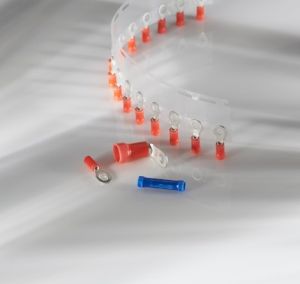

PLASTI-GRIP terminals and splices are pre-insulated RBY terminals and splices designed specifically to answer the need for inexpensive, insulated electrical terminations. The quality, ease of installation and inherent simplicity make them candidates for almost all commercial applications. PLASTI-GRIP is available in ring, spade, flanged, spaded, and slotted tongue terminals, as well as parallel and butt splices.

PLASTI-GRIP terminals and splices consist of a high conductivity copper body and color-coded PVC insulation that can be used in  almost all commercial applications. The wire and terminal barrel provide a connection of maximum conductivity, tensile strength, and high resistance to corrosion. The terminations are tin plated and accept a wire range of 26 AWG – 2/0AWG (0.12 – 76 mm2). Operating voltage is 600 V, temperature rating is 105°C max. The terminations are UL listed and CSA certified.

almost all commercial applications. The wire and terminal barrel provide a connection of maximum conductivity, tensile strength, and high resistance to corrosion. The terminations are tin plated and accept a wire range of 26 AWG – 2/0AWG (0.12 – 76 mm2). Operating voltage is 600 V, temperature rating is 105°C max. The terminations are UL listed and CSA certified.

These terminals and splices are well accepted in all markets and feature easy installation with TE tooling, crimp-performance guaranteed. The insulation provides good dielectric strength and supports the wire insulation so that no bare wire is exposed.

Funneled wire entry on the terminal prevents turned-back wire strands and permits rapid wire insertion during high speed production. Serrations in the crimp barrel provide maximum contact and tensile strength after crimping. The “C” crimp is specially designed by TE for a long-lasting crimp.

Application tooling has been developed to ensure uniform high-quality terminations. Tools and terminals have been designed together to promote ease and speed of application while providing precise crimping pressure for every wire size. PLASTI-GRIP is available in ring, spade, flanged, spaded, and slotted tongue terminals, as well as parallel and butt splices.

Applications include HVAC, instruments/controls, lighting, switchgear, power supplies, panel boxes, transportation, motors, and many more.

TEConnectivity, 1050 Westlakes Drive, Berwyn, PA 19312, 610 893 9800, 800 522 6752, www.te.com.

You may also like:

Filed Under: Cables + cable management, Connectors (electrical) • crimp technologies