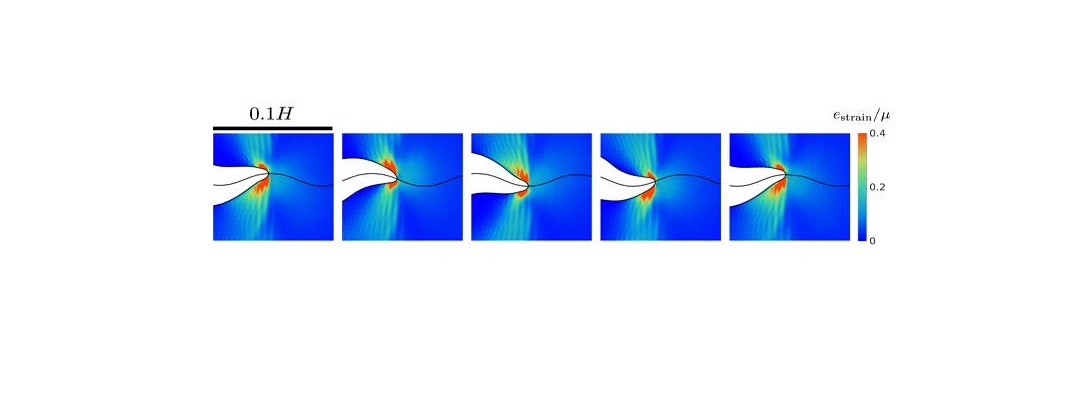

The trajectory of a crack tip, showing one cycle of oscillation. The horizontal wavy line shows the trajectory of the crack tip. Image credit: Weizmann Institute of Science

It is said that a weak link determines the strength of the entire chain. Likewise, defects or small cracks in a solid material may ultimately determine the strength of that material – how well it will withstand various forces. For example, if force is exerted on a material containing a crack, large internal stresses concentrate on a small region near the crack’s edge. When this happens, a failure process is initiated, and the material might begin to fail around the edge of the crack, which could then propagate, leading to the ultimate failure of the material.

What, exactly, happens right around the edge of the crack, in the area in which those large stresses are concentrated? Prof. Eran Bouchbinder of the Weizmann Institute of Science’s Chemical Physics Department, who conducted research into this question together with Dr. Chih-Hung Chen and Prof. Alain Karma of Northeastern University, Boston, explains that the processes that take place in this region are universal – they occur in the same way in different materials and under different conditions.

“The most outstanding characteristic we discovered,” said Bouchbinder, “is the nonlinear relationship between the strength of the forces and the response taking place in the material adjacent to the crack. This nonlinear region, which most studies overlook, is actually fundamentally important for understanding how cracks propagate. Most notably, it is intimately related to instabilities that can cause cracks to propagate along wavy trajectories or to split, when one would expect them to simply continue in a straight line.”

By investigating the forces at play near the crack’s edge, Bouchbinder and his colleagues developed a new theory – published recently in Nature Physics – that will enable researchers to understand, calculate and predict the dynamics of cracks under various physical conditions. This theory may have significant implications for materials physics research and for understanding the ways in which materials fail.

Islands of softness

Exploring a different topic, in a paper that recently appeared in the Proceedings of the National Academy of Sciences of the United States of America (PNAS), Bouchbinder and a group of colleagues investigated the fundamental properties of the “glassy state” of matter. The glassy state can exist in a broad range of materials if their liquid state is cooled quickly enough to prevent them taking on an ordered, crystalline state. Glasses are thus disordered, or amorphous, solids and include, for example, window glasses, plastics, rubbery materials and amorphous metals.

Even though these materials are all around us and find an enormous range of applications, understanding their physical properties has been extremely challenging, owing, in large part, to the lack of tools for characterizing their intrinsically disordered structures and characterizing how these structures affect the materials’ properties. Dr. Jacques Zylberg of Bouchbinder’s group, Dr. Edan Lerner of the University of Amsterdam, Dr. Yohai Bar-Sinai of Harvard University (a former PhD student of Bouchbinder’s), and Bouchbinder found a way to identify particularly soft regions inside glassy materials. These “soft spots,” which are identified by measuring the local thermal energy across the material, were shown to be highly susceptible to structural changes when force is applied. In other words, these soft spots play a central role when glassy materials deform and irreversibly flow under the action of external forces. The theory developed by the researchers thus brings us a step closer to understanding the mysteries of the glassy state of matter.

—

Prof. Eran Bouchbinder’s research is supported by the Rothschild Caesarea Foundation; and Paul and Tina Gardner, Austin, TX.

The Weizmann Institute of Science in Rehovot, Israel, is one of the world’s top-ranking multidisciplinary research institutions. Noted for its wide-ranging exploration of the natural and exact sciences, the Institute is home to scientists, students, technicians and supporting staff. Institute research efforts include the search for new ways of fighting disease and hunger, examining leading questions in mathematics and computer science, probing the physics of matter and the universe, creating novel materials and developing new strategies for protecting the environment.

Filed Under: Materials • advanced