What is synthetic diamond?

Synthetic diamond is a lab-grown supermaterial that mimics and improves upon the chemically and physically inert characteristics that make natural diamond a key material for various scientific applications. Diamond synthesis enables precise control of the properties so that diamond can be specifically engineered for different industrial applications.

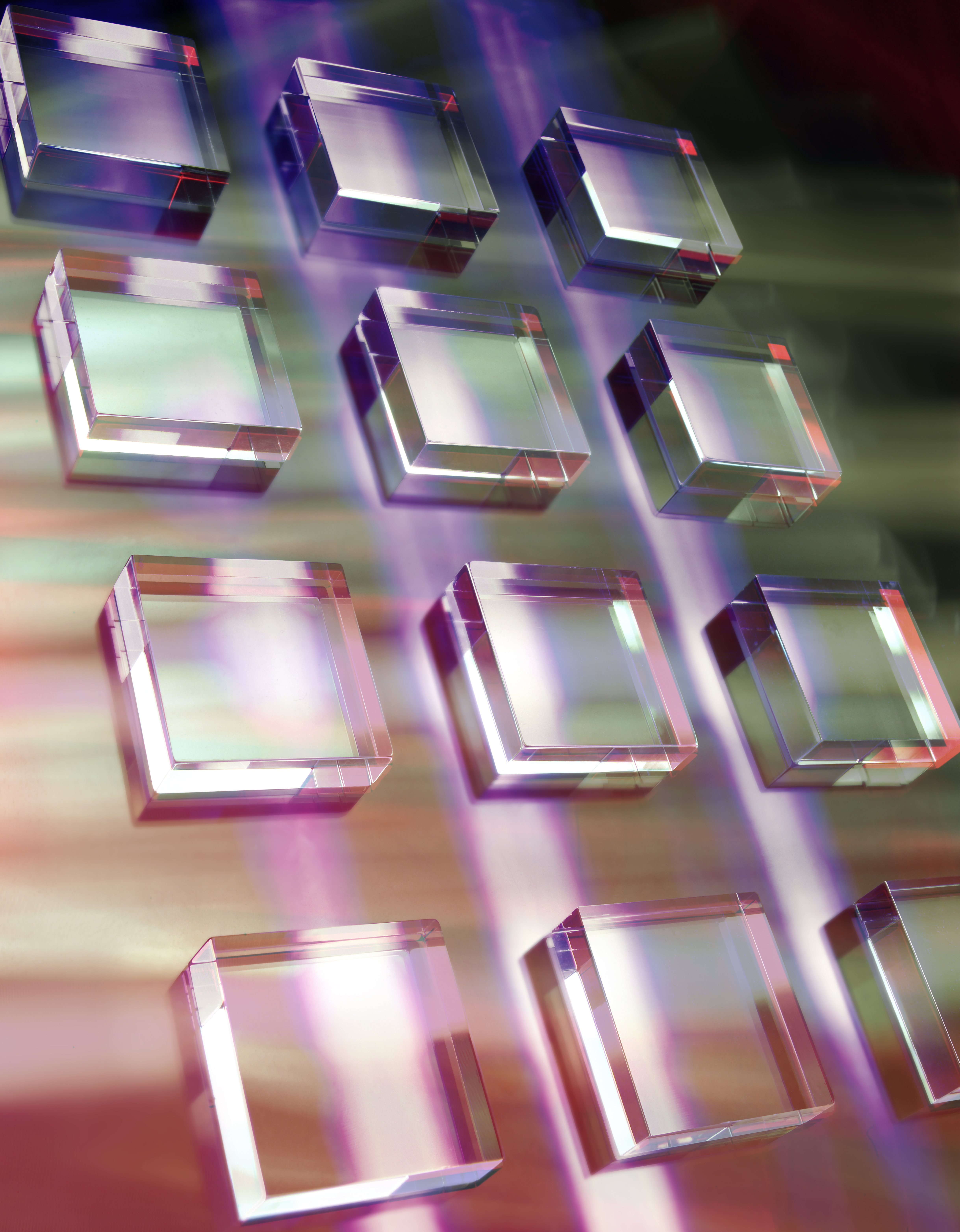

Single crystal chemical vapor disposition (CVD) diamond plates (All images courtesy of Element Six)

