B&R added a safety solution to its portfolio for agricultural machinery. At Agritechnica 2019, the company will present its X90 controller with integrated safety technology. A variant of the X90 controller is available with an integrated B&R SafeLOGIC safety controller. To create the corresponding safety application, the user simply connects ready-made software components using ladder…

Controller and multi-touch HMI in one device

The modern multi-touch HMI is available with clear or anti-reflective glass, and is suited for premium machine designs. The touch screen reacts precisely and reliably even when operated with thick leather gloves. Gestures such as zoom or swipe provide an intuitive user experience. The Power Panel C50 is available in widescreen format in four different…

B&R brings safety to delta kinematics

B&R offers SafeROBOTICS functions for tripods to safely monitor all types of delta kinematic systems. Serial axes can be also be included in the calculations, for example when tripods are mounted on moving platforms. Safe robot monitoring is implemented using the safety functions Safely Limited Position, Safely Limited Orientation, Safely Limited Joint Position and Safely…

Integrated automation solutions smart manufacturing

At the Hannover Messe trade fair, B&R will show how a conventional plant can become a smart factory in Hall 9, Booth D26. B&R enables the automation of all production areas and allows them to interact seamlessly. B&R’s portfolio makes it easy to implement efficient, high-quality production down to batch size one, ensure safe human-machine…

Safety module saves space in the control cabinet

The new X20SO6530 digital output module provides six safety relays on a unit with the X20’s standard 25 mm width, allowing B&R to offer a cost-effective and space-saving solution for applications where numerous floating signals are needed. To meet safety requirements, positively driven feedback contacts must be evaluated in a manner that is appropriate for…

B&R MapleSim Connector simplifies model-based machine development

B&R simplifies model-based machine development with the new B&R MapleSim Connector. It considerably reduces the time spent modeling machine components. Machine functions are easy to program and deploy. B&R MapleSim Connector is seamlessly integrated in the B&R Automation Studio environment. B&R MapleSim Connector makes it efficient for B&R customers to integrate the MapleSim tool from…

B&R features automation advances to maximize packaging productivity at PACK EXPO 2017

Highlights include HTML5 based HMI, Industrial Internet of Things connectivity, flexibility, open robotics integration with SuperTrak™ industrial transport, Augmented Reality and networked safety. At this year’s PACK EXPO International show, September 25- 27, Las Vegas Convention Center; Las Vegas, NV, B&R Industrial Automation Corp. will exhibit automation technologies that are trending in packaging machinery design…

Visit B&R in Chicago at IMTS 2016

Visit the B&R booth to learn about the integrated machine control platform and advanced technologies At this year’s International Manufacturing Technology Show (IMTS), from September 12-17 in Chicago’s McCormick Place, B&R Industrial Automation Corp will exhibit its innovative automation solutions at booth E-4115. B&R specializes in standards-based, scalable and modular control systems integrating CNC, logic,…

Develop application software significantly faster

K 2016: B&R presents mapp Technology for the plastics industry At the K 2016 trade fair from October 19-26, in Hall 12 / Booth B16, B&R will be demonstrating how modern plastics machinery can produce a variety of products with no mechanical changeover. Modular software blocks simplify the development of new programs and reduce development…

B&R Industrial Automation Corp to exhibit innovative automation solutions at IMTS

The efficiency of CNC machine control development and operation can be improved by replacing traditional systems with an integrated, multifunctional control platform. Traditional systems include logic, machine-specific technologies, point-to-point movement, path-based interpolated movement and visualization, each requiring hardware interface and communication software to work together. With B&R’s integrated solutions, a single software development environment, Automation…

Software Blocks for development of plastics machinery

K 2016: B&R presents mapp Technology for the plastics industry At K 2016, from October 19-26, B&R will be demonstrating how to greatly simplify the development of applications for injection presses, extruders and blow molding machines (Hall 12, Booth B16). Modular software blocks can reduce development times by an average of two-thirds. Develop 3-times faster…

Automation solutions for Maritime 4.0

SMM: B&R presents web-based HMI solution and integrated shipboard control system In Hall B6, Booth 305 of the SMM trade fair, B&R will be presenting its new, 100% web-based HMI solution, mapp View, as well as its scalable APROL process control system. Solutions from the automation specialist help builders of machines and equipment create smart…

