Where do super powers come from? For Superman, it was his Kryptonian body that allowed him to harvest energy from the sun and obtain super strength. For Batman, it was his superior technology that allowed him to best his opponents.

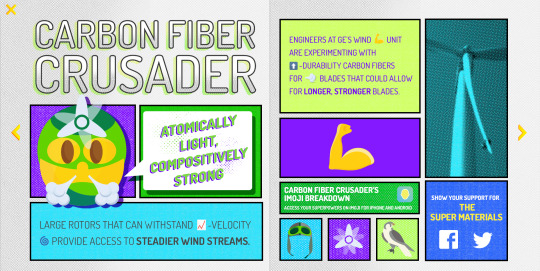

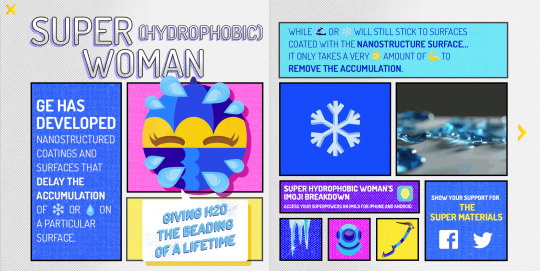

But truth can be stranger than fiction. New supermaterials developed by GE scientists – like “super” ceramics called CMCs that can work inside a jet engine, fourth-generation carbon fiber composites and water-repellent, or superhydrophobic coatings – bestow what seems like superpowers on everything from jet engines to wind turbines and power plants. (GE calls this idea of sharing the same advanced technologies between different products and businesses the GE store.)

Obviously, GE is not developing materials with super properties just for the thrill of it. The company has spent billions of dollars to come up with materials like CMCs and uses them to get a competitive edge.

For example, the LEAP jet engine, the world’s first engine with CMC parts, has already become the bestselling jet engine in GE history, even though it won’t enter service until 2016. The engine was developed by CFM International, a joint company between GE and France’s Snecma (Safran), and CFM has received orders for 9,550 LEAP engines valued at $134 billion, to date.

But big business doesn’t mean the company can’t have little fun with the materials. That’s why GE decided to create a new class of superheroes based on the materials’ qualities.

The company timed the coming out party for the characters, which include Captain CMC, the Carbon Fiber Crusader, and the Super Hydrophobic Woman, for Comic-Con International, the World’s Fair for comics lovers starting this week in San Diego.

Take a look at the graphics below to learn more about these characters and the stuff they are made of.

Filed Under: Materials • advanced