This webinar was recorded on November 3, 2015. Fill out the form below to watch on demand. Why aluminum extrusions provide automotive OEMs the total solution when it comes to weight, cost, quality and—most importantly—thermal management. Driven by the need to improve fuel economy and reduce carbon emissions, the automotive industry has focused on developing Electric-drive…

Work with stronger joints and lighter materials

by Mary C. Gannon, Senior Editor Enable consistent, strong and more efficient structures with friction stir welding. Traditionally, joining two separate pieces of metal requires a filler material, usually an alloy different from the base metal. For example, MIG and TIG welding is most common in the aluminum extrusion industry, but in some cases, adding…

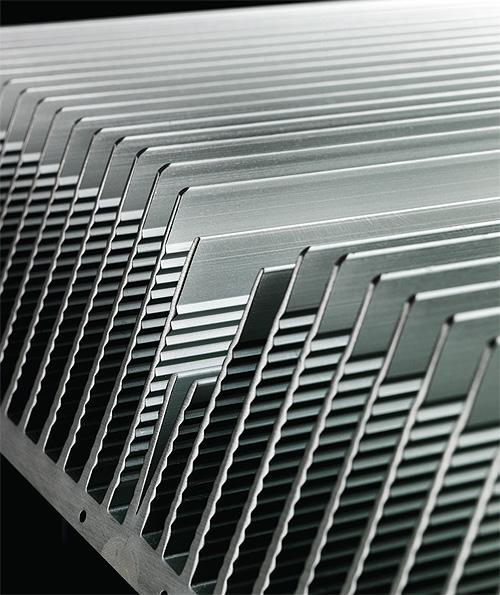

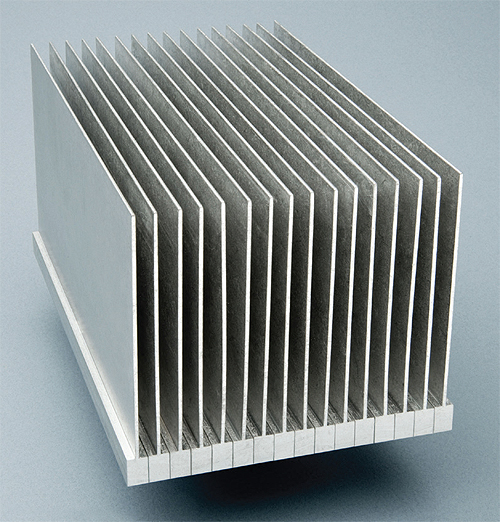

Creating large heat sinks

By Stephen Jackson, Business Development Manager of Thermal Managemenet, Sapa Extrusions North America A recent innovation in aluminum extrusion offers a new way to produce higher ratio air-cooled heat sinks — heat sink ratios in excess of 40:1, and widths up to 30 in. Aluminum extrusion at its most basic is the process of pressing…

Friction Stir Welding: Consistently Enabling Stronger, More Efficient Structures

This webinar will demonstrate Friction Stir Welding (FSW) as an alternative to other welding and mechanical joining methods of extruded aluminum profiles. Until recently, FSW has been mostly used in aerospace structures. However, as the FSW technology became more widely known end use applications have grown. Today, one can fine FSW welded structures in many…

Aluminum Extrusion Design And The Role It Plays In High Performance Cooling Solutions

As power densities continue to increase, so does the demand for an efficient means of cooling electronics in a cost effective manner. This is leading to a transition from basic heat sinks to high performance heat sinks. Whether that means maximizing surface area or taking the next step to liquid cooling, much of this demand…