The two new developments in fused deposition modeling (FDM) technology announced today by Stratasys may at last help 3-D printing realize its potential as a manufacturing tool for mainstream aerospace and automotive products. While the two advanced technology demonstrators they unveiled address two very different sets of manufacturing requirements, they are both capable of building bigger, stronger, more affordable parts at speeds that are over an order of magnitude faster than any other FDM machine available today.

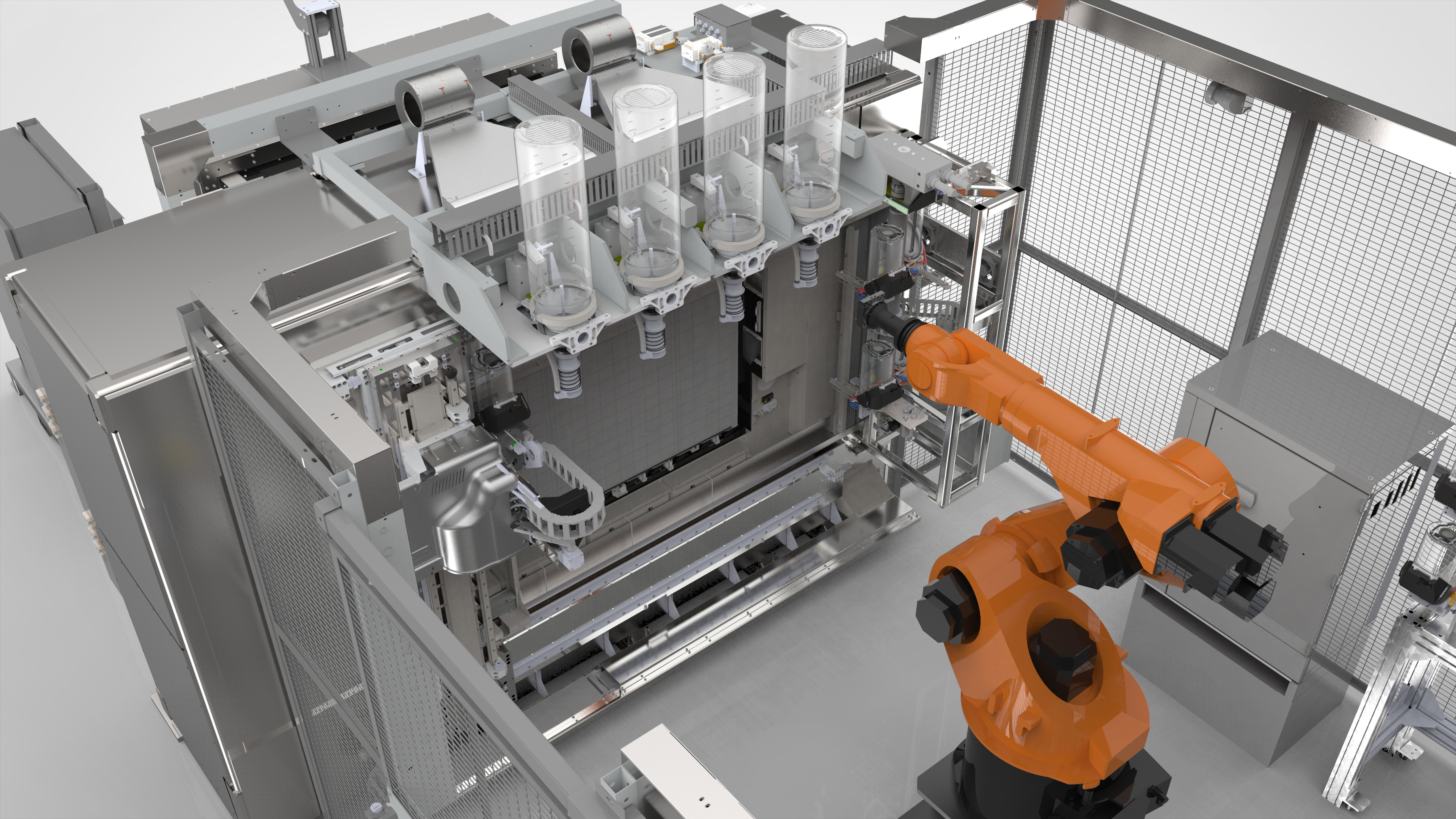

Stratasys’ Infinite-Build 3D Demonstrator for Large Thermoplastic Parts and Tools. Photo: Stratasys

