Nook Industries, a linear motion manufacturer, has formally announced the separation of its former subsidiary, Helix Linear Technologies. Nook and Helix operate as independent entities. “Nook Industries continues to focus on exceeding the expectations of our customers, by offering exceptional engineering and quality products in our competitive market,” said Joseph Nook III, CEO at Nook.…

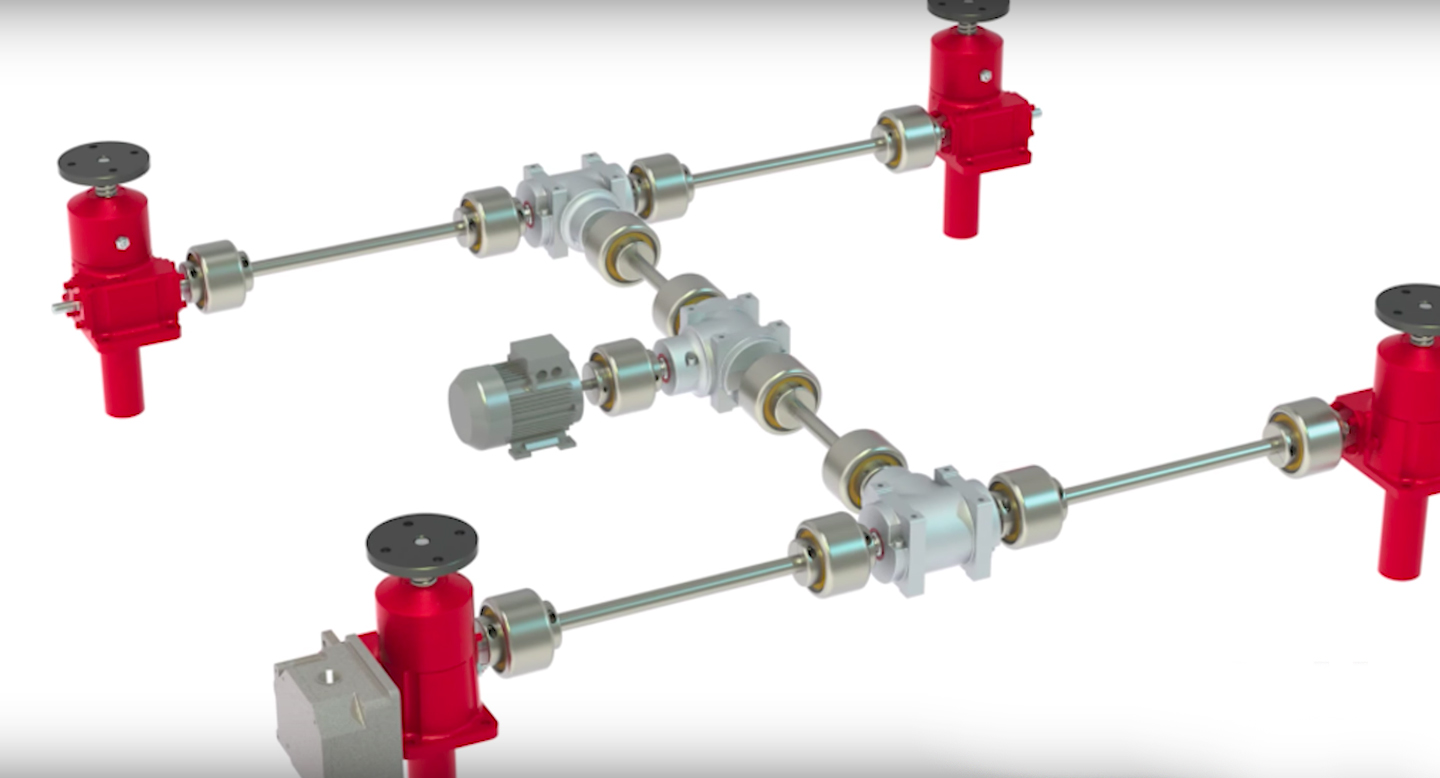

Linear actuator designs for vertical lifts: What are pitfalls to avoid during jack-system design?

