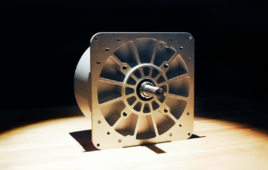

These stainless steel motors meet the extreme environment needs of the food and beverage industry. Food Safe motors have smooth contours and sealing that exceeds IP69K for water to maximize motor life in high pressure, sanitary cleaning environments.

The high ingress protection rated enclosures offer fully encapsulated windings, sealing the motor inside and out. Combined with a laser marked nameplate and a footless mounting design, crevices are kept to a minimum and allow the motor to withstand clean-in-place procedures.

Worker safety is another important component in the food safe stainless steel motor design. A 3 piece-rotatable conduit box gives workers easier access to route incoming power supply. Color-coded leads also help to quickly, and correctly tie the motor into the electrical system, using the waterproof heat shrink connectors. On larger frame sizes, lift lugs are fully welded to the frame to easily set the motor in place before attaching to the driven equipment.

The platform spans single and three phase ratings. Three phase ratings meet NEMA Premium efficiency levels and are available in totally enclosed, non-vented enclosures in the power range of 1/2 – 3 hp. Totally enclosed, fan cooled designs are available in power range of 1/2 – 15 hp. They are available in 2, 4 & 6 pole versions for 230/460V at 60 Hz.

Baldor Electric Co.

www.baldor.com

Filed Under: Food + beverage, Motors • ac

Tell Us What You Think!