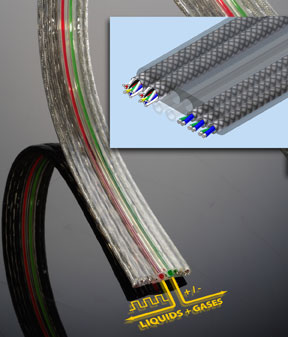

Valencia, CA — CICOIL, the leading manufacturer of flat, flexible cabling, announces the immediate availability of integrated Teflon® hollow tubing for their flat power and signal cables.

Cicoil President Howard Lind states, “Adding tubing as an integral part of our flat cables helps designers simplify their equipment. If fluids or pneumatics are needed, these can now be integrated with electrical wiring in one compact cable, versus requiring multiple cables, tubes and wires. Combining everything into one cable results in a cleaner, more compact design, which ultimately is more reliable and cost-effective.”

The new tubing option is suitable for pneumatics or fluids, making it an ideal addition for many motion applications that normally require additional conduits for those elements. Applications include medical diagnostic equipment, wafer-handling robots, painting robots, and automated pick-and-place equipment. Teflon® tubing can be used with most liquids and gases, and like Cicoil’s silicone cables, it operates reliably in temperature extremes from -65°C to +260°C. The Teflon® tubing is available in a wide variety of standard English and metric sizes.

The tubing option may be included in any custom cable and is also available as a standard option on the company's Motion Series Plus high flex cables for high performance motion control.

Cicoil has been a leader in designing and manufacturing high performance cable assemblies for over fifty years. The company's unique silicon coated flat cables provide high flexibility, extremely long life, and they can withstand temperature extremes from -65 degrees to +260 degrees Celsius. Cicoil's cables are used in thousands of demanding applications, including aircraft fuel control cells, semiconductor automation, and the Space Shuttle. Cicoil designs and manufactures its cable and cable assemblies in an automated facility in Valencia, California. Cicoil's quality assurance system is certified to the ISO 9001 (AS9100) standard.

Visit www.cicoil.com for more information, or call 661-295-1295 to speak to an application engineer.

.: Design World :.

Filed Under: Cables + cable management, ELECTRONICS • ELECTRICAL

Tell Us What You Think!