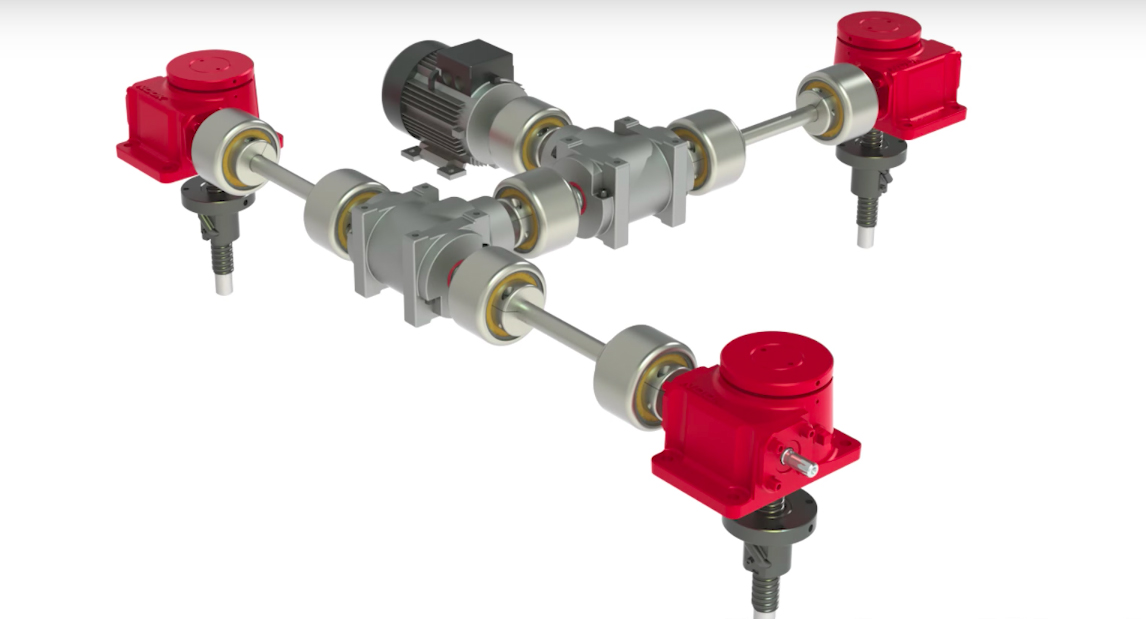

A jack system is anything from a single jack to eight to ten jacks working in tandem to move a load. Complete jack systems refer to the mechanical components of the jacks as well as their gearboxes and couplings and accessories and shafting; electrical components including motors, the system drive, and encoders; and the motion […]

