By now, the mystery surrounding the Internet of Things is hopefully starting to dissipate, as more consumer and industrial products join the connected fray.

But even though the definition of IoT may be known, the implications of the connected future might still seem a bit murky. After all, what is the point of all of this connectivity if it’s not providing value? Why should customers care about the industrial Internet of Things? The fact is, once their products have the ability to connect, manufacturers and third parties can deliver more value to their customers—well beyond the sale of the product—by providing an array of solutions and services.

There’s an App for That. One clear way manufacturers can provide value once their products are connected is through software applications that enable their customers to remotely connect to, control, and monitor their products. They can also provide application programming interfaces (API) to allow third parties to develop additional connections to those products. This expands a product’s value by offering not only new functionality but also new ways to interact with it.

This type of value is well documented in home-security systems and appliances, but it can also be present in industrial applications of IoT. For example, take Premier Deicers, a Wisconsin-based purveyor of aircraft-deicing equipment. The company’s Guardian Angel Monitoring System provides remote access to 29 functions on the deicers, from fluid pressures to electrical components. Customers can access live readings of applicable functions on the deicers from anywhere with Internet service.

Make the Upgrade. There’s inherent value in being able to monitor and control products remotely, but manufacturers can take that a step further by upgrading those products that their customers already own. Upgrades will increasingly be delivered via software, and they will become more feasible as manufacturers solve more and more design problems with software rather than with hardware.

The quintessential example of the upgrade model is Tesla. The electric-car company has been delivering over-the-air updates to its Model S for years and recently upped the ante with itsAutopilot update. Deployed wirelessly to all Model S’s in the U.S. throughout the course of a week, the update essentially turned each of those vehicles into autonomous, self-driving cars—that still require ultimate human control (for now).

Gimme the Goods—and Services. Manufacturers can also add value to products by offering services attached to them. These services take advantage of the immense cache of data generated by an IoT product. When combined with data-analysis techniques, these services can become the “secret sauce” that gives certain manufacturers a competitive edge.

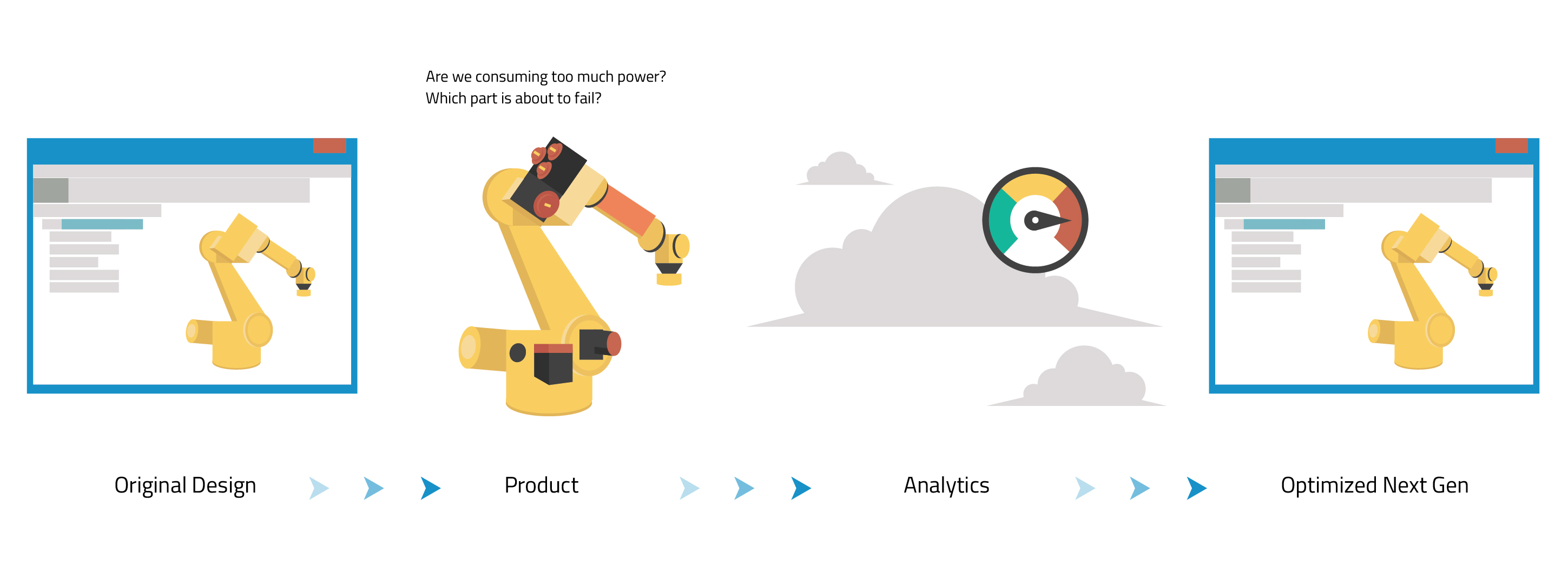

By constantly watching and analyzing the data coming from their products, manufacturers can both draw conclusions from the past and make predictions about the future. For example, as in the image above, one manufacturer could detect that energy consumption is too high under certain conditions and find ways to improve its product’s efficiency moving forward. Another manufacturer could explain why a specific part is failing too often and suggest design improvements to avoid the problem.

