By 2028, the 40-plus electric vehicle (EV) battery-manufacturing sites in the U.S. could annually output product capable of 1,037 GWh … tracking to increase by twentyfold from the size of the industry just a few years ago, according to the U.S. Dept. of Energy. One geographical corridor running from Michigan to Alabama currently dominates the industry,…

Festo’s new palletizing gantry lifts up to 440 lb

Festo introduced a heavy-duty Cartesian gantry for palletizing with a lift capacity of up to 440 lb, Z-axis stroke lengths exceeding 8 ft, and a speed of up to 5 ft/s. With free online design tools, off-the-shelf servo drives, motors, and other components, and quick assembly kits, this Festo palletizing solution shortens project time and…

Integrated linear-motion variations becoming the norm

Automation over the last several years has expanded use of electric linear actuators to leverage their technological advancements in smart homes, aerospace, defense, and industrial applications. In fact, the global linear actuator market could (in large part because of electric options) surpass U.S. $52.67B this year and grow at a compound annual growth rate through […]

Driving change in packaging automation

Many trends in general automation have impacted the packaging industry. Some of these include the multiple benefits of better efficiency and increased speed and accuracy of automation systems in general, leading to improved packaging machinery. At the same time, there is more concern with sustainable practices and design, which means more emphasis on biodegradable materials […]

Trends in artificial intelligence for 2024

According to Gartner’s research, up to 25% of organizations surveyed annually since 2019 said they plan to leverage artificial intelligence (AI) within the next 12 months. However, only up to 5% have deployed AI to production. Companies know that generative AI can dramatically improve operations, but inexperience and potential risks postpone the benefits. Predictive maintenance,…

Advances beget advances in laboratory automation

According to Global Market Insights, laboratory automation’s market size was 6.7 billion (USD) in 2023. The site also reported an expected CAGR of over 6.7% between 2024 and 2032. What’s expected to account for this growth? What specific trends will act as the catalyst for bringing the laboratory automation sector into the double-digit billions? We…

Trends: Drives and controls incorporate more safety and feedback

The last decade has seen advancements in controls and motor drive technologies to boost efficiency, safety, and ease of use. Now commonplace are drives that: Let end users leverage autotuning functions for faster commissioning Detect and correct for vibration issues — including the shaping of power into motors to avoid resonances Spur increasingly compact motors…

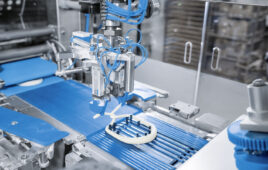

Festo Power Up initiative aims to transform machine building for food and beverage

The Festo Power Up initiative for food and beverage machine builders aims to spur the efficient adoption of electric automation and in the process support the development of the next generation of compact, flexible, energy efficient, and data-rich machines. Three pillars support the initiative. Machine builders now have the option of a Festo one-stop-shop of […]

Festo introduces an online 3D CAD configurator

Festo continues to enable original equipment manufacturers (OEMs) to lower engineering and purchasing overhead and bring machines to market faster with the company’s new online 3D CAD Configurator for pneumatic actuators and associated accessories such as fittings, lengths of tubing, and sensors. The tool is intuitive and easy to use. Once the actuator is selected…

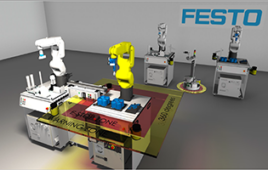

Festo: The right handling system in just 20 minutes

The Handling Guide Online is revolutionizing engineering for ready-to-install solutions As of immediately, technicians and engineers arrive at the right ready-to-install handling system at a record-breaking tempo in the areas of project engineering and planning. They can now order new system solutions intelligently and intuitively via the new Festo Handling Guide Online – without any…

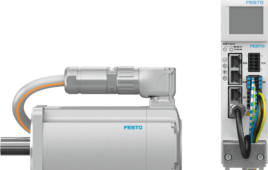

New Festo family of multi-protocol servo drives

Festo introduces the CMMT MP family of multi-protocol servo drives. Every drive in this family is configurable as EtherNet/IP, EtherCAT, PROFINET, and Modbus TCP. Using this single-family multi-protocol strategy, machine builders supporting multiple communications protocols can reduce servo-drive inventories. A unified drive family improves engineering productivity through familiarity with a single platform, simplifies tech support,…

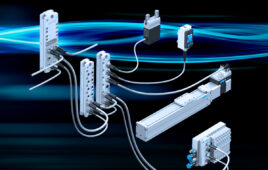

Festo Electric and Pneumatic Motion reaches a pinnacle in North America

With the recent introduction of its distributed I/O solution CPX-AP-A, along with its established CPX-AP-I decentralized I/O, Festo now offers a range of electric and pneumatic automation solutions that is unmatched in North America in terms of performance, flexibility, cost savings, and engineering productivity. AP stands for Automation Platform and this backplane-based remote I/O system…

