systems will take in diverse 3D geometries to suggest extensive options for the creation of cost-effective designs with existing tools.

In order to enable advanced manufacturing success, we are working to enhance the engineer’s expertise by having our tools represent, plan, and manage complex, graded geometries and multiple length scales for materials. Doing this effectively will require incorporating material and manufacturing uncertainty into the physics analysis of all functional parts.

Companies (and countries) all over the world are gearing up for a bold new era of manufacturing. As products, processes, and materials become more complex, design and manufacturing decisions need to addressed earlier in the product lifecycle and supported by smarter systems. With more options to choose from at every step, each manufacturing decision becomes more complex and has a greater impact on cost, efficiency, and quality. As advances in AI and material physics converge, we’ll be able to build more visibility and innovation into every stage of the product design, with results hopefully more thrilling than science fiction.

Filed Under: 3D printing • additive • stereolithography, Flanges • supports • mounts • brackets, Product design