The convergence of Operational Technology (OT) and Information Technology (IT) systems may help manufacturers embrace new service offerings using web-based business models.

Many years ago one of my distributor partners took me to do an automation demo for a very large industrial OEM. Afterward we went into a stockroom, where she noted on a clipboard all the components she supplied to them that needed to be re-ordered.

The form was dropped into the inbox of a Purchasing Agent on our way out.

Increased business intelligence

This memory came back into my mind as I was thinking about new business models for manufacturers that may result from the Industrial Internet of Things (IIoT). Besides a purchase order being issued, I’m sure the information on that sheet made its way, probably manually, into an ERP (Enterprise Resource Planning) system.

Supplier-managed inventory is not a new concept. Imagine, though, if a data source for an ERP system was one level “lower” than supplier EDI (Electronic Data Interchange) and accessed directly from a machine?

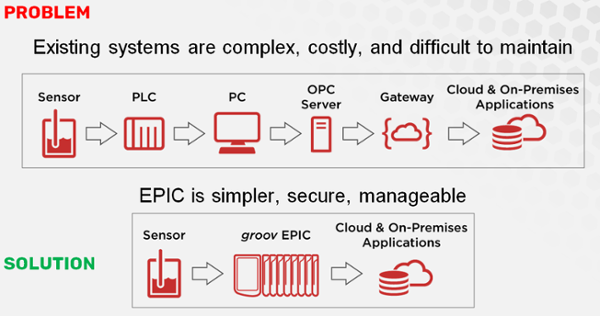

Advances in automation technology today are helping make this data exchange with IT software and cloud platforms simpler. Opto 22’s new groov EPIC (Edge Programmable Industrial Controller), for example, contains IIoT-enabling tools that eliminate the PCs, OPC servers, gateways, and integration that were often required by traditional PLCs.

With the OT data more easily available to IT systems, business leaders may ask themselves, “What opportunities does the connected enterprise present for my organization?” The answer is likely to be new services that use internet-based business models.

IoT-Based Services

A lot has been written and talked about how the convergence of OT and IT can help industrial companies operate more efficiently, reduce downtime, increase profitability, and do things like move from preventative maintenance to predictive.

Most of these outcomes are facilitated by making plant floor data available to software platforms that can combine it with other data to perform advanced analytics. What about manufacturers using this new business intelligence to serve or add value to their customers? Many forward-thinking companies are leveraging IIoT technologies to develop new business models based on delivering service rather than just a product.

I’ve been using supply-chain integration as an example, and it is one area that previously product-oriented manufacturers are exploring to be more service focused. In today’s competitive environment where differentiation on product alone is increasingly difficult, drivers include things like developing closer relationships with customers and improving business intelligence through customer feedback.

Some companies are even looking at integrating CRM (Customer Relationship Management) & Marketing Automation platforms with operational and enterprise data. With this approach, new services that could add value for their customers include PLM (Product Lifecycle Management), faster product development, data warehousing, and product customization.

Product-as-a-service

A compelling case for the use of internet technology to provide service to customers is with OEMs and machine builders. The idea of delivering a machine to a customer and providing remote support (commissioning, troubleshooting, maintenance) as a service is also not new. The difference today is that IIoT-enabling technologies in automation have removed some of the IT barriers and made it more feasible. My colleague Dan White covers this well in his post, Outbound! Monitor OEM Machinery with little to no IT involvement.

Filed Under: Opto 22 Sponsored Content