New solutions for azimuth control

WindEnergy: B&R presents new solutions for azimuth control At the WindEnergy expo in Hamburg (Hall B6, Booth B6.393), B&R will be demonstrating how wind turbine wear can be minimized through optimal yaw control. This is made possible by intelligent control concepts based on the ACOPOS P3 servo drive. The ACOPOS P3 is designed to operate…

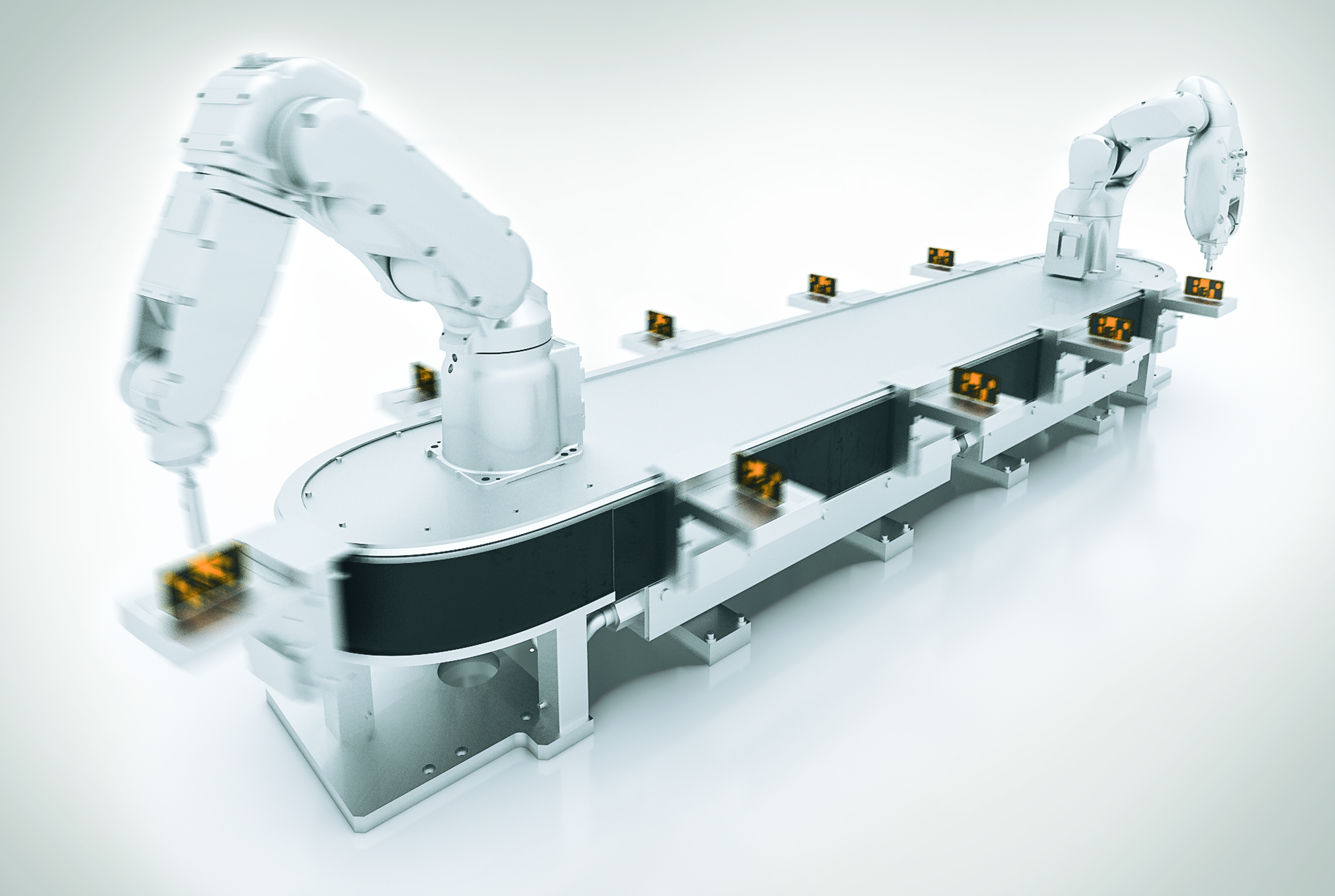

Precisely synchronize conveyor belts and robots

An increasing number of processes in production lines require synchronization with conveyor belts. Ensuring the high levels of speed and precision needed to accomplish this previously required highly complex control solutions. Production lines with conveyor belt tracking have an advantage: Since the production process never comes to a stop, they can achieve higher production volumes.…

COMAU and B&R assimilate robotics into machine control

With the introduction of openROBOTICS, partners COMAU and B&R are opening up new dimensions of robotics integration for machinery and production lines. The solution is based on a…

The post COMAU and B&R assimilate robotics into machine control appeared first on Robotic Tips.

