Reduce motor heat by reducing idle and running current — or switch to closed-loop control.

Eric Rice | Applied Motion Products

Step motors are widely used motion-control devices because of their simple setup and accurate positioning with an open-loop configuration. But problems associated with heat generation can arise. That’s because the drive that powers an open-loop step motor doesn’t use feedback to control the amount of current provided to that motor. Instead, the drive provides full current at all times … regardless of torque demand on the motor. So the motor consumes power at excessive rates …. wasting energy and generating avoidable amounts of heat.

In some applications, operators run open-loop step motors with as much current as possible to generate the most torque possible. That ensures the motor will reach its position in the application. But as current increases, so does motor temperature. If motor temperature rises too high, windings short and the motor ceases to function. So design engineers (and motor end users) must find ways to maximize motor torque while avoiding motor overheating.

One industry approach is to set the drive to give the motor its rated current. Doing that will make the motor hot but not too hot. It’s normal for step motor temperatures to reach 70°, 80°, or even 90°C. While these temperatures make it too hot to touch the motor, the motor itself is unharmed.

But how else can design engineers (and motor end users) reduce motor heat? Here we’ll explore three more ways:

- Reduce idle (holding) current

- Reduce running current

- Switch to closed-loop control

First — Reduce the idle (holding) current for the motor

Many motion control applications need the most torque when the motor accelerates and decelerates to meet its mark. But when the motor idles, or holds position, it requires much less torque. These instances are a good time to reduce motor current.

Most modern stepper drives do this automatically. For example, the drive might reduce idle current to 50% of the running current. More sophisticated stepper drives let design engineers program the idle current to any value between 0 and 100%. If a step motor spends even a modest amount of time sitting still, reducing idle current has a significant impact on motor heat.

Second — Reduce running current

Many design engineers err on the side of caution when selecting a step motor — often choosing a motor with more than enough torque (rather than just enough) for the application at hand. In these scenarios, it may be possible to reduce the motor’s running current with some trial-and-error testing. Basically, this requires reducing running current by a small amount and monitoring the motion output. If this trial run proves successful, reduce running current again and retest motor performance.

Continue making adjustments until the motor mispositions or stalls. Then slightly increase the current so the motor resumes accurate positioning. In some cases — especially when a step motor is oversized for an application — the engineer can reduce running current enough to measurably reduce the temperature of the motor.

Third — Switch to a closed-loop step motor system

The most dramatic reduction in heat generation occurs when replacing an open-loop step motor system with a closed-loop step motor system. Step motors are operable within a servo control loop when outfitted with a high-resolution encoder and powered by a suitable closed-loop drive. This relatively new system configuration necessitates that the engineer replaces the application’s motor and drive. But the magnitude of temperature reduction is usually worth it.

To review, a closed-loop step motor system uses feedback loops to accurately control step motor current, velocity, and position. The current loop ensures that the current provided to the motor by the drive is only the amount needed to meet torque demand. When the motor isn’t producing torque (or producing anything less than maximum torque) current to the motor automatically drops accordingly. This closed-loop control scheme significantly improves motor temperature … reducing it by as much as 50% or more in some applications.

Additional benefits of closed-loop steppers are quicker acceleration and higher throughput (up to 50% more torque than rated holding torque) as well as quieter operation (even to 10 dB quieter) because there’s less current in the motor windings. Plus without stalls, system accuracy is higher.

