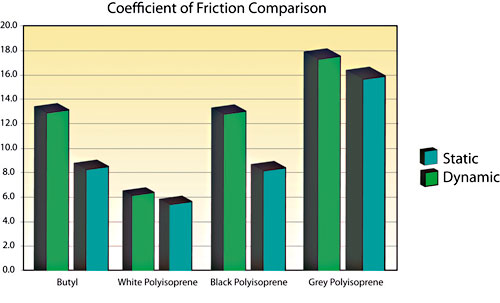

Frictional force is directly related to the coefficient of friction (COF) of the material. For the most part COF (measured using ASTM D1894 test) is what Minnesota Rubber and Plastic (MR&P) uses for comparisons as it is a sealing system measurement rather than a measurement of the property of the material. When moving a surgical instrument or cannula through a trocar seal, the inertia that is takes to start moving it is different than the inertia that it takes to stay moving.

This is called static (starting) COF and the dynamic (moving) COF. This difference will vary by material, application, and lubrication state and/or coating and is a central element of the “feel” of the trocar. Ted Ahrenholtz of MR&P says, “Contrary to most thinking, sliding a rod (cannula) through a seal is never smooth. While it may feel smooth, in reality it is not. There is always a stick/slip force that is present where the seal flexes to accommodate the cannula’s movement, which then rebounds back to a stable state. In general, the smaller the difference between the static and dynamic COF, the smoother the inertia feels.

“The best seal design and the most appropriate material formulation will minimize this stick/slip phenomenon. However, it is important to note that some degree of friction will always be present in all seals used for this purpose.”

Surface finishes and coatings on the trocar seal material can reduce the coefficient of friction. The smoother the surface, the greater the COF. A matter finish can reduce the amount of friction on a very smooth surface. However, maximum friction reduction is achieved with the correct coatings applied to the material surface. Depending on the substrate and its application, polytetrafluoroethylene (PTFE), parylene, chlorination and MR&P’s proprietary processes can reduce friction by as much as 90%. Ahrenholtz adds, “Friction in these pass through seals is complex. The amount of force it takes to slide one surface past another is affected by many variables influencing the surgeon’s skill and quality of the procedure.”

Minnesota Rubber and Plastics

www.mnrubber.com

::Design World::

Filed Under: Seals • O rings, Medical-device manufacture, Seals

Tell Us What You Think!