by Leon M. Attarian, Director of Global Marketing, PennEngineering

Panel fastener assemblies, like captive panel screws, allow for repeated access to equipment while minimizing loose hardware.

Panel fastener assemblies, which integrate captivated screws and mount permanently to an assembly, can securely attach equipment panels, covers, drawers, racks and similar components, while allowing for subsequent and repeated access to equipment. In addition, these fastener technologies can minimize the amount of loose hardware in a system.

This family of fasteners ultimately can promote efficient hardware handling and installation, enable controlled access to equipment whenever necessary, and eliminate the potential for damage to internal components down the road from screws that can loosen and fall out.

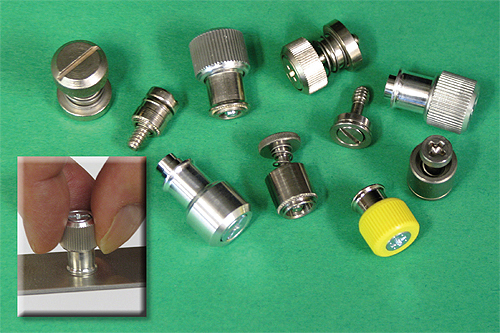

Colored plastic caps are available for fasteners to help with branding and maintenance by designating service levels or operating or maintenance instructions.

The process of selecting a viable captive panel screw for an application can best begin by determining whether the particular fastener’s mounting style will suit the application.

Mounting styles

There are three general standard mounting styles for captive panel screws: self-clinching, flare-mounted or float/flare-mounted. (For printed circuit board applications, additional mounting styles include surface-mount and broaching versions. For the purposes of this article, the focus is on the three general mounting styles, which are suitable for the widest variety of applications.)

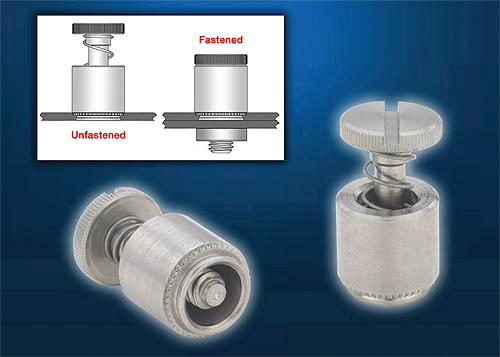

Self-clinching types will install flush (when using shortest screw length) on the backside of a panel—no protrusions on the side of the sheet opposite installation—and will require minimal panel preparation. No secondary operations will be necessary, which can help maximize productivity along the line. The fastener is inserted into a properly sized hole in the mounting sheet and, by applying sufficient squeezing force from a press, becomes a permanent part of the assembly. As a result, the sheet material surrounding the hole is forced into the fastener’s undercut, securing against axial movement and against rotation by a displacer.

Example of a self-clinching type in this family of fasteners. Inset diagram illustrates “unfastened” and “fastened” modes.

For any self-clinching fastener the relationship between fastener and sheet material will be critical. Three basic requirements will be necessary for successful outcomes:

• Metal sheets into which the captive panel fastener will be installed must have adequate ductility to allow the displaced sheet material to cold flow into the undercut.

• Metal sheets into which the fastener will be installed must be sufficiently softer than the fastener so that the fastener itself does not deform during the installation process.

• Sheets must meet the minimum sheet thickness required by the particular fastener. As an example, one basic type of captive panel screw assembly requires a minimum sheet thickness of 0.036 in. (0.92 mm). Typically, there is no specified maximum thickness required for clinching into sheets. Sheet thickness may become a consideration, however, depending on the fastener’s screw length.

Flare-mounted panel fasteners with captive screws can be specified for use in virtually any thin material of any hardness. Unlike self-clinching versions, a flare-mounted fastener’s shank effectively reshapes during installation (without impacting the panel) and will require minimal installation force. These likewise will install flush on the backside of a panel and, unlike self-clinching fasteners, will be appropriate for close centerline-to-edge applications and for use in painted panels, because the paint thickness will not hinder attachment (unlike the self-clinching process) and no marring will occur during installation. (Note: An additional countersink will be required for the mounting hole to keep the flared portion from protruding on the backside of the panel.)