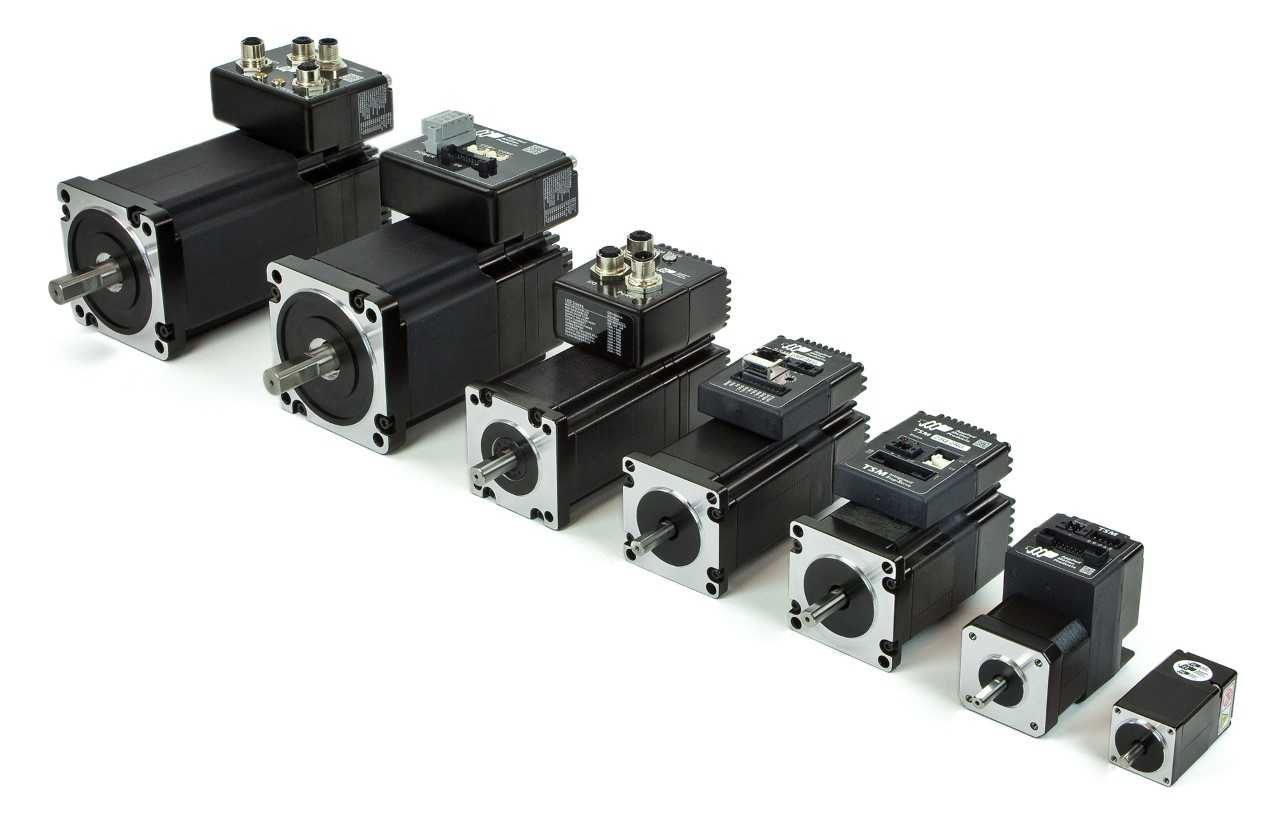

Closed-loop step motors incorporate a high-resolution encoder and are driven by an integrated, closed-loop drive that automatically reduces current to the motor when the load isn’t demanding torque.

Test results confirm that closed-loop step motors draw current only when needed, so they run cooler and with less power consumption than open-loop options. Consider actual tests that run both the open-loop and closed loop variations to get the same motion profile:

- Acceleration = 100 rev/sec2 and deceleration = 100 rev/sec2

- Distance = 5 rev and speed = 10 rev/sec

- Dwell time = 0.1 sec

Both carry a set load inertia and rotor inertia and operate from a 48-Vdc power supply). Results in the graph accompanying this piece show that the average power consumption of an open-loop stepper system delivering such output uses 43.8 W. In contrast, a comparable closed-loop stepper system consumes only 14.2 W to deliver the same routine. That reduced power consumption translates into less heat generation and lower energy bills.

Results from tests conducted by Applied Motion Products confirm that closed-loop stepper systems consume less current than comparable open-loop stepper systems — and stay cooler too.

Applied Motion Products| applied-motion.com

Eric Rice graduated with an Electrical Engineering degree from theUniversity of Illinois Urbana-Champaign.

He joined Applied Motion Products as an applications engineer in 1997 and specializes in step motors, servo motors, drives, and controls.

Filed Under: Drives (stepper) + amplifiers, Motion Control Tips

Tell Us What You Think!