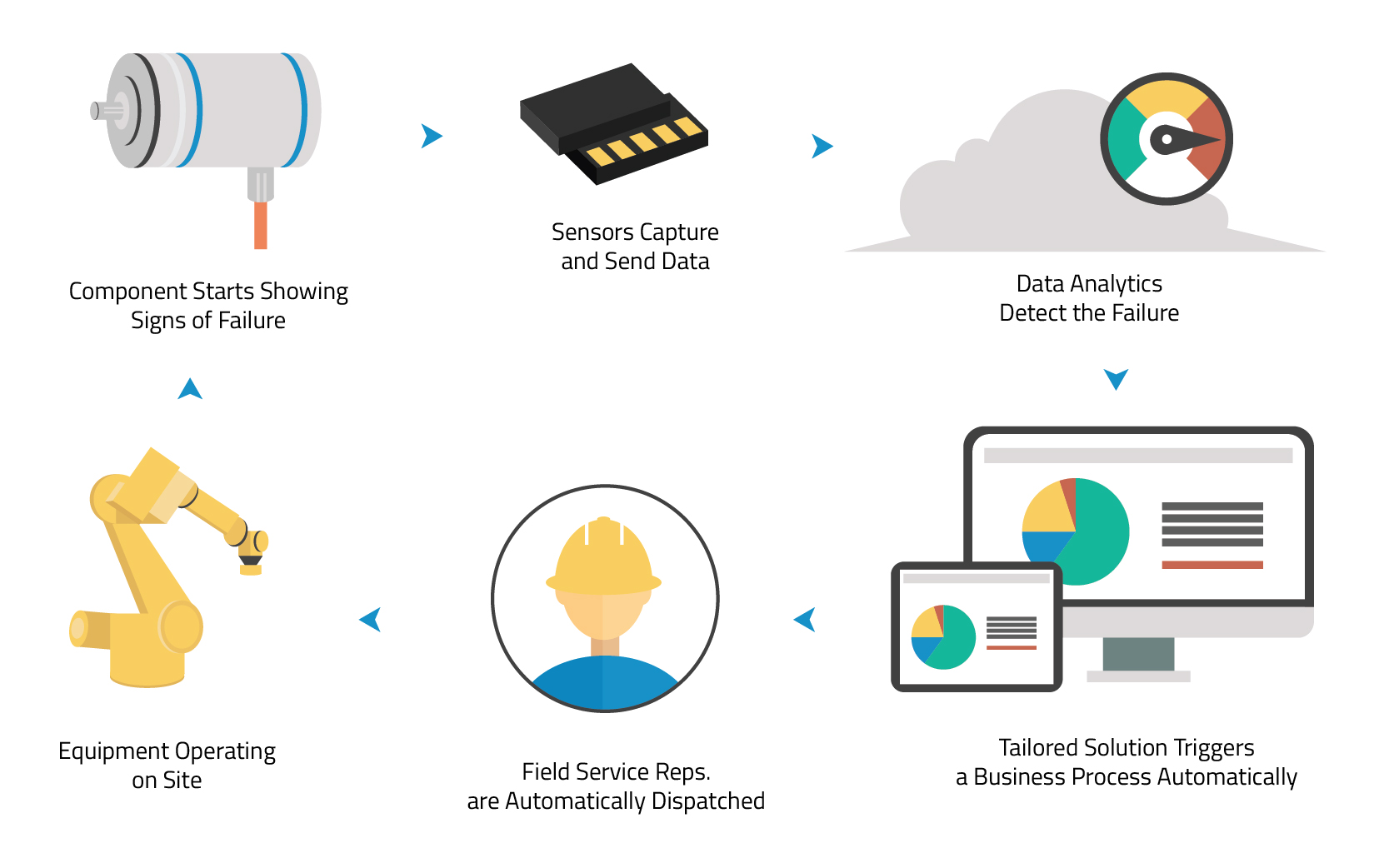

Better yet, that manufacturer could detect when that part is about to fail and schedule maintenance to replace it during planned downtime, which is much less expensive for the customer. This service is widely known in the industry as predictive maintenance, illustrated in the image below.

But the idea of services attached to connected products shouldn’t stop at the individual products—what about providing services at the system level, where products from multiple manufacturers are connected? In that scenario, a manufacturer or a third-party system integrator could monitor the performance of each device in the system and adjust their parameters and behavior to optimize the performance of the system as a whole. The system could comprise similar devices, such as Premier Deicer’s fleet of trucks, or different devices, such as in a smart factory, a smart building, or a smart supply chain. For example, a diesel generator could check a nearby fuel tank and then automatically dispatch a GPS-tracked truck to retrieve the fuel and deliver it.

