EP42HT-2FG Black is a two-part, moderate heat-cured epoxy with high-temperature resistance that complies with FDA 21 CFR 175.105 for indirect food contact applications. The epoxy withstands exposure to a wide range of harsh chemicals, including acids, bases, and solvents. It possesses good flow properties and can be employed for bonding, sealing, potting, and casting. This…

Medical grade epoxy offers thermal conductivity and electrical insulation

Master Bond EP42HT-4AOMed Black is a new two-part epoxy created for medical device manufacturing. It is biocompatible and non-cytotoxic, passing both USP Class VI and ISO 10993-5 certifications. This epoxy withstands aggressive chemical sterilants, radiation, and repeated cycles of autoclaving. EP42HT-4AOMed Black offers both cryogenic serviceability and heat resistance with a service temperature range from…

Toughened epoxy polysulfide hybrid offers advanced chemical resistance

Master Bond EP21TP-2NV is a two part epoxy polysulfide formulated for use as an adhesive, sealant and potting system. It withstands prolonged exposure to many harsh chemicals including fuels, oils, hydrocarbons, and hydraulic fluids. It is also fully RoHS compliant, meeting RoHS3 Directive (EU) 2015/863. EP21TP-2NV offers an elongation between 40-80% at room temperature and…

Silver conductive, one-component epoxy cures at 80°C

Master Bond Supreme 3HTS-80 is a one part, silver filled epoxy adhesive that is not premixed and frozen and features an unlimited working life at room temperature. “While typical heat activated epoxies require 250°F to 350°F to cure, Supreme 3HTS-80 cures at 175°F to 185°F within 2-3 hours” says Rohit Ramnath, Senior Product Engineer. “Curing…

Glob top epoxy meets NASA low outgassing specifications

Master Bond EP17HTND-CCM is a new single component epoxy that is not premixed and frozen. It is more convenient to handle, apply and store than typical two component glob top systems. This black, heat curable compound has a flowable paste consistency suitable for glob top, chip coating and bonding applications. EP17HTND-CCM meets NASA low outgassing…

Removability and optical clarity from MasterSil 170 gel encapsulant

Master Bond MasterSil 170 Gel is a two-component system with excellent flowability for potting and encapsulation applications. It possesses a low mixed viscosity of 1,000 cps, has a long working life after mixing (2-4 hours for 100 g batch), a low exotherm upon cure and is easy to dispense. This solvent-free silicone product does not…

Epoxy-based, dual curing adhesive

Master Bond UV22DC80-10F is a single component, nanosilica filled compound featuring a UV and heat curing mechanism. This thixotropic, moderately low viscosity compound has a viscosity of 8,000-12,000 cps at 75°F (~ 23°C). It provides outstanding dimensional stability and physical strength properties. Additionally, UV22DC80-10F is optically clear and offers the ability to be cured in…

Special adhesives bring clarity to optic applications

Fiber optic, opto-electronic and photonic applications must have superior transparency, requiring optically clear epoxies, polysulfides, and silicones that exhibit excellent light transmission. Contributed by Rohit Ramnath, Senior Product Engineer, Master Bond Optical transmission, the ability for light to be channeled through a material, is particularly important for fiber optic, opto-electronic and photonic applications. As a…

Thermally Conductive, Electrically Insulative Epoxy Delivers Low Exotherm for Large Castings and Potting Applications

Master Bond EP39MAOHT is a room temperature curing system for demanding bonding, sealing, coating, potting and encapsulation applications. “It is a versatile product that combines convenient handing, good flow, thermal conductivity, electrical insulation and high temperature resistance,” said Robert Michaels, vice president of technical support. “Its toughness lessens the chance of stress cracking when thermally…

One Part, Toughened Epoxy for Specialty Dam-and-Fill Encapsulation

Master Bond Supreme 3HTND-2DM is a rapid curing, toughened, one part epoxy system used for the dam-and-fill method for chip-on-board encapsulation. Essentially, there are two methods to protect chips and their wire bonds. One method is referred to as glob top, where the encapsulating system is dispensed and applied directly to the area to be…

Room Temperature Curing Epoxy Features Low Thermal Resistance

Formulated for use in demanding thermal management applications, Master Bond EP30TC is a two component epoxy that contains a robust thermally conductive filler with very fine particle sizes. This NASA low outgassing certified system can be used for bonding, coating, sealing and encapsulating for the aerospace, electronic, optical and OEM industries. EP30TC exhibits a thermal…

Non-Drip, Medical Grade Epoxy Resists Repeated Sterilizations

Master Bond EP3HTND-2Med Black is a high strength, fast curing epoxy for use in the assembly of medical devices. It fully meets USP Class VI specifications. This one part system delivers superior resistance to a variety of sterilization methods such as chemical sterilants, EtO, radiation and especially autoclaving. As a one component system, EP3HTND-2Med Black…

Electrically and Thermally Conductive, Two Part Silicone Meets NASA Low Outgassing Specifications

Well suited for use in vacuum environments, Master Bond MasterSil 973S-LO is an adhesive, sealant and coating that passes NASA low outgassing tests. This electrically conductive, two component silicone can be used in the aerospace, electronic, opto-electronic and specialty OEM industries. Featuring a low volume resistivity of 0.004 ohm-cm, MasterSil 973S-LO is a silver filled…

