By Edited by Laura Carrabine, Senior Editor

In the discrete manufacturing world between 1/3 and ½ of the CAD systems are 3D. The rest are used for 2D drafting. Although some tasks will always be done more efficiently with 2D CAD, these figures suggest many organizations have yet to employ 3D methods. The good news for potential second-half adopters is that they can benefit from experienced users who have been using 3D for 10-20 yrs. Here are a few rules that 2D CAD users should consider when shopping for their first 3D system.

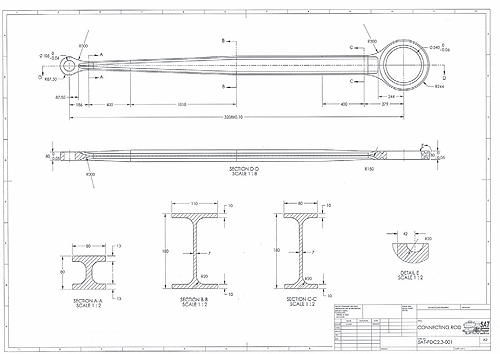

Be sure the 3D CAD system you buy can export your drawings in popular formats such as PDF, DXF, and DWG. Here is a detailed engineering drawing of a connecting road for a steam locomotive.

Image courtesy of David Wardale of the 5AT Project.

Capable, efficient 3D design

The core of 3D CAD is a 3D master model that is used for all aspects of manufacturing: product design and verification, drafting, tool design, numerically controlled tool programming, and inspection. The 3D model must accurately represent every part in your company’s products and the relationships among them. To maximize efficiency, you should be able to design in 3D with as few steps as possible without compromising product quality.

Design automation allows reuse of existing designs to create new configurations including 3D CAD models, drawings, and bills of material.

When evaluating CAD software, find out how efficiently each package creates the types of products your company makes. For instance, if you deal with sheet metal parts, pay attention to the special tools for creating them and automatically generating flat patterns.

Because changes are inevitable, assess how hard it is to modify parts and assemblies. A CAD system that can make your company’s designs with even 20% fewer steps will offer important cost advantages compared with systems that are less efficient. A 3D CAD system that offers the best value will combine technical capabilities with reasonable cost of ownership.

Compatibility with customers and suppliers

Try to choose a CAD system that is popular in your industry and supplier community. This choice will eliminate the need to translate files from one system to another. Also, look at each system’s ability to import files from other systems. Make sure your CAD supplier supports international standards such as STEP, IGES, VDA, and IDF. Evaluate tools for repairing damage to imported shapes, how easy they are to use, and how well they work. If your company must translate many files from several brands of CAD systems, check the direct translators available and also those from third parties that specialize in translator software.

Drafting tools that meet your standards

Even though you will be designing in 3D, your suppliers and factory staff will need drawings. For that reason, be sure any 3D CAD system you buy can make drawings to your current standards for dimensions, tolerances, lettering, and parts lists. And, be sure your drawings can be exported in popular formats such as PDF, DXF, and DWG.

Reliability and stability

3D design systems are more complex than 2D drafting systems. There are no real standards of measures of reliability for CAD as there are for many types of systems and machinery. Browse customer forums and engineering blogs for frequent reports about instability or software bugs. Ask companies that own 3D CAD in your city or industry how often then crash or lock up.

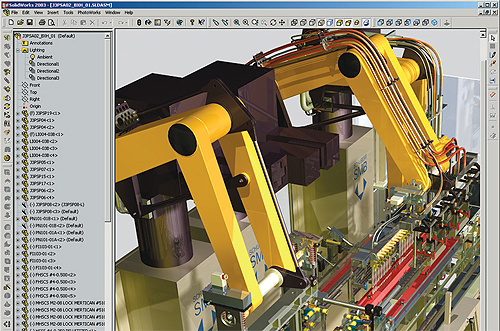

If your company makes large assemblies, be sure any CAD product you select is capable of handling them efficiently. Some systems slow to a crawl when handling complex designs with high part counts. Pay particular attention to assembly performance if your product contains complex freeform shapes, helical sweeps, or arrays of holes or other features.

Built-in applications

3D CAD can be even more productive with special-purpose software for design automation and analysis. If you need to simulate physical behavior such as kinematics, dynamics, stress, deflection, vibration, temperatures, or fluid flow, look for a system that has integrated analytical tools or efficient interfaces to your preferred analysis software.

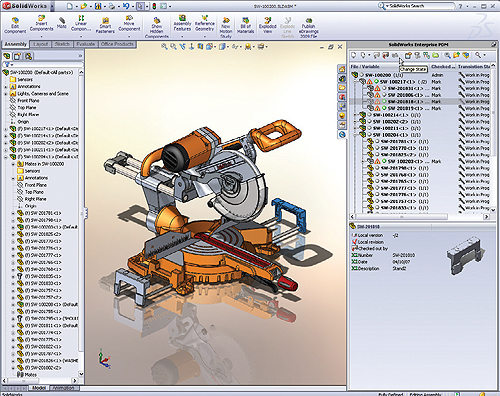

Firms with more than just a few designers need product data management (PDM) software integrated with their CAD tools. Files from 2D CAD systems can be organized in directories. But because the relationships among files in 3D systems are so complex, an automated system to store and organize them is necessary. Without PDM, you can unknowingly overwrite each other’s work and waste a lot of time.

Integrated PDM software enables groups of designers to work together efficiently on common projects.

PDM systems can help you find existing parts to re-use instead of reinventing them. PDM systems also generate material lists for cost estimating and feed data to manufacturing resource planning (MRP) systems. More advanced PDM software can automate change-control processes to assure that out-of-date or unreleased information is not sent to factories or suppliers.

In addition, make sure any system has a complete and well-documented application programming interface (API). Good APIs let you write your own design-automation programs. They can also make it less costly for third parties to integrate niche applications with your CAD system.

Short learning curve

Adopting 3D methods requires training and experience. So, choose a system that easy to learn and capable. Look for a system that has a consistent user interface throughout. Be sure design and drafting procedures flow logically from start to finish.

The process of developing your own training materials is costly. Choose a system with built-in tutorials, an array of computer-based training aids, and a vibrant online community that lets workers ask questions and get answers. You will also want a system that is taught in local schools and universities so you can hire students who are ready to work.

Not all the criteria listed here apply to every organization. Making an intelligent choice requires careful thought and deep knowledge of your company’s engineering needs. Engage with at least three vendors to educate yourself about the capabilities of available software packages and dealer support organizations.

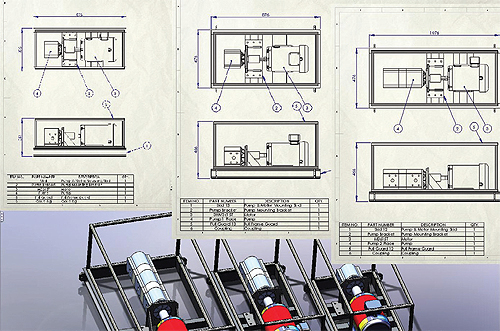

Make sure your 3D CAD system can handle designing large assemblies.

Image courtesy of Gerhard Schubert GmbH.

Solidworks

www.solidworks.com

::Design World::

Filed Under: Software • 3D CAD, ENGINEERING SOFTWARE

There really are a surprising number of factors that you have to make sure your modeling system has before you choose one. I particularly like that the article recommends choosing one that has drafting tools that meet your standards. That way you can learn the program much faster without having to adjust to too many of the new tools.