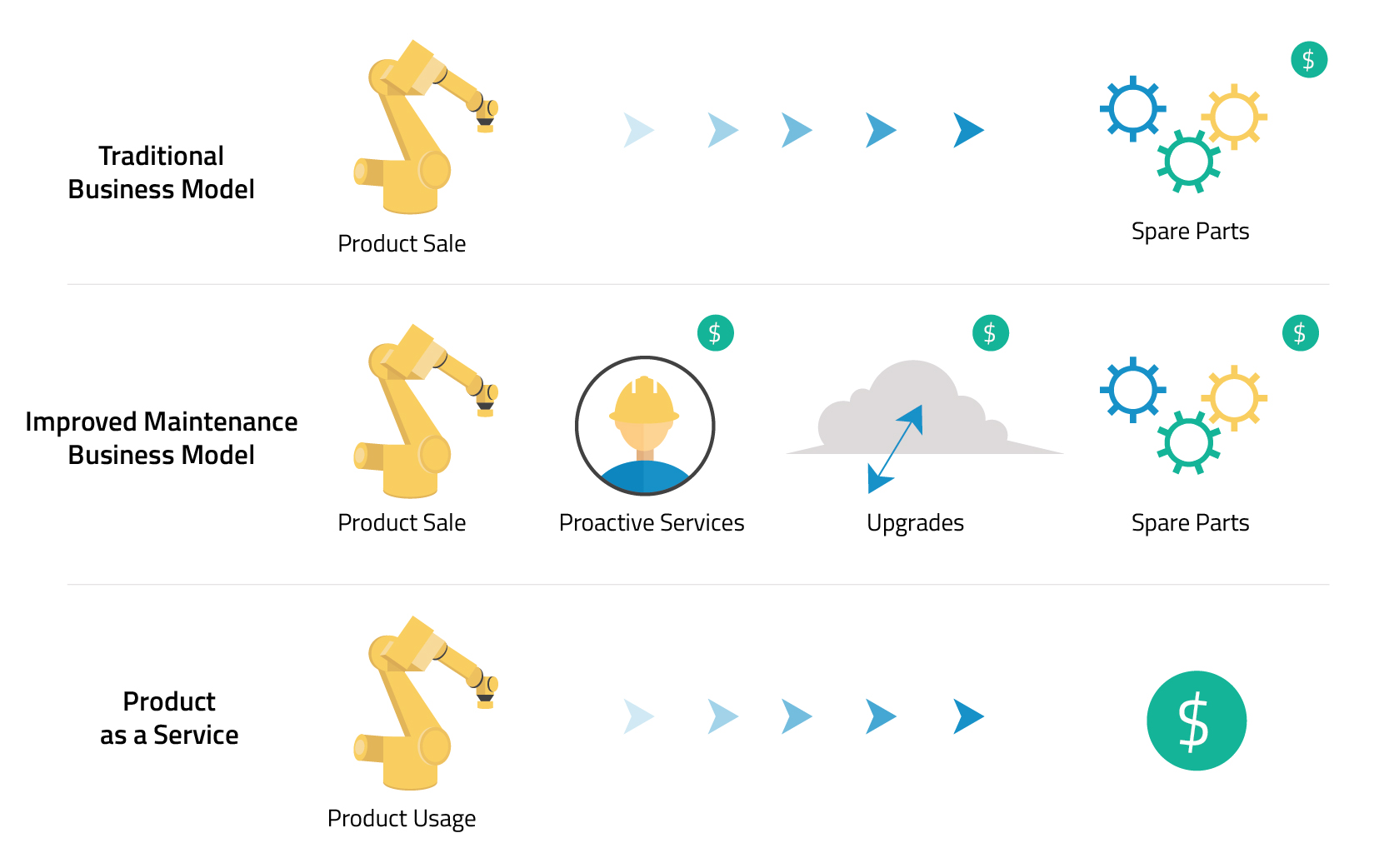

The Birth of New Business Models. One particularly interesting implication of offering services attached to connected products is that they enable manufacturers to implement new business models. For example, in a traditional business model, the customer pays for the product initially and pays later for spare parts, as needed.

In a more sophisticated model, the customer pays for proactive maintenance services. In this situation, the manufacturer remotely monitors the product at the customer site; uses collected data to know when the product needs maintenance; and schedules and performs service and repairs before the product breaks down, normally during scheduled downtime. Because the maintenance is performed proactively, the customer saves money by avoiding unscheduled downtime for repairs. (And because the manufacturer assumes the risks of breakdowns, it’s incentivized to design more reliable products.) This model can also include upgrades, of parts or software, that make the product better.

Taking this idea one step further is the product-as-a-service model. In this situation, the customer doesn’t pay for the product or spare parts, but rather “subscribes” to the product and pays a fixed amount on a predetermined schedule, be that monthly, annually, or quarterly. PaaS puts the onus squarely on manufacturers to keep their products functioning—otherwise, they don’t get paid.

As the IoT becomes even more entrenched in everyday life, the value in the connected ecosystem and the data collected will become even more apparent. It’s estimated that by 2020, the industrial IoT will comprise 16 percent of global GDP and manufacturers will spend more than $500 billion to seize more than $1 trillion in new ROI. And that’s a lot of value to be had.

This blog originally appeared on lineshapespace.com/industrial-internet-of-things-value.

Filed Under: Industrial automation