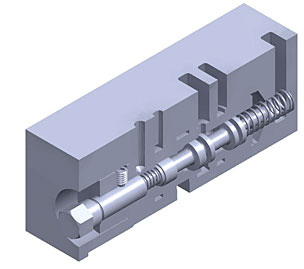

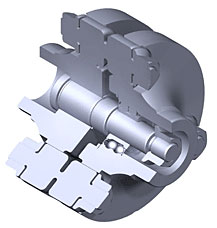

Aftermarket auto transmission component-maker Sonnax uses SolidWorks 3D CAD software to re-engineer worn out parts so they are as good or better than the original. Using SolidWorks, Sonnax engineers have become more productive and more creative in their design approaches than with 2D software.

Since 1978, Vermont-based Sonnax has been designing, manufacturing, and distributing replacement components for automatic transmissions, torque converters, drive shafts and related products worldwide for the passenger vehicle, racing and heavy-duty vehicle markets. Precision and durability are critical as its parts are used in rebuilt transmissions that often carry 100,000 mile warranties.

‚“We get worn-out parts that we reverse

engineer to find out where the part failed,‚†said Steve McAllister, an

engineering manager at Sonnax. ‚“SolidWorks lets us identify the

original failure point and design it right out of the product.‚â€

Sonnax prepares models of auto transmission components with SolidWorks 3D CAD while designing more durable components with longer service lives.

Sonnax engineers need to study every design aspect of a city bus drive shaft, for example, to make sure that the replacement part will last. Because the bus travels hundreds of miles every week, durability is critical. Sonnax engineers have to collaborate closely with part suppliers since many aftermarket parts are custom designed to a specific vehicle. ‚“There‚’s a lot of back and forth in the design stage to meet customer demand,‚†said McAllister. ‚“SolidWorks substantially cut the time for modifying the designs based on supplier feedback from when we had to change multiple (…2D) drawings. That helps us deliver products faster.‚â€

Sonnax also uses SolidWorks eDrawings email-enabled communication tool to share 3D models and 2D drawings of its components with suppliers and customers. They also use PhotoWorks photorealistic rendering tool to create life-like images of its parts for the technical documentation that accompanies the parts ‚– a process that previously was delayed up to three weeks while engineers had to wait for the prototype to photograph it. Now the documentation is ready before the part arrives. Sonnax also uses SolidWorks Simulation and Flow Simulation software to analyze component durability and fluid flow to ensure optimal performance.

Dassault SystƒÂ¨mes

SolidWorks Corp.,

www.solidworks.com

::Design World::

Filed Under: Software • 3D CAD, Automotive, ENGINEERING SOFTWARE

Tell Us What You Think!