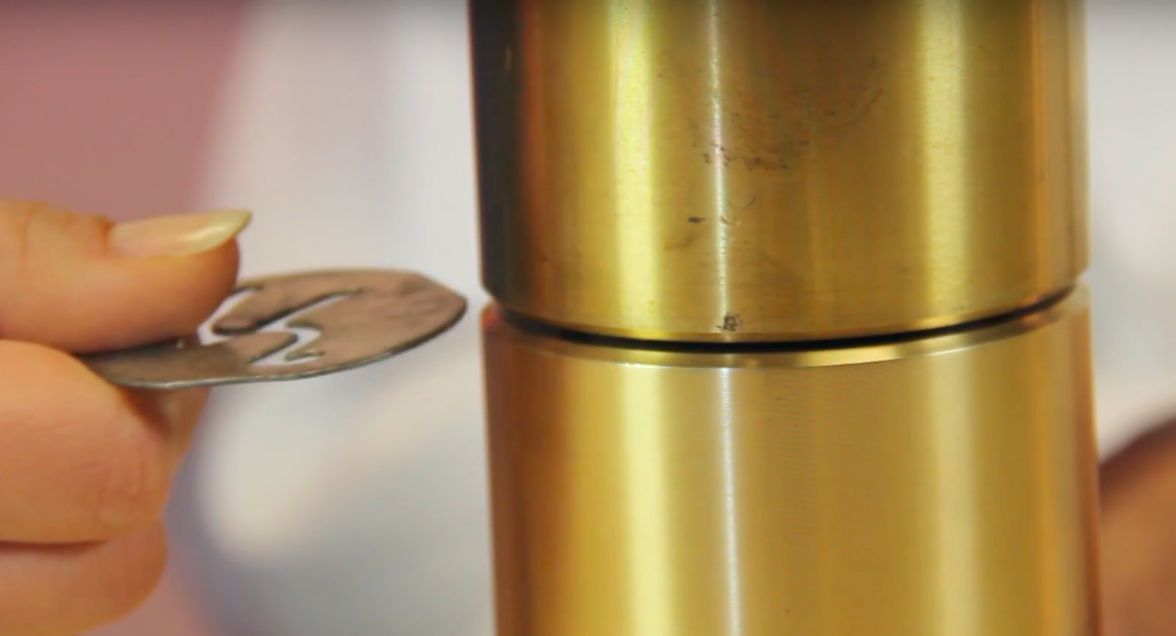

Wear indicator nuts for jacks: How do they work?

One concern when designing a lift platform based on screw jacks is how to know if the travel nut (which bears the load) is worn out or about to fail — especially when the lift operates in a place where personnel might get hurt if the mechanism fails. In these machines, a follower nut assembly […]