3-D Goes to Great Lengths

Stratasys’ Infinite-Build 3D Demonstrator for Large Thermoplastic Parts and Tools addresses the need for large lightweight thermoplastic parts with highly repeatable mechanical properties. Instead of laying up its parts along the vertical axis, the Infinite Build demonstrator’s 3’x4’ build platform is placed sideways and pulls away from the fabrication area on a horizontal track as the part is printed. As a result, the length of the part is only limited by the length of the track and its related support system. Stratasys says that the present system can fabricate parts as long as 50’ and that production systems may be capable of even greater lengths.

The system’s extruder mechanism is equally unique and does away with the conventional filament that serves as feedstock for most FDM machines. Instead of a heated print head, it has a screw extruder which is fed a stream of micro-pellets which are liquefied primarily by shear force before they are applied to the build area. Using shear as the primary liquefaction mechanism enables lower-temperature operation for less material degradation and faster build, as well as much better control over volumetric output.

The demonstrator unit’s print head can draw its micro-beads from four separate sources, enabling multi-material/multi-color fabrication. At present, the system is using Stratasys’ Ultem 9085 PEI build material plus a specialized support material whose mechanical properties are suited for horizontal build environments.

Since the screw extruder can push out material much more quickly than a conventional mechanism, it can achieve build speeds that are over 10X faster than the fastest conventional FDM system. But in order to have precise dimensional control at these extremely high flow rates, Stratasys had to also carefully control the thermal environment surrounding the build area using a 5-sided oven which provides a constant thermal gradient for consistent cooling.

Thanks to all these capabilities, the Infinite Build demonstrator can build large parts in hours rather than days, and deliver a much higher degree of consistency and repeatability that can more easily meet the requirements of aerospace, automotive and other hi-reliability applications.