No Mix, thermally conductive, electrically insulative Epoxy for underfill applications

Master Bond EP3UF is a one component epoxy that contains thermally conductive fillers with very small particle sizes imparting a low thermal resistance of 5-7 x 10-6 K•m2/W. This low viscosity system has good flow properties and can be applied in bond lines as thin as 10-15 microns. It offers a thermal conductivity of 9-10…

Electrically conductive epoxy meets NASA low outgassing specifications

Master Bond EP3HTS-LO is a single component epoxy for demanding bonding, sealing and coating applications. This system passes ASTM E595 tests for NASA low outgassing, making it well suited for use in the aerospace, electronic, microelectronic and optical industries. Featuring a silver filler, EP3HTS-LO is electrically conductive with a low volume resistivity of less than…

Two component strengthened epoxy offers chemical, abrasion and high temperature resistance

Featuring a silicon carbide filler, Master Bond Supreme 45HTQ-4 is a toughened epoxy for high performance bonding, sealing, coating and casting. This specialty system can be used for a wide variety of special industrial, aerospace, OEM and oil processing applications, especially in downhole situations. Supreme 45HTQ-4 has the unique combination of exceptional chemical, temperature and…

Non-yellowing UV curable system has superior abrasion resistance

Master Bond UV15X-6NM-2 is a one component UV curing urethane acrylate system formulated for a variety of bonding, sealing, coating and encapsulation applications. This moderate viscosity product features flexibility, toughness and abrasion resistance. It is widely used for fiber-optic, optical, electronic, semiconductor, microelectronic and laser applications. UV15X-6NM-2 features an elongation exceeding 200%, which contributes to…

Thermally conductive, electrically insulative two part silicone meets NASA low outgassing specifications

Master Bond MasterSil 972TC-LO passes the rigorous requirements for low outgassing per ASTM E595 specifications. It is particularly well suited for use in vacuum environments as well as applications in the aerospace, electronic, opto-electronic and specialty OEM industries. This two part silicone system offers convenient handling for bonding, sealing, coating and potting. MasterSil 972TC-LO is…

One component dual cure epoxy meets USP Class VI and ISO 10993-5 specifications

Master Bond UV15DC80Med offers a unique dual curing mechanism which employs UV light followed by heat to complete the polymerization. This allows for curing areas on parts that do not allow UV light curing because of “shadowing” issues. This kind of UV system is highly desirable because it allows for rapid fixturing with completion of…

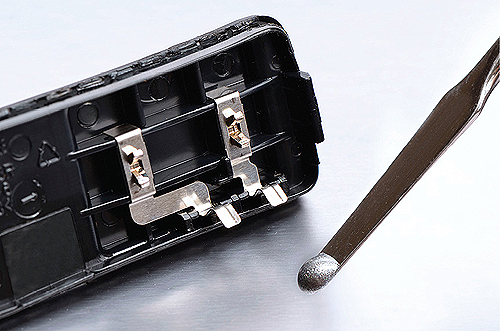

Protect circuitry from EM/RFI and ESD with conductive coatings

by Rohit Ramnath, Master Bond Inc. Electrostatic charge discharged through an IC can damage the IC. But protective coatings can deliver needed static protection without adding physical components that do not have any other purpose beyond ESD protection on the chip. Electromagnetic interference (EMI) and radio frequency interference (RFI, so called because the offending source…

New Catalog on Adhesives, Sealants and Coatings

Master Bond is offering a new, easy to read, 28 page catalog with performance and processing data on its extensive line of epoxies, silicones, UV curing compounds and specialty systems for the aerospace industry. These products ensure reliability in the assembly of aircraft structures, components, interiors and MRO applications. They are widely used for structural…

One Component, Aqueous Based Coating System

Well suited for electromagnetic interference and radio frequency interference shielding applications, Master Bond MB600G is an aqueous based, sodium silicate system with graphite filler. Graphite filled materials are widely used for shielding and static dissipation applications because of the balance of shielding effectiveness and cost. Shielding effectiveness is most often measured by attenuation. It is…

Optically Clear, Condensation Curing Silicone

Developed for potting and encapsulation applications where an addition cured silicone cannot be used, Master Bond MasterSil 152 is a two component, condensation curing system that only requires air for complete cross-linking. Unlike addition cured systems, there are no substrates that will inhibit the cure. This system fully cures at room temperature in 24-48 hours…

Thermally Conductive Epoxy Resists High Temperatures

Formulated for bonding and sealing applications, Master Bond EP46HT-1AO is widely used in the aerospace, electronic and specialty OEM industries. Unlike most conventional two component epoxies, EP46HT-1AO cures with the addition of heat, which allows it to have a working life exceeding 24 hours. It has a forgiving 100 to 30 mix ratio by weight…

Epoxies: The “Go To” Materials for Oil and Gas Instrumentation

By Robert Michaels, Vice President Technical Sales, Master Bond Oil and gas are a primary source of energy. In the exploration and extraction of oil and gas, epoxies can be found in most of the equipment used to search, assess, and extract these sources of energy. In the last 200 years or so, oil and…