This webinar was recorded on November 3, 2015. Fill out the form below to watch on demand.

This webinar was recorded on November 3, 2015. Fill out the form below to watch on demand.

Why aluminum extrusions provide automotive OEMs the total solution when it comes to weight, cost, quality and—most importantly—thermal management.

Driven by the need to improve fuel economy and reduce carbon emissions, the automotive industry has focused on developing Electric-drive vehicles (EDVs) as well as the lightweighting of vehicles. This increasing trend has been supported by major manufacturers such as Ford and Tesla. However, with any change in technology new challenges develop. Thermal Management of these vehicles is a large challenge, along with the need to structurally hold the components in place.

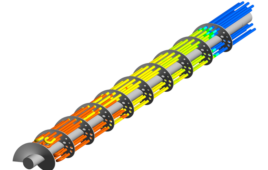

Aluminum’s characteristics make it an ideal candidate to replace heavier materials in vehicles while addressing the additional thermal management requirements. These characteristics include: high thermal efficiency, high strength to weight ratio; it can be machined, formed and welded, it is non-sparking so it can be used near flammable substances and resists corrosion. Additionally, with new Friction Stir Welding technology, it can be used to manufacture low cost wide extrusions and liquid coolers that can withstand pressures up to 2,700 psi.

Attend this webinar to learn:

- How aluminum extrusions provide a structural and thermal management solution to vehicles where weight is a concern

- How extrusions are being used to solve thermal management and battery enclosure challenges in Electric-drive vehicles (EDVs)

- How extruded cold plates are replacing cast cold plates to provide a more economic, thermally efficient, and lighter solution

- How Friction Stir Welding (FSW) can be used to manufacture extrusions wider than any extrusion press in the world

Featured Speakers:

Jason Weber is the Director of Business Development for Energy and Industrial Products at Sapa Extrusions North America. He holds a Bachelor of Science degree in Business Administration and Marketing from Minot State University in North Dakota.

Steve Jackson is the Business Development Manager of Thermal Management at Sapa Extrusions North America. He holds a B.S. in Mechanical Engineering, Materials Science from WPI and has worked in the thermal management industry for more than 20 years.

Brought to you by:

Filed Under: WEBINARS

Tell Us What You Think!