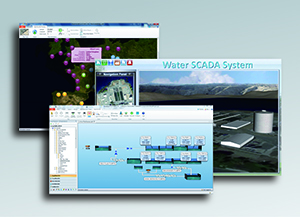

Mitsubishi Electric Automation recently released MC Works64, a PC-based supervisory control and data acquisition software suite that improves the visibility of manufacturing operations. Graphical user interfaces, alarm and event management, and data logging and trending are core features supported by the MC Works64.

Other key features of MC Works64 include:

Other key features of MC Works64 include:

- vector-based 2D and 3D graphics to contextualize data

- visibility for geographically dispersed assets

- grid visualization of large data sets

- advanced application event scheduling

- centralized configuration and runtime interface

- OPC-UA connectivity offering universal connectivity to data

MC AppBuilder, a component of MC Works64, combines database technology with a user-friendly web interface to associate graphic symbols, faceplates, control programs and various types of communication interfaces into a single location. Aggregating this data into a common database automatically generates monitoring screens, PLC programs and OPC communication settings. MC AppBuilder is expected to substantially reduce engineering and system setup costs for system integrators. And with MC Works64, executives can enjoy real-time data exchange with the factory floor from their mobile devices, while plant managers will be able to minimize downtime, reduce operating cost and improve operational efficiency.

“MC Works64 is an advanced HMI/SCADA solution, but unlike other similar offerings, it is extremely easy to use,” said Agnieszka Zupancic, solution marketing, Mitsubishi Electric Automation. “The user-friendly interface allows developers to get their HMI/SCADA system up and running in a minimal amount of time. Whether the user will monitor and control industrial and manufacturing processes at a single site or on a global scale, MC Works64 is a great solution.”

Mitsubishi Electric Automation

us.mitsubishielectric.com

Filed Under: Data acquisition + DAQ modules, ENGINEERING SOFTWARE

Tell Us What You Think!