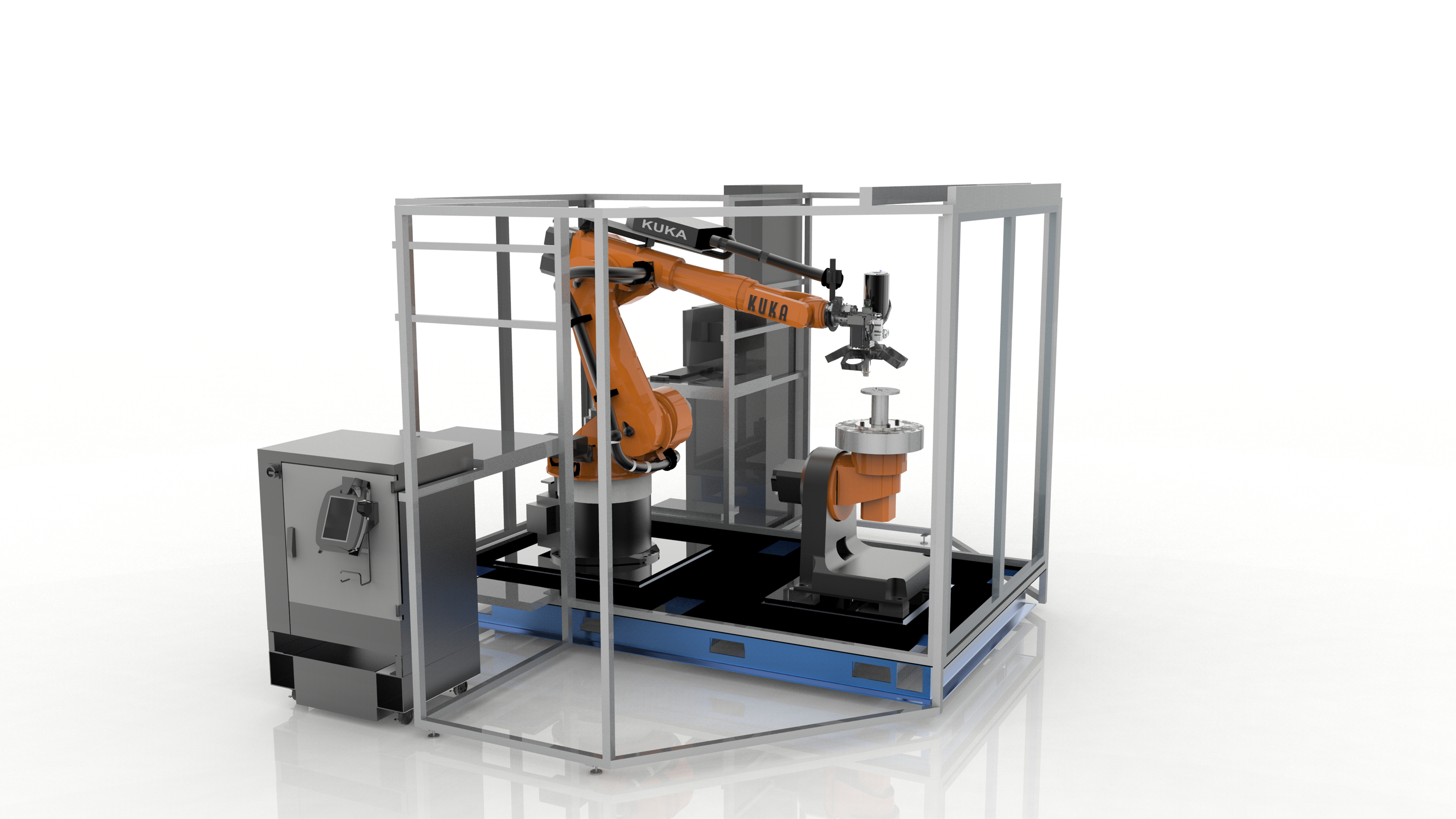

Stratasys’ Robotic Composite 3D Demonstrator. Photo: Stratasys

Building Strong

Stratasys’ other Demonstrator uses an 8-axis robotic system to produce composite parts that have one or more degrees of directional strength. Known as the Robotic Composite 3D Demonstrator, the prototype system extrudes thermoplastic (polyamide – Nylon) containing chopped carbon fibers which align with the direction of flow to provide directional strength which enables production of stronger, lighter parts. The current system can use either conventional filament or micro-pellets. In addition, Stratsys says that there is a clear roadmap to a system that uses continuous fiber which will produce even stronger parts.

Like its companion, this Demonstrator does not follow the simple 3-axis X-X-Z coordinate system used by most FDM machines. Instead, the build surface is an 18-inch table that rests on a 2-axis rotary positioner while a 6-axis robot controls the posiiton of the Demonstrator’s extruder head. This 8-axis system eliminates the need for discrete layers, enabling individual features to be constructed as discrete elements (instead of as discrete layers), each with their own directional properties. In addition, the highly-articulated extruder head allows complex parts to be built from the inside out.

As a result, the 3D Composite Demonstrator offers fast production speeds that are further enhanced by the elimination of layer transition times and of most support materials. And, unlike conventional printers whose print volume is limited by the system’s framework, the Composite Demonstrator’s build area is only limited by the reach of the robot.

Although the current version of the Demonstrator only builds parts from Nylon, Stratasys says that they will quickly adapt the process to use other qualified materials currently in use for automotive and aerospace applications, including PEEK and PEKK.

First Commercial Applications

Given the Infinite Build Demonstrator’s capabilities, it’s no wonder that aerospace manufacturer Boeing played an influential role in defining its requirements and specifications, with an eye towards meeting their needs for production of low-volume, customized, lightweight flight parts. One of the first applications for the system is expected to be the large, complex plastic panels used to finish the interiors of today’s aircraft, and there is interest in using them in trains, busses and other large-capacity transportation systems. Ford Motor company is also exploring automotive manufacturing applications for the Infinite Build Demonstrator.

Boeing and Ford will also be exploring how to use the Robotic Composite 3D Demonstrator to fabricate structural parts for aerospace and automotive applications. Details on precisely what those applications would be were not available at the time of this briefing.

Filed Under: Industrial automation