![]()

B&R control modules add safety functions when retrofitting wind turbines

The recent B&R safety system provides a clear technological advantage with the highest level of safety. It also allows implementing intelligent safety concepts that would not otherwise be possible.

Windpower Engineering & Development

![]()

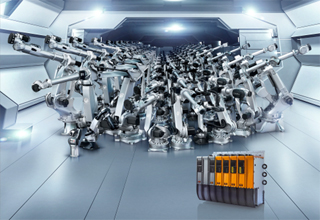

10,000 COMAU robots controlled by B&R

Comau and B&R celebrate a productive partnership with a promising future As the collaboration between COMAU Robotics and B&R continues to mature and expand, the companies can already boast ten thousand units installed and operating all around the globe. This achievement underscores the quality of COMAU products, which rely on powerful, accurate and reliable control…

B&R mapp technology now includes robot-kinematics functions

B&R is expanding its mapp technology portfolio to include robot-kinematics functions for all the most common robot kinematic systems. Not only does this allow users to commission robots…

The post B&R mapp technology now includes robot-kinematics functions appeared first on Robotic Tips.

![]()

EWEA: B&R safety technology saves up to 50%

Boost in efficiency for wind power At the EWEA trade show in Paris, France, B&R will present integrated safety technology that allows operators of wind turbines to save 30 to 50% in costs for safety systems. From November 11 – 17 at Booth S13, the automation specialist will demonstrate how field deployment of service technicians…

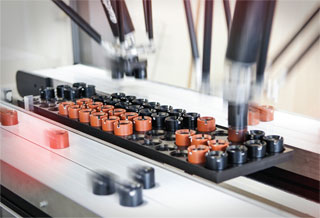

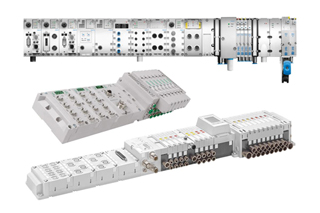

POWERLINK enables seamless integration of valve terminals

Pneumatic system solutions with B&R In cooperation with partners Festo, ASCO, Numatics and Aventics, B&R has created the perfect solution for seamlessly integrating pneumatic solutions in an automation system. Customers benefit from extremely easy handling, high clock accuracy throughout the system and maximum freedom in the selection of hardware. Valve terminal families can easily be…

B&R simplifies packaging automation

North American packaging machinery users and OEMs benefit from familiar ladder logic programming, but new packaging-automation software is easier. As machine functionalities become more sophisticated, ladder programs can become…

![]()

Industrial PC from B&R awarded DNV GL certification

B&R’s Automation PC 910 has been awarded DNV GL certification for maritime applications. The industrial PC has been certified in accordance with GL 2010, IACS UR E10. Additionally, DNV GL confirms its compliance with IEC 60945, including the specified Compass Safe Distance. The Automation PC 910 is now available for use in many maritime and…

Homing once is enough

With SafeMOTION Release 1.9, safety functions for the ACOPOSmulti servodrive family have been updated. In addition to two new functions—Remanent Safe Position (RSP) and Safely Limited Acceleration (SLA)—the update introduces machine options for SafeMOTION parameters and improves both system availability and user-friendliness. To obtain a safe, absolute multi-turn position, homing used to be necessary each…

Humans and robots, hand in hand

With the fourth industrial revolution, the complexity of production processes is growing rapidly. In an effort to adapt to these new challenges, food and beverage companies are increasingly turning to automation technology. In addition, safety is always an issue when robots and humans work in the same area. The SafeROBOTICS functions offered by B&R Automation…

Revamped servomotors from B&R more powerful

Revamped 8LS series servomotors from B&R are now more powerful than ever. A more compact housing, optimized design and additional sizes are other improvements. Size 2 and 3 servomotors…