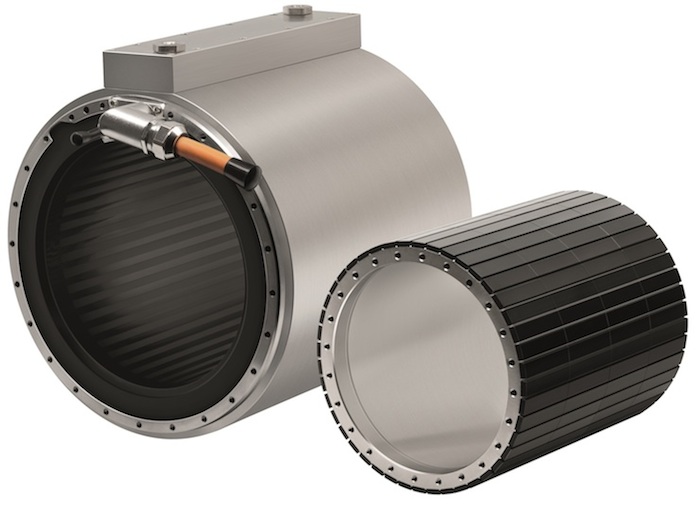

In order to simplify the implementation of liquid cooling with torque motors and ease the mounting into direct-drive machine applications, ETEL announces that their TMB+ torque motor can now be ordered with a closed cooling jacket pre-built around it.

For over a decade, ETEL has been producing high quality frameless torque motors that are used in thousands of machines around the world. Still, several industries have not fully embraced the use of torque motors, and with ETEL’s pre-integrated closed cooling jacket now available in North America through HEIDENHAIN CORPORATION, building a torque motor into a machine is easier than ever.

In the past, the cooling channels outside of a torque motor required that the user design a jacket around it and a number of factors would complicate this procedure such as locations of the liquid inputs and outputs, water tightness, rustproof/non-porous material, etc. Now that ETEL offers a closed cooling jacket for all 62 of its TMB+ torque motor sizes, the design process is simplified and makes direct drive easier than ever as this option allows greater flexibility with the location of the motor. Easier implementation also allows direct drive to expand to many more industries, giving more OEMs the ability to take advantage of its many features.

Each TMB+ motor that comes with a cooling jacket is the exact same model as if it were ordered without which means it offers the same performance as previously listed on its datasheets. It also allows for all varieties of windings, cables, sensors, and bridges along with two output options of an axial or radial output to accommodate any machine design.

For more information, visit www.etel.ch.

Filed Under: Motors (direct-drive) + frameless motors, Motion Control Tips

Tell Us What You Think!