Float/flare-mounted style fasteners can install into any thin panel material (including printed circuit boards), regardless of panel hardness. These are similar to flare-mounted types in that they reshape during installation, require minimal squeezing force with punch and anvil (to flare their retainer) and serve as practical hardware for close centerline-to-edge applications. An added advantage: They can compensate for mating thread misalignment, offering up to 0.81 in. (2.06 mm) of float within the mounting hole.

Narrowing the field

After the appropriate mounting style of a panel fastener with captive panel screw has been selected, designers can turn their attention to various design and performance considerations or requirements to help narrow the field in line with application parameters. Among them are actuation, drive configuration, cap design, thread integrity and positioning pins.

Actuation — Depending on type, panel fasteners with captive screws have been designed for actuation either by hand and/or tool or tool-only. Particularly noteworthy, several types have been specifically UL-approved for tool-only operation and feature fully recessed heads and Phillips drives. These fasteners will ideally suit applications where security or safety issues can be expected to arise.

Tool-only access has, in fact, become a top-of-mind issue due to the EC (European) machinery directive imposing strict safety requirements for machine guarding and the ergonomics of operator equipment. (PennEngineering’s captive panel screws for tool-only access specifically conform with Machinery Directive 200642/EC, which requires such fasteners to remain attached to fixed guards or machinery when guards are removed, meaning loose screws no longer are acceptable.)

Drive configuration — Depending on the fastener, designers can choose from Phillips/slot combinations, Phillips only and slot-only drives, among others. As with all the features at the designer’s disposal, the most appropriate choice will be influenced by the application

Cap design — Among the cap designs (whether for self-clinching, flaring or floating fastener mounting styles), metal versions with large knurled heads promote easier hand operation; smooth metal caps without knurls will be more appropriate for limited manual access; and metal caps with optional DuraBlack finish (also applied to the screw component) will resist scratches and enhance cosmetics in an assembly.

As an alternative to metal caps, colored plastic (PC/ABS) versions have been developed to advance maintenance, functional and/or branding requirements. The plastic caps can be specified in black, red, orange, yellow, green, blue, violet or metallic as standard or custom colors can be supplied. The colors offer the capability to designate service access levels for equipment, color-reference operating and/or maintenance instructions, or conform to end-use aesthetic requirements, among other possibilities.

Thread integrity — Self-clinching, flare-mounted and floating captive panel screws can be engineered with patented anti-cross threading technology, which easily corrects off-angle installations, aligns components and slides through clogged internal threads. Specification of this feature can save time and money by eliminating failures, repairs, scrap and downtime associated with thread damage.

Here’s how the technology works: During initial engagement when threads come into contact, the anti-cross threading feature begins to cam over the female thread. The two thread helixes then align perfectly and fasteners will drive normally and quickly with reduced effort.

Positioning pins — Self-clinching, spring-loaded plunger assemblies offer captive panel solutions serving as positioning pins to quickly and easily move racks, drawer slides, access panels and equipment consoles, among others, to new positions without requiring tools. Standard versions incorporate a unique lockout feature to keep the fastener’s spring-loaded plunger retracted until the plunger pin drops into final position. A simple quarter-turn of the fastener enables the retracted locking and unlocking actions. (Fasteners also can be supplied without the lockout feature.)

Fastener design variations

While the vast majority of panel fasteners with captive screws have been engineered as spring-loaded assemblies, types without springs have been introduced, offering relatively lower-cost design solutions.

A look at the various types of panel fasteners with captive screws. Inset shows an example of a type that can be hand and/or tool actuated.

As a lower-cost alternative to multi-component fastener assemblies, a spinning clinch bolt with one-piece captive screw can provide a practical solution. These fasteners for metal panels benefit from controlled clinching action during installation, which captivates the screw permanently while allowing it to spin freely in the host metal sheet. They provide a reliable means of attachment without use of a retainer or washer (contributing to lower manufacturing costs) and can be supplied with an unthreaded neck for axial float or with a jacking feature or spring for self-retracting. As with some other types, these will be appropriate for close centerline-to-edge applications.

The universe of captive panel screws continues to expand with new variations and innovations. Enlisting the support and resources of an established supplier early in the design stage ultimately can contribute to solid choices and successful outcomes.

PennEngineering

www.pemnet.com

Filed Under: Screws • nuts • bolts, FASTENING • JOINING • locks • latches • pins

Tell Us What You Think!