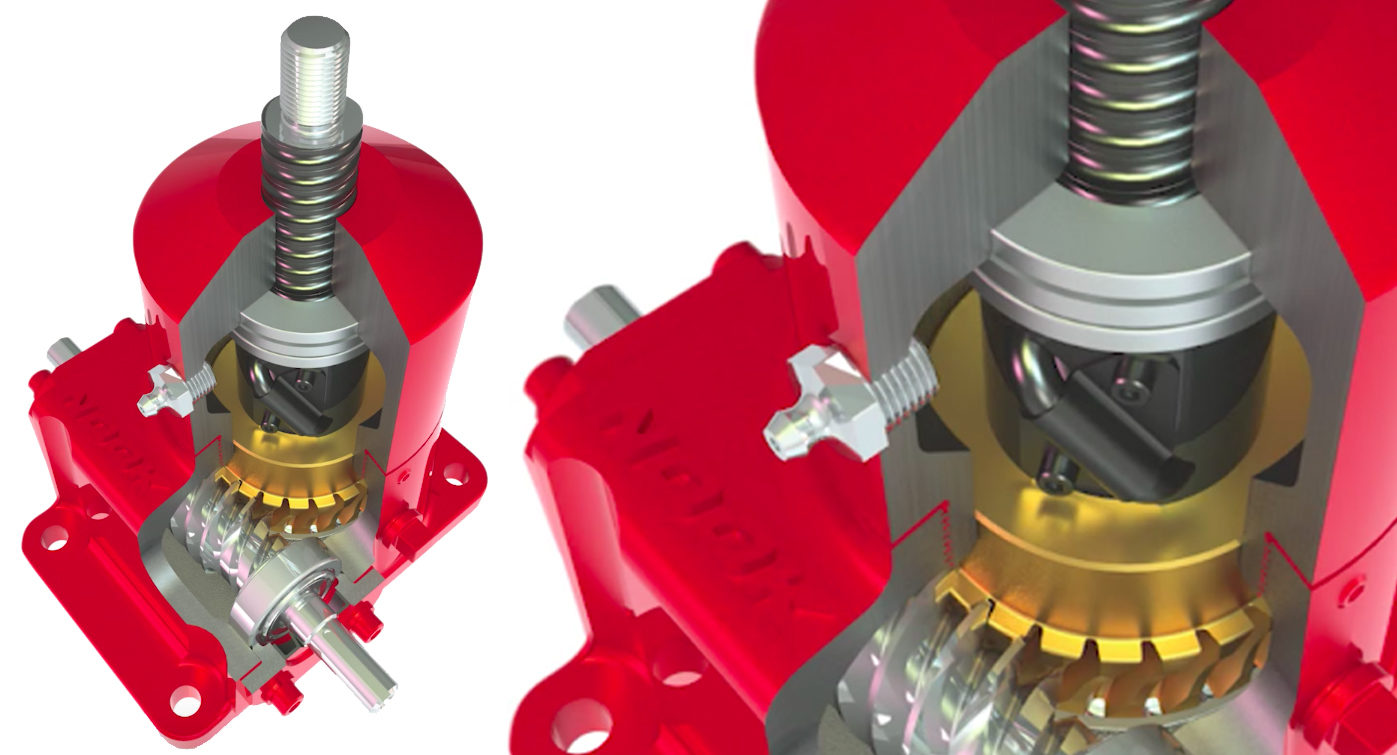

What are the six basic parts of a worm-gear jack for vertical motion applications?

Screw jacks are indispensable linear-motion designs for lifts and other vertical-motion applications. They consist of six main components. First there is the housing. This contains all of the internal jack components. Second is the worm shaft – this is an input to the jack and typically where a motor handwheel is attached. The third jack […]

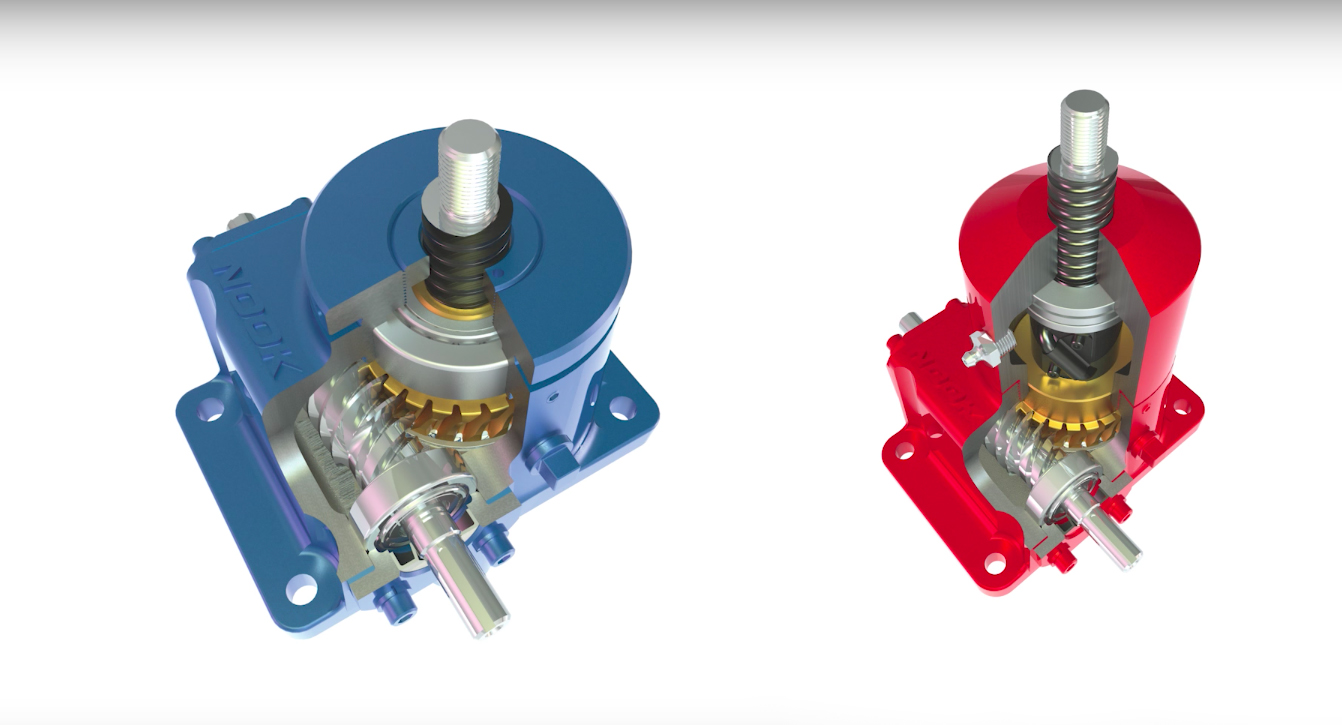

What’s the difference between ball screw jacks and machine screw jacks?

