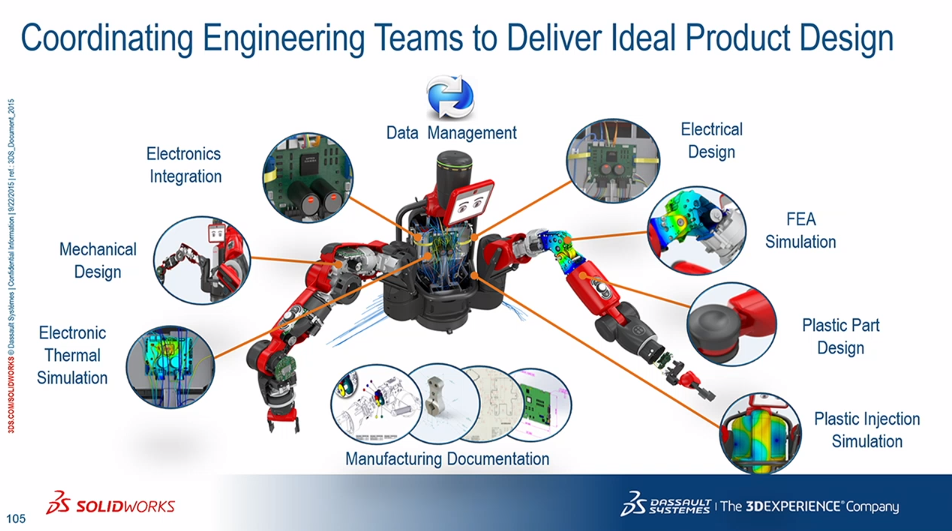

Designing smart, connected products requires a carefully-coordinated interdisciplinary effort. Image Credit: SolidWorks

From wearables and drones to cars, home appliances and medical equipments, the world is increasingly progressing towards a connected era. Gartner predicts that the number of connected devices is set to touch 25 billion by 2020 and will contribute an estimated $3 trillion to the economy. This new economy of goods and services based around Web, Analytics and Apps is opening new opportunities for manufacturing companies to develop connected products and gain advantage of this unprecedented IoT trend.

The infrastructure and skills required are available and companies now need to adapt to this trend to develop smart products for smart consumers. This change is happening; 1 in 5 mid-range companies worldwide have begun IoT initiatives according to the research report titled “Lessons learned from early adopters of IoT” by Machina Research. Interestingly, companies leading the charge are from product development background rather than those involved in Information Technology.

About 80% of these early adopters have done the entire product development themselves in a pursuit to bring the idea faster to the market; but in this journey they have underestimated the complexity of IoT, leading them to focus less on the product lifecycle.

The Machina Research shows that almost 60% of future adopters of IoT are as such looking to partner with industry leaders to keep their development process seamless and less complex. The reason why the process of developing a connected product is complex is mainly because of the involvement of multiple disciplines and engineering teams to deliver ideal product design.

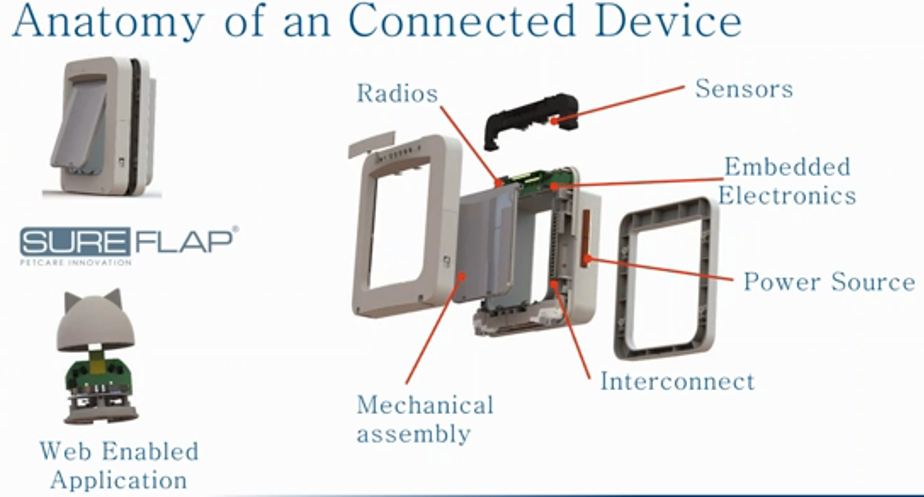

The Anatomy of a Connected Product

Unlike conventional product, a connected product requires engineering expertise that spans across mechanical, electrical and software systems. Web and App are two entities that fuse together with the product to make it connected. As such, for product manufacturers, this is almost like an alien technology requiring multiple engineering teams in and outside the organization to build the product successfully.

This RFID-enabled pet door uses a web app to monitor and control access. Image Credit: SolidWorks

Consider the example of SureFlap, a real world solution that solves a common pet issue using a connected solution. This unique product utilizes RFID technology to safeguard from unwanted animal intrusions in your home while providing structured access for your pet via an embedded or worn RFID tag. As such, the ecosystem required to develop such product will include a CAD platform for product design, electronics and Embedded Systems for PCB design and a Web infrastructure that will connect the product with multiple devices.

How SolidWorks Helps

There is a fundamental transformation required for most traditional engineering teams to engineer a connected device and with SolidWorks 2016 this transition becomes stress-free. With robust integration between MCAD and ECAD, designing connected products is whole lot easier. To add to the existing innovative portfolio, SolidWorks PCB powered by Altium further supports in embedded electronic design. There is also number of partner offerings like Xively that transforms SolidWorks designs into connected devices, similar to what SureFlap is using for their pet care solutions.

With additional tools like simulation and data management, SolidWorks can serve as an end-to-end product design and innovative platform that can help you make seamless transition to the connected world.

Filed Under: Appliance engineering + home automation, Rapid prototyping