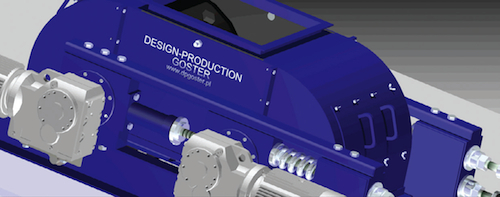

Goster is a Polish design and contracting company whose main business is manufacturing state-of-the-art mining machinery. Its engineers use Solid Edge software because the tool can handle innovative designs and modifications that are required during every stage of product development. Using the software, Goster also developed designs and related documentation faster than its traditional 2D processes.

Using Solid Edge software helps Goster focus on mining machinery market and win new business.

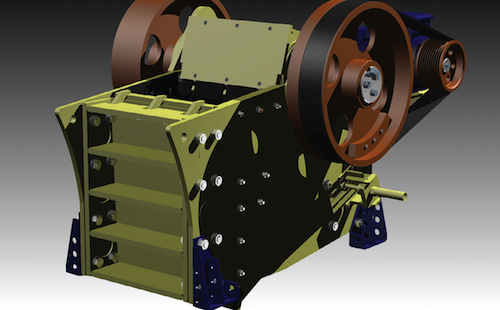

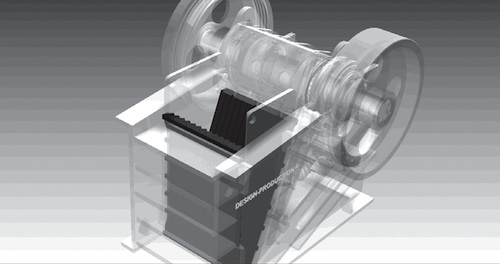

“The unique characteristics of our industry require us to take an individual approach to every customer project,” said Anna Pater, Goster’s owner. “In the beginning of each process, customers provide us with their expectations and assumptions. We can quickly showcase customer requirements and key project assumptions. During the customer consultation phase, we can demonstrate how products will look and operate by showing them 3D models. Using Solid Edge also makes it easy to develop documentation in two to three weeks for assemblies with as many as one thousand parts.”

Deploying Solid Edge has contributed to increasing Goster’s engineers’ productivity and shortened product design lead time.

The use of Solid Edge helped Goster achieve its main business goal of focusing on services for mining enterprises. The use of the software has also helped Goster avoid the high costs of manufacturing new device prototypes. Instead, Goster shows customers digital designs to demonstrate how products will look and perform.

Preliminary designs based on customer requirements can now be developed in two or three days.

“We wanted to leverage our expertise to design a completely new line of modern machines and show them with maximum fidelity. These designs are used to show future customers visualizations of products, instead of building physical prototypes, which is an extremely costly process,” noted Pater.

Siemens

www.siemens.com/plm

::Design World::

Filed Under: Factory automation, Software • 3D CAD, Digital manufacturing, ENGINEERING SOFTWARE

Tell Us What You Think!