Most prevalent are worm gear screw jacks because they can lift heavy loads with little input torque. The large mechanical advantage is through a worm gear ranging from 5:1 to 32:1 in combinations with lead screw or a ball screw. Ball screw jacks differ from machine screw jacks in a few key ways. Machine screw […]

When is a worm-screw jack the best linear motion solution for a vertical application?

Worm-screw jacks are a linear-motion design that’s been around for decades — though the modern version of the screw jack has changed a lot since its inception in the 1940s. Today’s versions use a basic worm-gear mechanism to drive either an acme screw or ball screw. When is a worm-screw jack a suitable linear-motion solution? […]

How to calculate ball screw rigidity

The rigidity of a ball screw determines the amount of elastic deformation it will experience in the axial direction, under a given load. Elastic deformation, and therefore rigidity, is a…

![]()

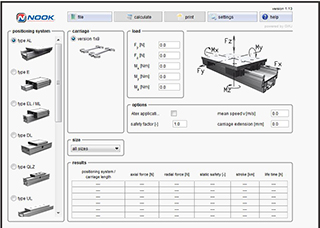

Nook Industries Introduces Modular Actuator Calculator

Nook Industries, a leading innovator of linear motion components and systems, has introduced an engineering calculator for modular actuators—one of the only of its kind in existence. The…

![]()

Nook Industries offers complete line of worm gear screw jacks

Nook Industries, a leading innovator of linear motion components and systems, offers the ActionJac™ series worm gear screw jack product line. ActionJac models are ruggedly designed and produced in…

![]()

Ball screw lubricant from Nook Industries

Nook Industries, a leading innovator of linear motion components and systems, offers E-900 ball screw lubricant for use on any of its ball screw products, such as ball screw…

![]()

Standard ball screws now available from Nook Industries

Nook Industries, a leading innovator of linear motion components and systems, proudly offers a complete line of standard ball screw products. An upgrade from acme screws, ball screws…

![]()

Caged ball profile rails for linear guidance

Nook Industries introduces a caged ball profile rail for linear guidance. Caged ball chains provide reduced friction, lower noise levels and prevent the bearings from making incidental contact. Nook’s…

![]()

Bevel gear screw jack system for variety of specifications and duty cycles.

Nook Industries’ line of bevel gear screw jack systems, under the ActionJac brand, is available in many configurations. Available in machine and ball models, all bevel gear screw…

Nook Industries offers caged ball profiled rails for linear guidance

Nook Industries, a leading innovator of linear motion components and systems, introduces caged ball profile rails for linear guidance. Caged ball chains provide reduced friction and lower noise…

What happens when you combine a planetary gear with a ball screw?

Answer: You get a planetary roller screw. Replacing the recirculating balls of a ball screw with grooved rollers results in a precision drive mechanism with extremely high load capacity,…

Miniature linear ball rails from Nook Industries for high-speed running capacity

Nook Industries, a leading innovator of linear motion components and systems, has launched a new miniature linear ball rail ideally suited for high-speed, belt-driven mechanisms and carrier designs…

Nook Industries offers complete line of Series 500™ Programmable Actuators

Nook Industries offers a complete line of Series 500 programmable actuators designed for continuous duty and long service life. The Series 500 incorporates a direct or toothed-belt drive…

New line of stepper motors from Nook Industries

Nook Industries has introduced a line of new stepper motors designed to provide a total, single source for linear motion solutions. The new line can power ball screws,…