Kliklok-Woodman is a leading designer of food-packaging equipment and has customers in the bakery, snack food, confectionery, and frozen and prepared food industries. The company developed a packaging machine called the CELOX Endloader Cartoner. It sits at the end of a production line and fills cartons with packaged foods and then seals them.

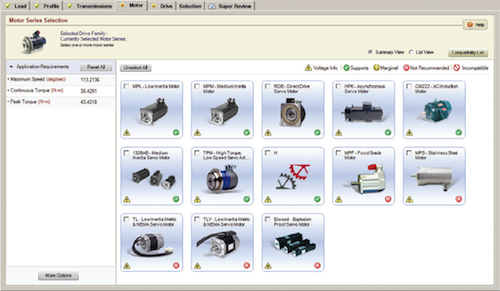

Motion Analyzer is a digital modeling and simulation tool that helps size and select optimal motion systems – ones that use the appropriate amount of energy and achieves the specified speed and throughput.

Each machine has a flap-kicker, a finger-like device that deflects the flaps of each carton outward to ensure the product is smoothly loaded into the carton. The original flap-kicker was powered by a pneumatic cylinder, which meant that it would wear down at a quicker pace than a servo-driven mechanism when used at high speeds.

So when a customer requested a CELOX with a flap-kicker to operate reliably at speeds up to 325 cartons/min, Kliklok-Woodman engineers went to work designing a servo-driven flap-kicker. They used Allen-Bradley Motion Analyzer software from Rockwell Automation. Motion Analyzer is a digital modeling and simulation tool that helps size and select an optimal motion system – one that uses the appropriate amount of energy and achieves the specified speed and throughput. The software also reduces the time required to design, develop, and deliver a new machine.

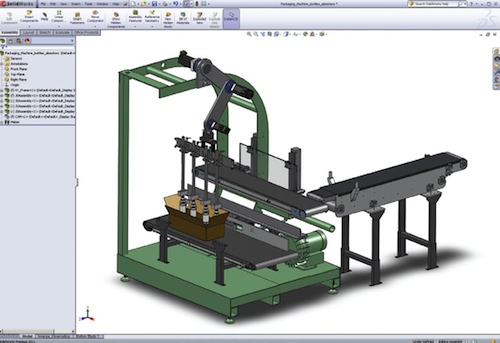

The design engineers use SolidWorks 3D CAD software to create mechanical designs. Rockwell Animation and Dassault Systemes formed a strategic partnership to link their mechanical, controls, and electrical design software packages. SolidWorks integrates with Motion Analyzer through API calls which provide a live link between the two packages.

SolidWorks is integrated with Motion Analyzer to help machine designers digitally prototype a machine.

The design team created motion profiles of the servo-driven flap-kicker in Motion Analyzer, and then transferred the profiles to SolidWorks to visualize how the machine moved. SolidWorks calculated the torque required to move the load through its profile, which Motion Analyzer used to size and select motors and drives. The integration between the two software products helped the designers choose an optimal solution for the specific application.

By digitally modeling and prototyping machine designs, mechanical, electrical, and control engineers collaborated earlier in the design phase. In this case, Kliklok-Woodman shortened the design phase of the new CELOX machine by combining electrical and mechanical design into one step. Motion Analyzer helped the mechanical engineers size the motor and gearbox simultaneously.

Kliklok-Woodman estimated it cut design time by one-third compared to using manual calculations and trial-and-error methods for finding the right motor size. Using Motion Analyzer also eliminated the material costs the company would have incurred if it had built a new flap kicker to test different motor sizes.

The CELOX Endloader Cartoner uses advanced motion controls for fast product changeovers.

In addition Kliklok-Woodman engineers chose an Allen-Bradley B310-MP-Series Food Grate (MPF) servo motor to meet the food manufacturer’s high-performance demands in a small space. The motor can withstand high-pressure, caustic wash-downs, and is more reliable than the pneumatic cylinder.

The CELOX integrates the MPF servo motor with other solutions to deliver motions precision, accuracy, and reliability. These include Allen-Bradley Kinex 6000 multi-axis servo drives to allow easy speed and position adjustments and fast product changeovers. An Allen-Bradley PanelView Plus 1000 touch-screen operator interface allows employees to monitor machine activity including status and diagnostics.

Kliklok-Woodman

www.kliklok.com

Rockwell Automation

www.ab.rockwellautomation.com

::Design World::

Filed Under: Software • 3D CAD, ENGINEERING SOFTWARE, Packaging

Tell Us What You Think!