Physical properties of synthetic diamond

The unique combination of properties makes synthetic diamond one of the most versatile supermaterials available in the world. Element Six continues to develop various grades of synthetic diamond and research and manipulate its extreme properties to be uniquely suited to advance performance and economic advantage in various applications. Some of the characteristics unique to synthetic diamond include:

- The broadest electromagnetic transmission spectrum of any material

- A wide electronic band gap (it carries very low current even under high voltages)

- The ability to combine/dope with boron and take on a similar electrical conductivity to metal

- The highest known resistance to thermal shock

- The highest known thermal conductivity

- Low thermal expansion

- Low dielectric constant and loss

- High electrical carrier mobility

- Chemical and biochemical inertness

- Excellent electrical insulator properties

- High stiffness combined with being hardest known bulk material

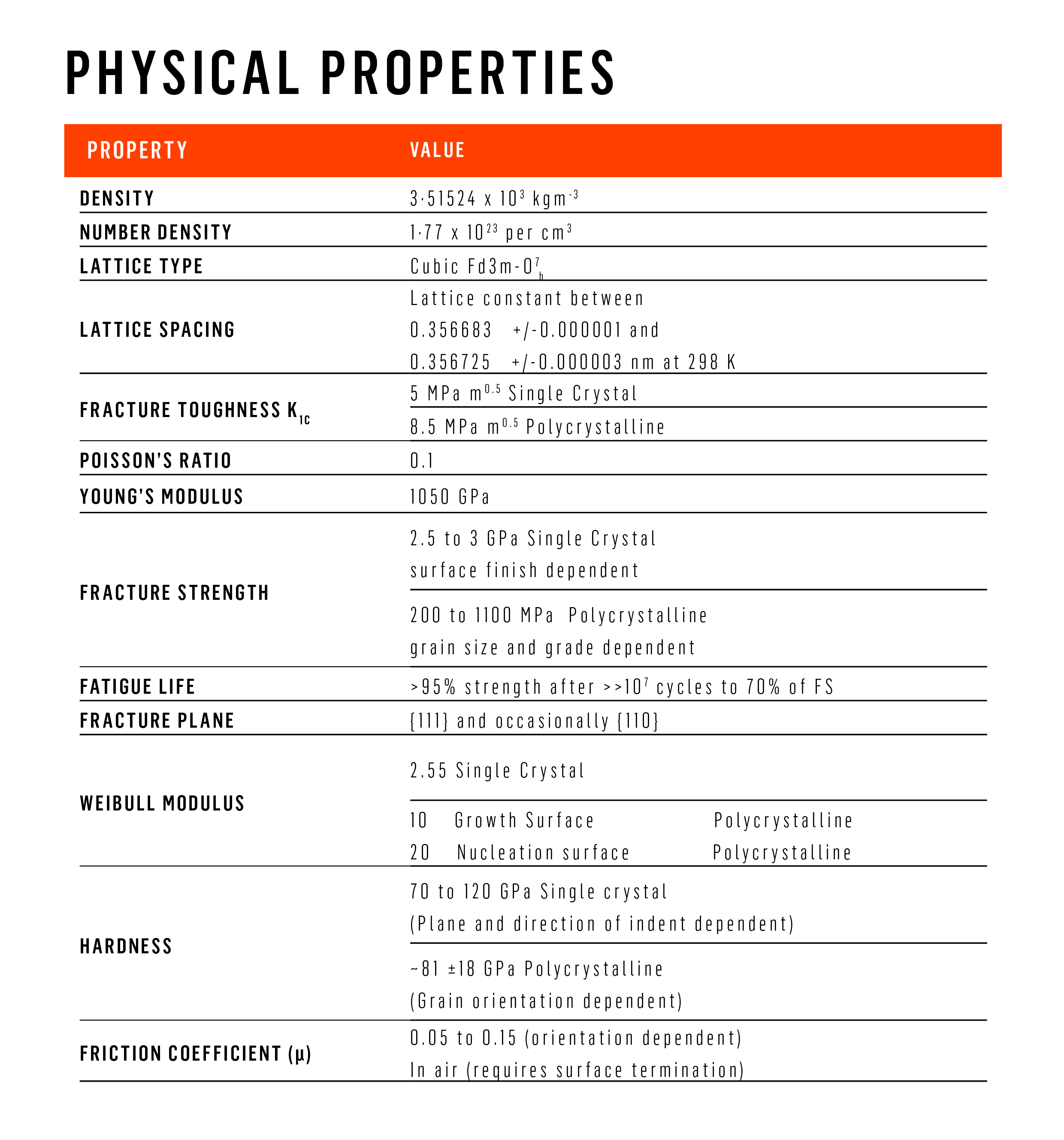

The physical properties of synthetic diamond

Distinctions between mined and synthetic diamond

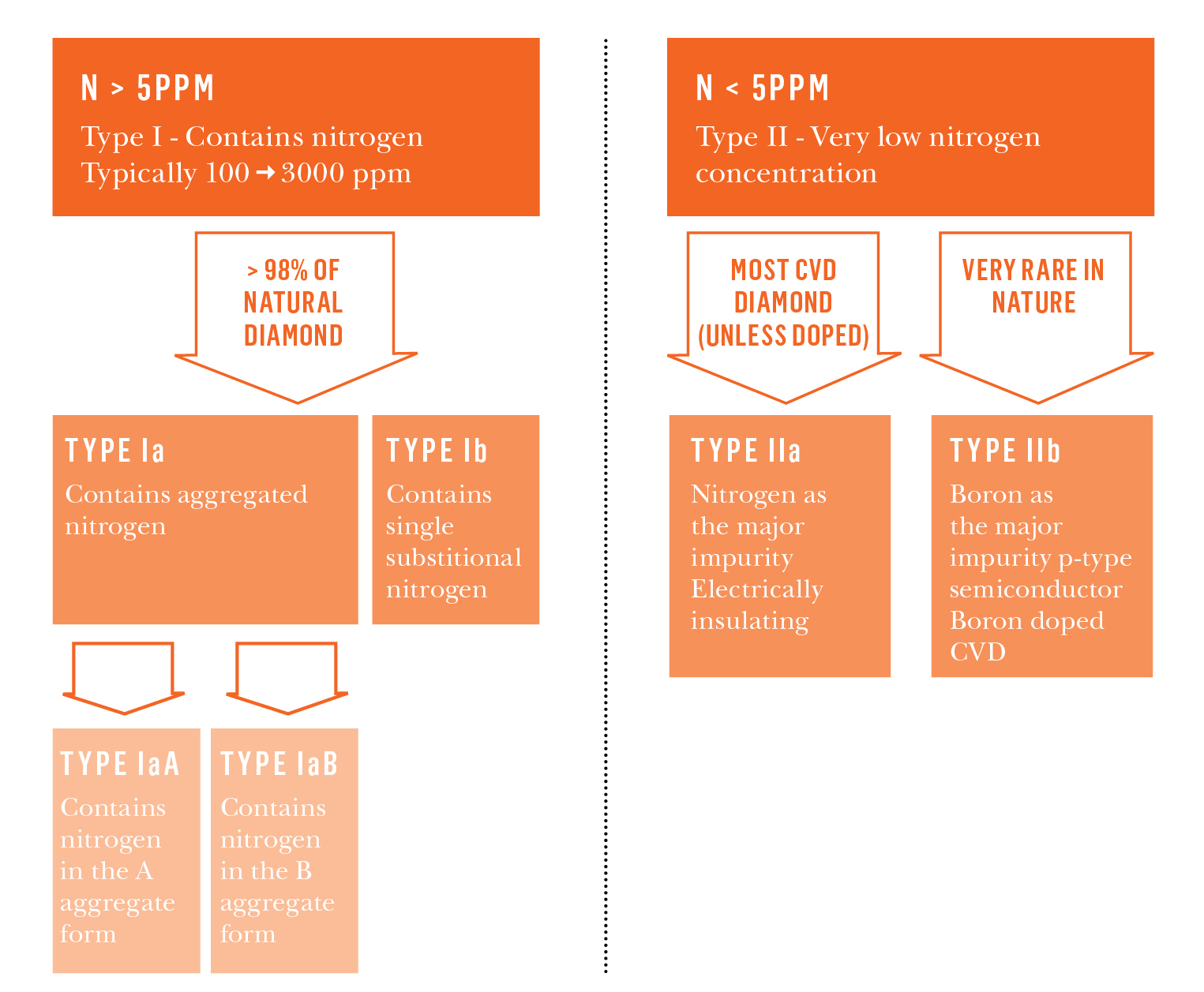

Natural diamond has an inherent variability and scarcity that limits its use in engineering applications. Developments in synthesis processes have enabled the production of consistently engineered synthetic diamond through two methods: high pressure and high temperature (HPHT) and chemical vapor disposition (CVD). Natural diamonds are classified according to their optical properties, with most being Type I and having an absorption edge of around 330 nm, and a small group being Type II with an absorption edge of about 220 nm. This classification has evolved over the years to include other predominant defects such as nitrogen and nitrogen clusters. In some ways, this classification also applies to synthetic diamond, however the simplicity of this classification can’t distinguish between the many polycrystalline and single crystal grades of synthetic diamond that are developed with specific tailored properties.

Differences between Type I and Type II diamond. Most HPHT grown synthetic diamond fall in the classification of Type Ib, while most CVD grown fall into Type IIa unless doped with boron to create IIb.

How are synthetic diamonds made?

To date the majority of synthetic diamonds are made by HPHT methods. HPHT aims to mimic the thermodynamic conditions in nature that diamond forms in, but with the addition of a molten metal solvent/catalyst to reduce the large kinetic barrier and act as transport media for dissolved carbon. Through the other method of synthetic diamond synthesis, CVD, growth conditions are created by thermal disassociation of hydrogen, and a gaseous source of carbon in plasma, with a gas temperature above 2000°C. After nearly four decades of research, this method has emerged as a preferred process due to the growth rates and high control over purity that enable the creation of high quality, free-standing polycrystalline and single crystal CVD.

