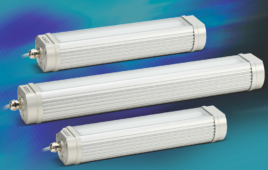

SICK introduces the new SLG-2 automation light grid. This is the second generation of the “Slim Light Grid” from SICK and offers enhanced flexibility and functionality.

Space-saving dimensions, low-profile construction, detection heights adjustable in practical increments, and a blind zone-free design ensure an easy integration in machines where space is limited. The performance of the SLG-2 with its patented optics is complemented by the integrated smart task functionality and extensive diagnostic options. With IO-Link communication as a standard, the light grid is Industry 4.0 ready.

The SLG-2 automation light grid is designed for use in logistics systems, machine building, and packaging machines. It fulfils a range of requirements demanded by integrators and OEMs with regard to ease of integration, performance, functionality, and its future-proofing capabilities.

Offering excellent resolution and a fast response time, the SLG-2 enables high-performance detection and measurement solutions. The light grid is available in beam separations of 10 mm, 25 mm, and 50 mm.

In “multiple-cross-beam” mode, the light grid not only achieves a resolution of 6.5 mm, but can also reliably detect flat objects that can be thinner than 1 mm. An optical element developed and patented by SICK ensures maximum resistance to ambient light, reflections, or interference from other opto-electronic sensors in the surroundings. The SLG-2 also offers short response times, ranging from 2.1ms to 20ms, depending on the number of light beams. This means that objects can be reliably detected even in high-speed processes.

With dimensions of 12mm x 24mm, the SLG-2 is one of the most compact automation light grids of its kind on the market. Detection heights are between 100mm and 2,400mm and can be adjusted in 100 mm increments.

The user can also choose between the slim variant with light emission through the thin side of the device or the flat version with the optics opening in the flat housing profile. This makes mechanical installation easy, especially since the SLG-2 has no blind zones as the sender and receiver elements reach right up to the edge of the housing.

With the SLG-2, all light beams can be read out individually and the beam status can be transmitted via the IO-Link interface. This raw data and measuring functions integrated in the light grid provide the user with the greatest possible flexibility for solving tasks like width, height, and profile measurement for position determination and the classification of objects.

Using the integrated smart task logic, it is also possible to define different zones within the light grid, assign functions to them, logically link zone signals to one another, and provide the values as output signals. Among many other applications, these functions are used to distinguish between pallets and loads or to detect process errors in depalletizing systems.

In use, the SLG-2 provides extensive diagnostic information for condition monitoring and preventive maintenance. The Quality of Run alarm reports changes in detection quality.

The light grid monitors limit values for operating hours and temperatures. It reports possible sender-receiver synchronization errors, teach-in or hardware problems, or invalid process data. This guarantees high, uninterrupted availability of the light grid.

SICK

www.sick.com

Filed Under: Lights • signal lamps • indicators