The compact IRB 460 claims to be the fastest palletizing robot on the market. Capable of up to 2,190 cycles per hour, this 4-axis robot is perfect for high-speed end-of-line palletizing and bag palletizing of products that weigh up to 50 kg. With a reach of 2.4 m and a maximum payload of 110 kg, the IRB 460 occupies 20% less floor space and runs 15% faster than its nearest rivals.

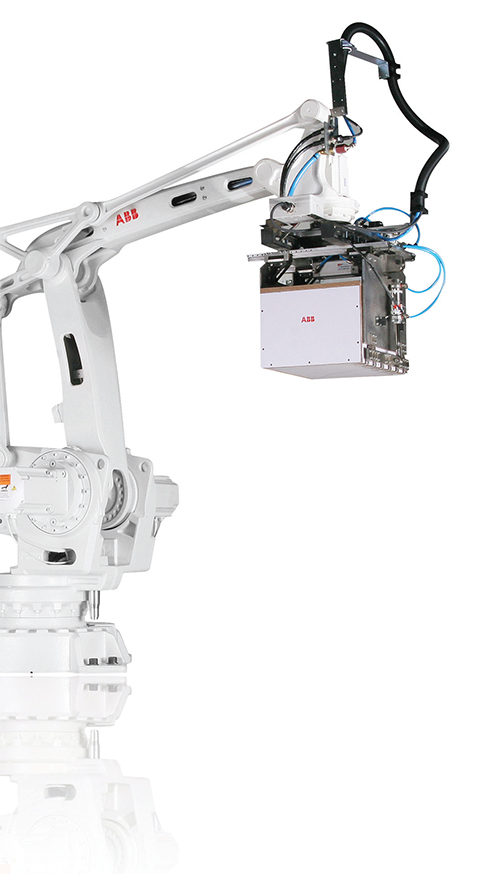

The IRB 760 is a 4-axis high output, full-layer palletizing device with a payload capacity of 450 kg and a reach of 3.2 m. It has a high inertia wrist to rotate heavy and large products fast. Thus, it is well suited to such palletizing applications as beverage handling.

Released at the same time, the RobotStudio Palletizing PowerPac has merged 13 years of palletizing software work (FlexPalletizer & PickMaster5) with the virtual programming environment of RobotStudio. This new PowerPac allows users to configure, simulate and program robots and grippers for palletizing solutions, in one step, with little or no robot programming experience required. What used to take days will now take minutes. The system will also allow potential users to validate the performance of their palletizing system before risking any equipment investments.

ABB Robotics

www.abb.com/robotics

::Design World::

Filed Under: Factory automation, ENGINEERING SOFTWARE, Motion control • motor controls, Mechatronics

Tell Us What You Think!