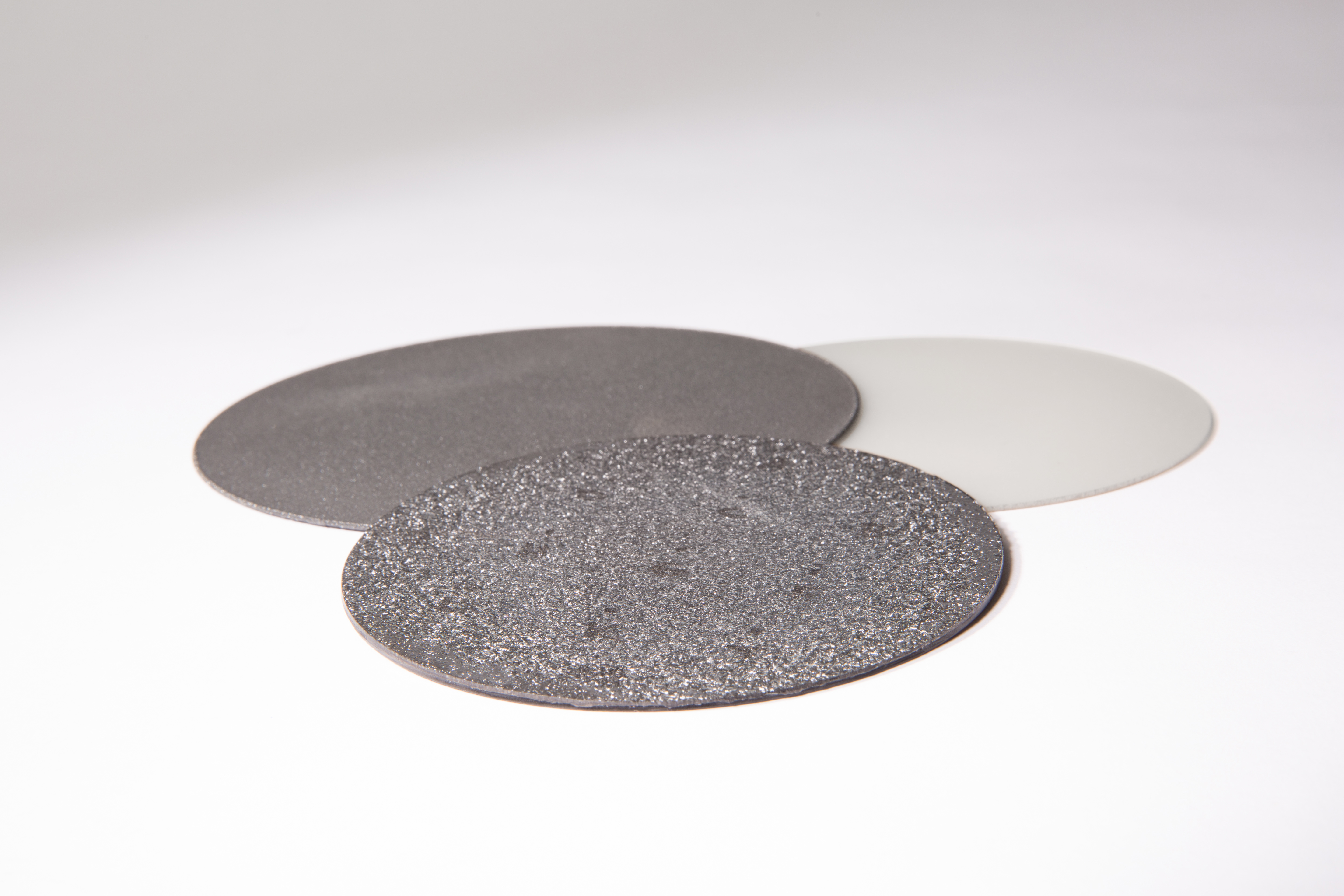

Various grades of synthetic polycrystalline diamond grown by CVD

An Element Six technician growing diamond using HPHT

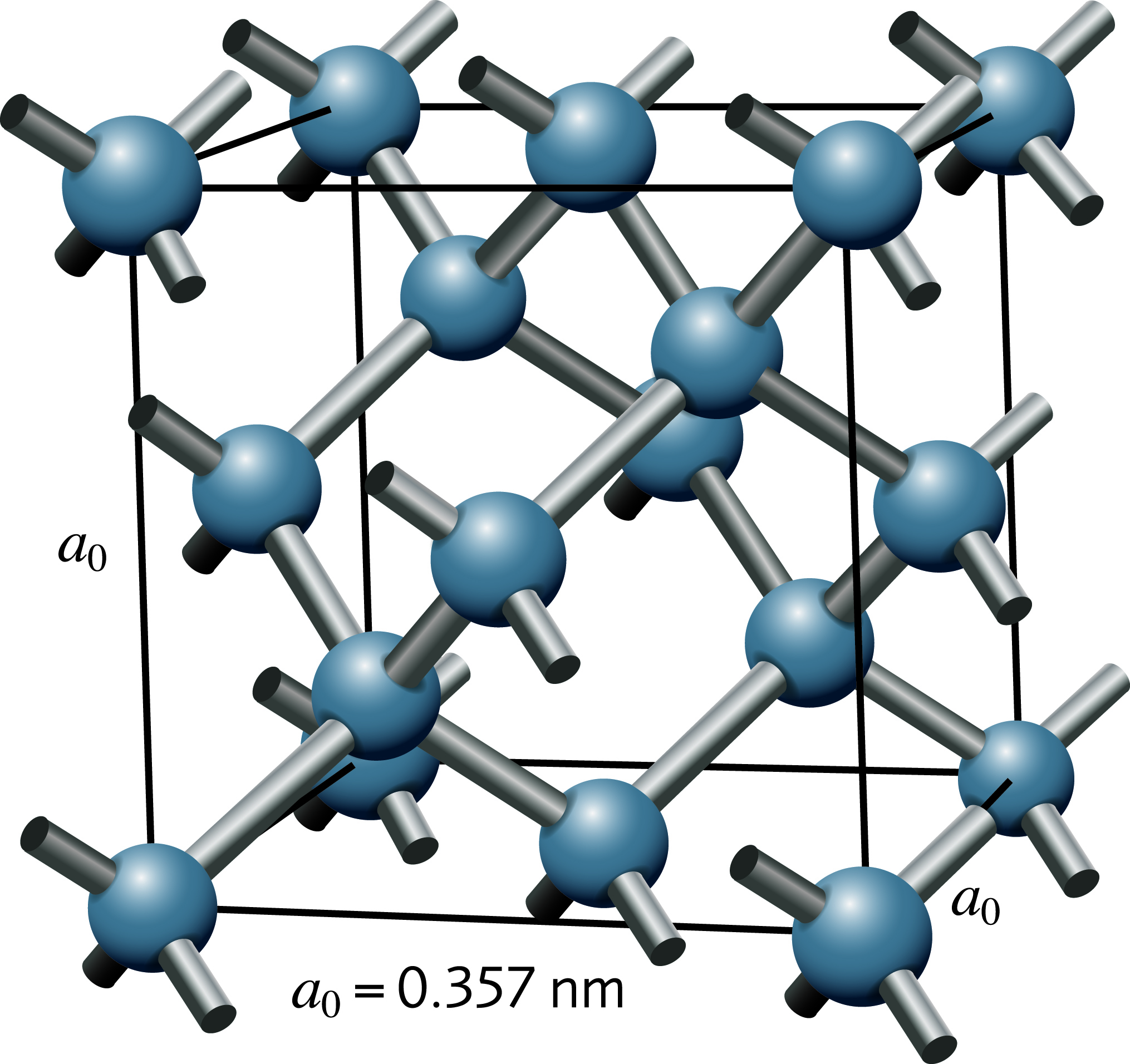

What makes synthetic diamond so strong?

Synthetic diamond is the hardest material on the planet. Synthetic diamond’s unique properties stem from its rigid lattice structure. Carbon atoms linked together in a dense tetrahedral arrangement make it incredibly strong. The exceptional hardness of synthetic diamond has inherent advantages in mechanical and abrasive applications such as cutting, drilling and grinding, while also adding significant value in technological applications enabling stronger, more scratch resistant laser windows and thinner heat spreaders that can support a larger mechanical and thermal load in thermal management applications

Synthetic diamond’s hardness comes from its carbon atoms forming a rigid cubic lattice structure

How can synthetic diamonds be used?

Synthetic diamond’s unique properties make it ideally suited for a wide variety of applications including precision machining, drilling/crushing, optics, acoustics, electronics, sensors and water treatment. The next sections take a closer look at the specific properties of diamond and the advantages/uses of those properties in certain industries.

Thermal properties

With the highest known thermal conductivity (four times higher than copper), synthetic diamond is the ideal material for thermal management applications requiring optimum performance. Considering 50 percent of electronic failures occur due to heat-related issues, CVD diamond is invaluable in all types of electronic and electrical applications, including telecommunications and microelectronic devices, where the build-up of heat can destroy delicate circuitry or severely impair performance. Properly dissipating heat is also key to enabling smaller, more powerful electronic devices.

