Edited by Mike Santora

Optoacoustic tomography (OAT) is a technique for generating high-resolution images of biological tissue that scatters light waves, typically biological tissue.

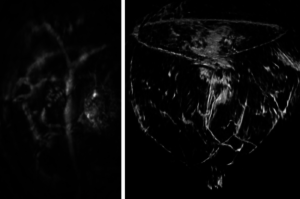

Volumetric image of the breast taken from clinical breast imaging system

Left: Section of the breast image showing a tumor and the vasculature being recruited by the tumor.

OAT systems create these images with pulses of dark red light that have a maximum duration of 50 nanoseconds. These pulses heat the tissue and cause it to expand launching ultrasound wave, a phenomenon known scientifically as an optoacoustic effect. This thermo-elastic expansion produces high-frequency acoustic or ultrasonic waves that the imaging scanner detects and uses to create an image with computational methods such as filtered back-projection. OAT is unaffected by the scattering of photons, allowing it to take high-resolution images of deep biological tissue.

Scientists at Tomowave Laboratories use technologies based on light and sound to make imaging systems for the healthcare industry. These technologies use optoacoustic and laser ultrasonic methods to produce modalities such as laser optoacoustic ultrasonic imaging system, which uses pulses of laser light with a dark red color.

Biological tissue absorbs this light, causing it to heat-up by a fraction of one degree. The resulting temperature increase causes an increase in pressure, which generates ultrasonic (optoacoustic) waves. The imaging scanner uses arrays of transducers to measure these ultrasound waves at different locations to generate images of internal tissue of different human and animal organs, such as breast or prostate. These systems listen to the sound of light, allowing doctors to detect and diagnose cancer and other conditions.

Recently, engineers at Tomowave developed a system that combines light and sound to generate three-dimensional images of tissue submerged in the imaging module, primarily the tissue of small animals used for research purposes and development of new contrast agents or therapeutic methods.

Direct Drive Rotary Servo Table model PSR180UT

This system’s imaging module uses a 360-degree rotation to generate three-dimensional images.

Preclinical research systems rotate the object of study, while the module itself rotates in systems used in clinical settings such as breast imaging systems.

Noninvasive breast imaging systems apply the same technology to produce three-dimensional volumetric optoacoustic images and stack of two-dimensional ultrasonic images, allowing for image co-registration.

These systems produce scans at different wavelengths in minutes with minimal patient discomfort. Custom software processes the volumetric data according to the specific items of interest, which may include hemoglobin content, oxygen saturation and vasculature visualization.

The imaging system uses a PSR180UT low profile rotary servo table from IntelLiDrives to rotate the imaging module at precise constant speed, which is programmed in advance.

A real-time servo controls and continuous precision encoder output provide synchronization of the image capture with the motor’s position, which allows Tomowave engineers to reconstruct captured images in three dimensions.

IntelliDrives

www.intellidrives.com

Filed Under: Motors • servo

Tell Us What You Think!