For decades, commercial off-the-shelf (COTS) technologies have been migrating into industrial automation applications, providing expanded functionality. Control room workstations and local human-machine interfaces once ran on proprietary operating systems, but most are now Linux- or Windows-based, with dramatically lower costs and increased capabilities. In the same timeframe, industrial communications have advanced from dedicated and limited methods to primarily Ethernet- and CAN-based standard protocols, with significantly better performance.

At ATX West, Phytools showcased RevPi for compute, connectivity, and calculation-intensive operations in the control room.

While proprietary PLCs were the de facto industrial automation standard for decades, their intrinsic limitations are well known and have constrained contemporary demands for connectivity and processing power. Innovative advances in the IT space have opened the door to a wider breadth of more capable solutions, such as those offered by industrialized Raspberry Pi devices.

Earlier this year at ATX West, Phytools showcased one such device: the Revolution Pi (RevPi). This versatile edge device exploits the economies of scale derived from the millions of Raspberry PIs in service to provide users with extended functionality in a robust package and at a much higher price/performance ratio than traditional PLCs.

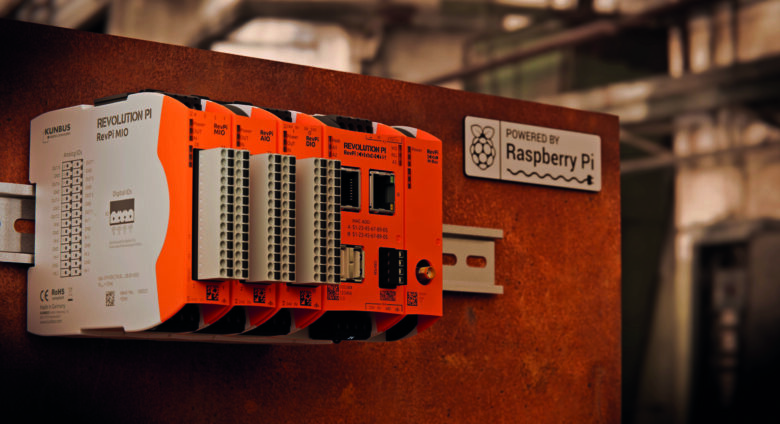

RevPi is ideal for tackling a variety of industrial needs in the control room, including compute, connectivity, and calculation-intensive operations. The device was born in 2016 with the launch of an open-source industrial PC (IPC) based on the Raspberry Pi Compute Module. Engineered and manufactured in Germany by Kunbus, this low-cost, scalable, and industrially-oriented controller embodied the ideals of the Raspberry Pi, making no secret of the underlying hardware, source code, or software.

By ruggedizing Raspberry Pi — with an installed base numbering in the tens of millions — users can realize both reliability and performance benefits. The RevPi platform is designed for industrial environments, and users will appreciate its intrinsic openness, compact size, and application flexibility from both hardware and software standpoints. Development efforts can be accelerated because the platform can be programmed and deployed quickly compared to more traditional options due to its support for a wide range of OT and IT languages.

Elements of the Raspberry Pi are engrained in its DNA, but under the hood the RevPi is ruggedized with IEC, UL, and additional industrial ratings, including the EN61131-2 standard.

With a modular structure, RevPi can be supplemented by digital or analog I/O modules, and its DIN rail housing ensures easy installation in many environments. It is expandable with fieldbus gateways, enabling industrial network connectivity via protocols like PROFINET, PROFIBUS, EtherNet/IP, EtherCAT, Modbus RTU, and Modbus TCP/IP.

RevPi’s operating system (OS) provides the determinism of a ruggedized real-time OS (RTOS) with the versatility of a standard personal computer OS. This provides the real-time performance of an industrial controller with the flexibility to host any application that can run on a standard Raspberry Pi or Linux platform.

By leveraging its RTOS functionality, RevPi can be deployed as a soft PLC, made viable with applications available in its dedicated online shop, including CODESYS. The platform also includes native support for all Linux and Python scripting, providing nearly limitless customization opportunities.

With so many options, selecting the right hardware and software combinations can be daunting, and end users may need some assistance configuring systems and ordering the right components. This is where Phytools comes in, as a qualified value-added reseller (VAR).

Phytools helps users brainstorm system requirements and determine the ideal configurations and deployments to meet application needs. Phytools personnel can help specify the correct components, while providing suggestions for upgrades and expansions.

Additionally, VARs like Phytools can facilitate the design of custom-built devices inside and out, specific to an OEM’s firmware and branding needs. This service helps larger manufacturers meet application-specific software and functional needs, while advancing brand recognition among their customers.

Phytools

phytools.com

You may also like:

Filed Under: PLCs + PACs