Electronic properties

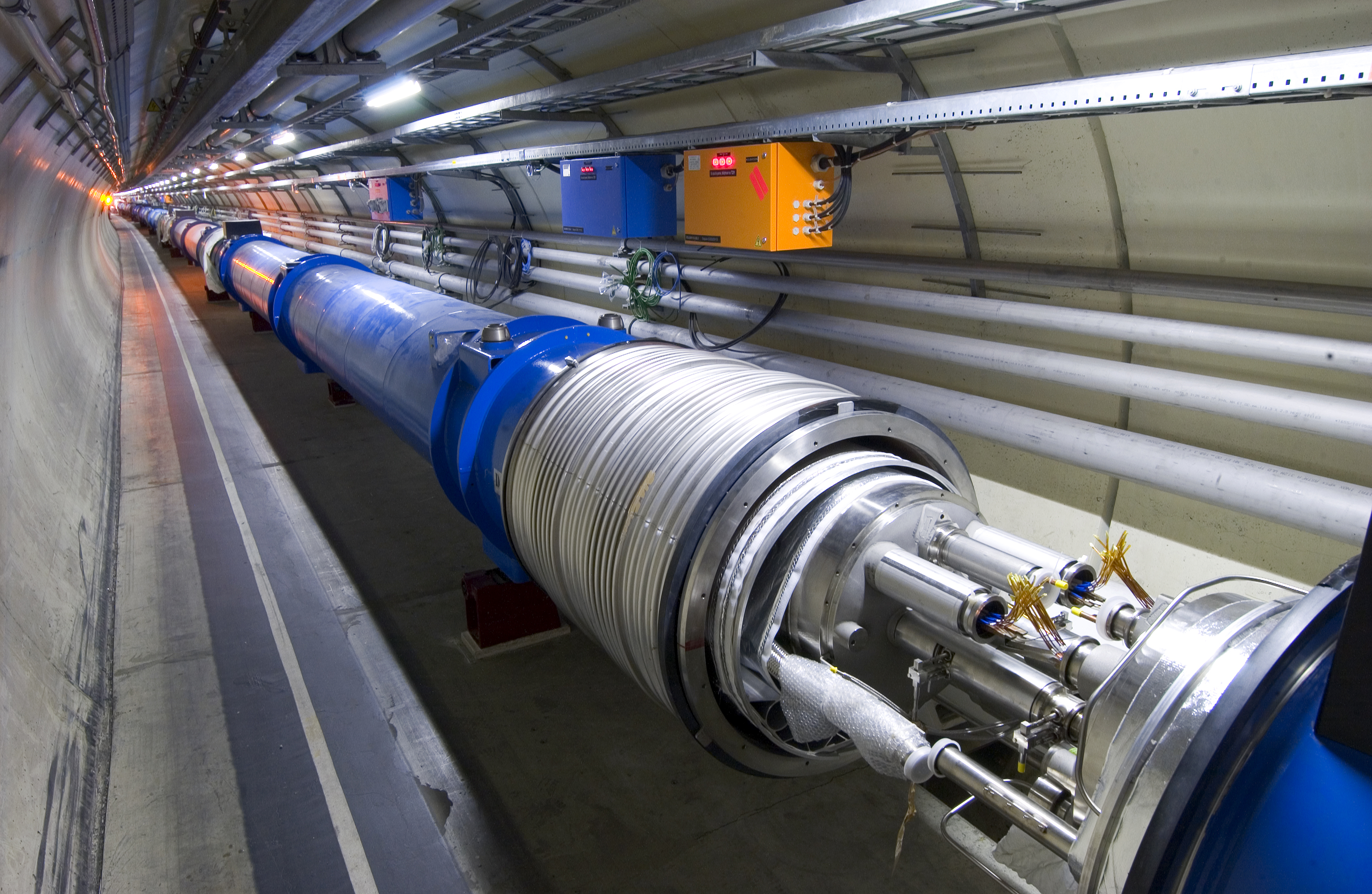

Synthetic diamond’s electrical properties include a low dielectric constant and loss, high electrical carrier mobility and a wide electronic bandgap (meaning low leakage currents even under high voltages). Element Six has also engineered a range of electronic grade CVD diamond material that can be used in a variety of demanding radiation detection applications including high energy physics, neutron and other high energy/radiation detection and homeland security applications. Synthetic diamond is also at the forefront of advances in quantum mechanics, due to certain spin defects such as nitrogen vacancy centers that can be easily manipulated and controlled.

Electrochemical properties

Synthetic diamond is chemically and biologically inert and can survive in severe physical, chemical and radioactive environments that would destroy lesser materials. Its unique electrochemical properties enable the efficient oxidation of organic and inorganic compounds and Element Six investment has resulted in the successful application of a synthetic diamond-based product in industrial and household water treatment. Synthetic diamond also has high efficient wastewater treatment applications for low volume, highly contaminated industrial wastewater that cannot be treated by biological methods. One method developed by Element Six, the Diamox treatment process, is capable of near mineralization of dissolved organic compounds, allowing opportunities for direct discharge or even reuse of wastewater.