The new Festo solution for DeltaV DCS expands integration options and productivity

Festo now offers CPX valve manifold configuration to Emerson DeltaV DCS systems for fast, simple, and effective programming, commissioning, and validation of Festo-based pneumatics for skids and machines. This first-of-its-kind third-party commissioning solution brings one of the world’s most versatile valve manifold control platforms, CPX, to the DeltaV DCS ecosystem. Fast commissioning enables system integrators…

Top trends in linear motion technology: Part 2 of 2

For the annual Design World Trends issue, we asked industry experts to share their insights into linear-motion trends. Here’s more of what they had to say on linear actuators, linear guides, and stages. Meet the experts Dave Walden | Applications engineer • PBC Linear Eric Rice | Product market manager — electric automation • Festo Samuel Orozco | […]

Top trends in linear motion technology: Part 1 of 2

We recently asked several industry experts about trends they’re seeing in the design and use of linear actuators, linear guides, and stages. Here’s what those experts had to say. Meet the experts Saurabh Khetan | Product line manager — Leadscrews • Thomson Industries Inc. Justin Lackey | Product manager — Systems • Bosch Rexroth Kelly Walden | V.P. […]

How design support and e-learning are addressing labor shortage

We recently asked several industry experts about trends they’re seeing in engineering training, software tools, and support. Here’s what those experts had to say. Meet the experts Nathan Andaya | Director Techline SBU • LINAK U.S. Boaz Eidelberg | CTO • SAAR Inc. James Gallant | Director of operations • ISL Products International Ltd. Chris…

The latest in EV, eBike, and AGV motion systems

We recently asked several industry experts about the trends they’re seeing in the design and use of electric vehicles (EVs), scooters, eBikes, and autonomous ground vehicles (AGVs). Here’s what those experts had to say. MEET THE EXPERTS Ian Blasch | Senior director— business development • Jabil James Gallant | Director of operations • ISL Products…

Top industrial connectivity and digital-transformation trends: Part 2 of 2

In the first part of this Design World Trends series, we heard from industry experts about discrete automation’s edge devices; efforts to promote standards for increased system compatibilities and interoperabilities; and the rise of fog computing as well as industrial uses for wireless technologies such as 5G. In this follow-up piece, we detail the holistic…

Top industrial connectivity and digital-transformation trends: Part 1 of 2

Discrete automation’s edge devices include actuators, sensors, and connectivity components such as gateways and motor-mounted controllers. Many of these components feature computational capabilities to minimize data bandwidth and latency issues associated with legacy versions of centralized control. Their installation at the furthest reaches of automated equipment means their processing power is situated to filter and…

Hannover Fair preview: Festo’s PhotoBionicCell and its automated cultivation of biomass

Algae are small climate savers. Even in their natural state they are extremely efficient photosynthesizers and absorb ten times more carbon dioxide (CO₂) than land plants. In bioreactors equipped with appropriate sensors, control technology and automation, the efficiency of algae can be increased to a hundred times that of land plants. This shows that they…

New Festo AI Solution improves machine usage, product quality, and energy efficiency

Festo introduces the Festo Automation Experience (AX), a new artificial intelligence (AI) platform for predictive maintenance, predictive quality, and energy optimization. Using advanced analytics, Festo AX maps data to learn a component, machine, product, or energy system’s healthy state. Festo AX provides actionable information to correct anomalies when data begins trending out of normal. At…

Festo introduces at Pack Expo AI for improved uptime, quality, and energy efficiency

Festo Automation Experience (AX), a new artificial intelligence (AI) platform for predictive quality, predictive maintenance, and energy optimization. Using advanced analytics, Festo AX maps data to learn a component, machine, product, or energy system’s healthy state. Festo AX provides actionable information to correct anomalies when data begins trending out of normal. Festo demonstrates AX at…

Festo wins coveted 2022 LEAP Award

Festo took home a silver medal in the recently completed 2022 Leap Awards. The LEAP Awards celebrates the most innovative and forward-thinking products serving the design engineering space. Festo won in the Sensors and Switches category covering equipment feedback devices such as mechanical switches and photoelectric, proximity, reel, and hall-effect sensors. Submissions also included devices […]

Festo Didactic and SICK release new curriculum for robot safety awareness: we got you covered.

Smart Technology is rapidly evolving, especially in the automation and engineering space. This can make it difficult for professionals and aspiring engineers to be adequately prepared throughout their careers. Festo Didactic, equipment and solution provider for industrial and technical education, developed the program to holistically teach students robot safety. Students can learn the latest industry…

Festo introduces smart positioner for process valve control

Festo has reimagined pneumatic process valve position control through the new CMSH smart positioner and VTOP modular installation platform. The CMSH contains a host of features, including HART communications protocol and integrated safety functions that can provide customers with up to 30% in savings. The attach-and-play VTOP ‒ with any combination of filter regulator, booster,…