Machine tool builders often find themselves with the problem of interfacing servo motors with specially tapered conical shafts into their mechanical assemblies. The unique geometry characteristic of many CNC motor shafts normally requires that custom mounting flanges be designed and ordered to allow for the motor to mount to their machine. Many go without a flexible coupling at all, placing high levels of undesired stress on shaft bearings when the motor frame is bolted down.

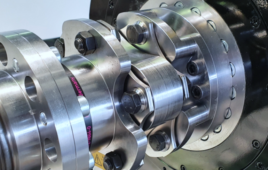

The BK4 bellows coupling was designed to address this problem. Utilizing a stainless steel bellows, the couplings can compensate for slight misalignments in motor mounting with zero backlash and a high level of torsional stiffness. With the tapered bore machined directly into the coupling’s hub, users save space as well as the time it would take to design their own adapter.

The output of the coupling is configured with a removable clamping bushing in order to allow access to the inner face of the tapered bore for tightening onto the tapered shaft. This clamping bushing can be bored to whatever English or metric shaft diameter the customer requires. Many sizes are off the shelf, and many more are available upon request.

: Design World :

Filed Under: Couplings

Tell Us What You Think!