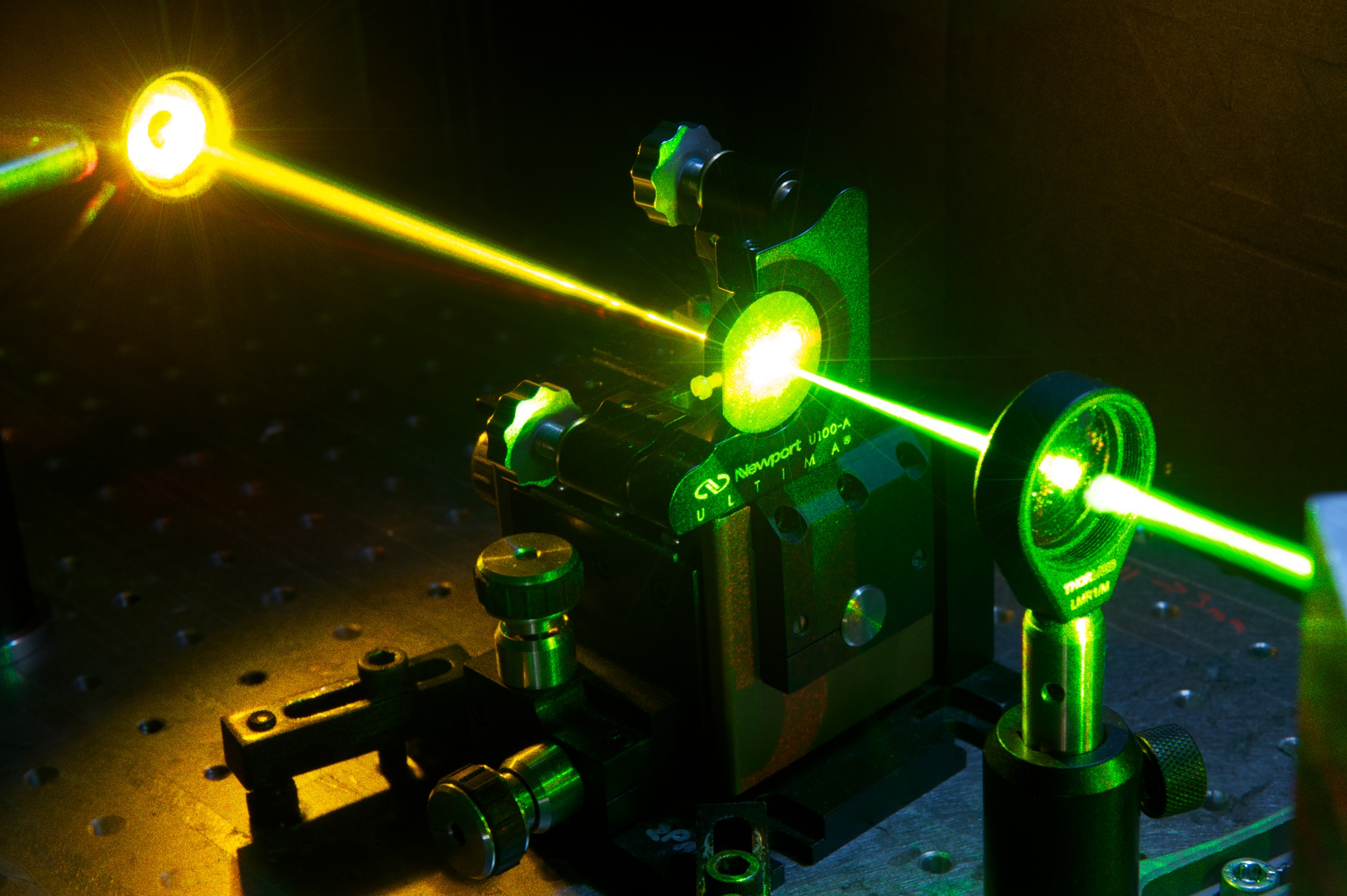

Optical properties

Synthetic diamond has the widest spectral band of any known material—extending from ultraviolet to far infrared and the millimeter-wave microwave band. Coupled with its mechanical and thermal properties, this makes it the ideal ‘window’ material for many industrial, R&D, defense and laser applications, particularly in the production of laser optics where synthetic diamond provides optimum exit windows for CO2 lasers, such as those used in automotive cutting applications. Element Six single crystal synthetic diamond and polycrystalline CVD diamond solutions are found at the core of high power CO2 lasers, disk lasers and solid state lasers, and enable a stable and enduring high optical quality of the laser beam.

Synthetic diamond detectors are used in high energy physics, ionizing radiation and deep ultraviolet monitoring

Engineered single crystal CVD diamond, with ultra-low absorption and birefringence combined with long optical path lengths, has made Monolithic Diamond Raman Lasers a practical reality

Filed Under: Industrial automation