Residents hold signs during a hearing over a gas leak at the Southern California Gas Company’s Aliso Canyon Storage Facility near Porter Ranch, in Los Angeles. (AP Photo/Richard Vogel)

The Southern California Gas Company has been ordered to permanently shut down its well that’s been spewing natural gas in the Los Angeles area since October.

Seven failed attempts to plug the leak have weakened the well and increased the chance of a potential blowout, the Los Angeles Times reports.

The South Coast Air Quality Management District’s hearing board issued the closure order on Saturday, as well as outlined several other requirements, including immediate orders to minimize leaking gas, monitor the leaking well with infrared cameras and develop an “enhanced” detection and reporting program.

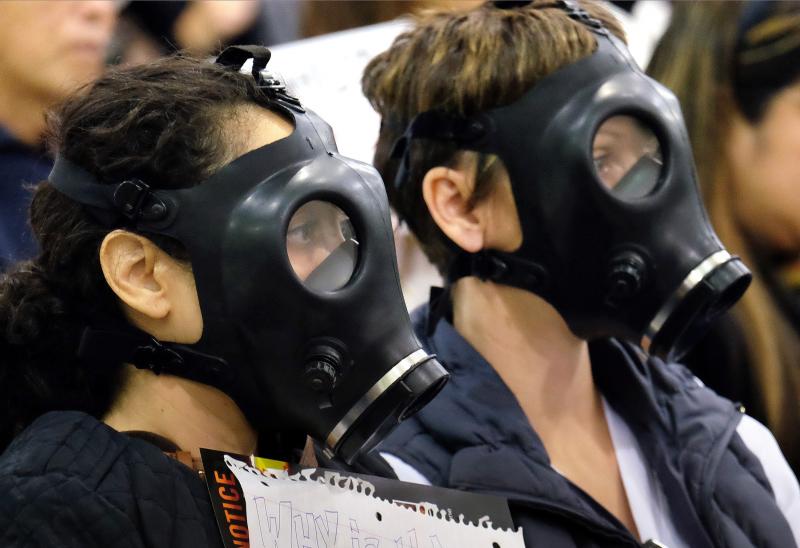

Protestors wearing gas masks attend a hearing over a gas leak at the southern California Gas Company’s Aliso Canyon Storage Facility near the Porter Ranch section of Los Angeles. (AP Photo/Richard Vogel, File)

While SoCalGas works to plug the leak by drilling a relief well — which is expected to take until late February — the company must fund an independent study to monitor the health of the nearby Porter Ranch neighborhood’s residents.

“[The order] will require the utility to thoroughly inspect all other wells at its Aliso Canyon storage facility to help prevent another major leak in the future,” said Barry Wallerstein, the group’s executive officer.

The leak — which has so far cost SoCalGas upward of $50 million — is blamed for numerous reports of nosebleeds, headaches and nausea in the area. Air quality tests even found a known carcinogen (benzene) at double its normal level.

Levels of methane, a potent greenhouse gas, were up to 50 parts per million in area, the Los Angeles Times reported. “This is probably 20 times bigger than anything else we’ve measured,” said Stephen Conley, pilot of the pollution-detecting airplane and scientist at the University of California, Davis.

The Associated Press reports that 3,000 families have been displaced so far, paid for by SoCalGas, and as many as 3,000 more might still be forced to relocate.

The hearing board will review SoCalGas’ progress on Feb. 20, but currently, the order extends through Jan. 31, 2017.

Do you think SoCalGas is doing enough to mitigate the leak’s damages? Comment below or tweet me@MNetKatie.

Filed Under: Industry regulations