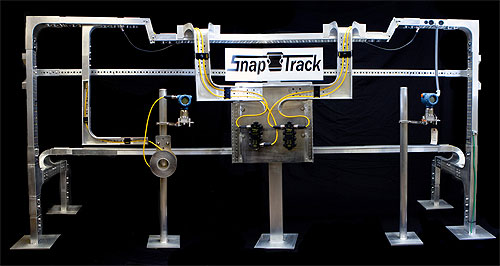

Minneapolis, MN – TechLine Manufacturing has introduced a stronger, more efficient cable tray system for electrical contractors that–in conjunction with the use of TURCK instrumentation tray cable (ITC), cordsets and quick disconnect junction boxes–lessens labor on the plant floor during electrical installation of instrumentation and control equipment. TechLine’s UL certified Snap Track aluminum cable tray system, assembled with patented push pins in place of traditional nuts and bolts, simply snaps into place without the use of tools, thus reducing installation time. Snap Track cable tray systems are designed to accommodate the limited width requirements of instrumentation cable and have a high load bearing capacity.

Snap Track Cable Tray with TURCK Quick Disconnect Technology

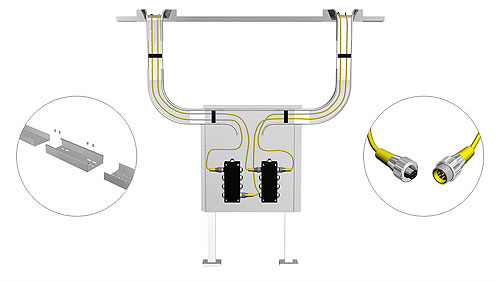

TURCK has an extensive line of ITC rated quick disconnect cable for use in place of rigid metal conduit to eliminate the need for boundary seals in some hazardous locations, reducing installation time, commissioning and maintenance.

Graphic Rendering of Snap Track Cable Tray with TURCK Quick Disconnect Technology

Snap Track systems include solid side rails with inward “C” configuration to provide superior strength and cable protection–from the control room to the instrument and all points in between, including drops, brick panels and service loop attachments at the instrument stand. TURCK’s IP and NEMA rated junction bricks equipped with quick disconnect technology easily mount to TechLine’s panels. The complete line includes 7/8 16UN and M12 standard, miniature, low-profile, terminal chamber and NAMUR junction bricks with integral cables or home run connectors. They are available for virtually all industrial networks, as well as HART and analog wiring.

TURCK

www.turck.us

::Design World::

Filed Under: Cables + cable management, CONNECTIVITY • fieldbuses • networks, Connectors (electrical) • crimp technologies, ELECTRONICS • ELECTRICAL

Tell Us What You Think!