Natasha Townsend, Associate Editor

Despite the higher initial investment, the speed of ultrasonic welding as a joining process makes it an attractive process during automated production. During the process, ultrasonic vibrations generated through the use of electrical voltage melt the plastic material precisely at a defined joining point or area and create a homogeneous connection. “Cycle times of up to 80 cycles per minute or even higher can be realized, depending on the weld time required, usually between 200 and 500 milliseconds,” said Uwe Peregi, executive vice president and general manager of Herrmann Ultrasonics. A warm-up phase for the welding tools or lengthy cooling periods of the welded parts are not required; which saves time. The parts can undergo the next processing step immediately. Important for the successful implementation of the technology is good application consultation in the run-up phase, especially with component design to achieve the best possible focusing of the ultrasonic vibrations in the joining area.

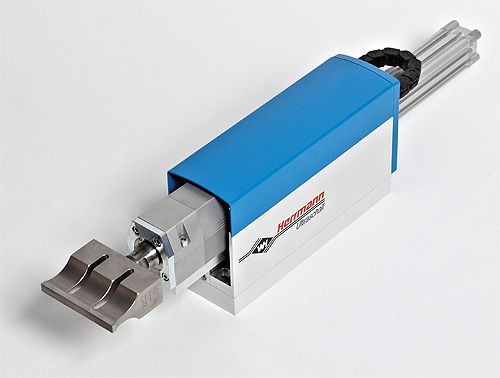

The 35 kHz VE COMPACTLINE, from Herrmann Ultrasonics, is a smaller ultrasonic welding system suitable for robotic applications because of its lighter weight.

In automation, however, ultrasonic generators must withstand long duty cycles, as problems often result in long downtime and high outage costs.

An ultrasonic system will usually be under the control of a PLC either through I/O, or a fieldbus system. Most ultrasonic weld systems are compatible with Profibus, DeviceNet and Ethernet/IP networks.

A fieldbus interface lets you:

• Configure and parameterize applications

• Log measured values and conduct external analysis

• Collect and analyze fault and error diagnostics

• Select memory for parameter sets of saved and set-aside applications

• Control the ultrasonic weld process (start)

• Gather data about the status of the weld processes

In the production sequence the ultrasonic weld station is started by a signal; then, the station performs the weld process autonomously:

• Moving the Sonotrode to the component

• Triggering

• US welding/staking

• Hold time

• Moving the Sonotrode to home position

• Message to the overriding controller (PLC) whether welding was successful/unsuccessful

An ultrasonic system consists of a generator, controller, stack, actuator, and pneumatic unit. This picture shows a typical actuator.

It is possible to use several ultrasonic weld systems in one ultrasonic weld station; this is referred to as multihead applications. The VE SLIMLINE production line for automation applications, is an example. It is available with frequencies of 20, 30, and 35 Hz and with outputs of up to 6200 W. For robot applications the 35 kHz, the VE COMPACTLINE, which is even smaller, is mostly used for weight reasons. The DIALOG controller is used when auxiliary Windows-based software packages are required, when large strokes at very short cycle times are needed, or when the application has a complicated seal design which requires SoftTouch, a gentle touch down of the welding tool to protect the component. Even less complex control concepts, such as the VARIO controller, provide a high degree of flexibility with regard to weld process optimization.

Herrmann Ultrasonics

www.herrmannultrasonics.com

Filed Under: Factory automation, Actuators, MORE INDUSTRIES

Tell Us What You Think!