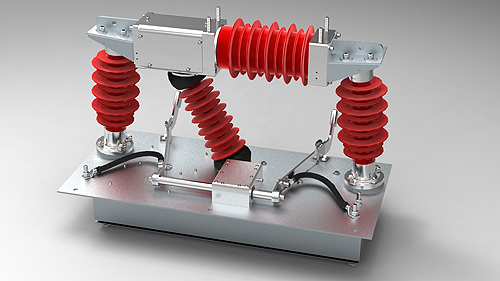

TE Connectivity has developed an enhanced generation of electrical circuit breakers for trains that eliminates the disadvantages associated with conventional mechanical, pneumatic circuit breakers. The innovative VESA vacuum circuit breaker (VCB) for electric trains is the world’s first all electro magnetically operated system for 25 kV and 15 kV vehicles. After five years of development and design evolution based on field data, the VESA VCB impressively demonstrates what is possible: more than 800 units on four continents are providing the utmost in proven reliability and leading the electric rail vehicle market into a new era. VESA VCB performance has been qualified for high- and medium-speed trains (underground, commuter suburban and freight trains) worldwide and operates successfully in a range of varying weather and climate conditions.

All around the globe, public transportation markets are being confronted with major challenges as the constant growth of urban centers puts pressure on commute and travel times, creating a growing demand for green technologies and efficiently engineered railway solutions. One of the worldwide “megatrends” involves the electrification of passenger trains, enabling new efficient solutions that weigh less and use less energy. Electrically operated trains are gaining importance within any country’s transport infrastructure mix. Increasingly, train engineers advocate the line power disruptive technology that plays such an integral role in railway electrification.

Peter Van Loo, general manager of TE’s Rail & Mass Transportation Business, emphasised his company’s orientation towards the future and its customers starting with the development process. He states, “Through close co-operation with our customers, our research team has developed a system with breakthrough benefits for the railway sector. TE’s electro-magnetically operated VESA VCBs are lighter weight than pneumatic circuit breakers, are easy to install, provide higher levels of safety and need less energy to be operated. Providing the market with a solution exhibiting lower total installed cost while allowing the removal of bulky pneumatic systems makes this innovative TE solution an exciting and reliable product for both new designs and refurbishment programs.”

The importance of line power circuit breaker technology

Traditionally, circuit breakers were actuated by compressed air provided by a compressor and reservoir system. The pneumatic infrastructure of the line power circuit breaker is independent from the main pneumatic system that feeds the train brakes. While the additional pneumatic circuit breaker system has been considered a proven technology for decades, pneumatic systems tend to be seen in a more critical light today due to their space and weight requirements, relative complexity, reliability issues and associated maintenance needs. Additionally, pneumatic systems are less energy-efficient as air needs to be compressed and energy is dissipated in the form of heat loss. Actuating the circuit breaker with electric energy in one step eliminates the air compression stage and the energy losses that are associated with it.

Benefits at a glance

• Reliability: The VESA VCB system needs less servicing than conventional pneumatic systems.

• Space & weight savings: The VESA VCB requires a smaller sized air supply and a compressor for the pantograph actuation. There is no further need for pneumatic plumbing. In addition, the VCB is amongst the lightest in its class and is less than half the weight of some pneumatic products on the market.

• Energy savings: The system has low electric power consumption for reduced power demand on the train’s low-voltage system. In addition it offers traction energy savings from the significant overall weight reduction combined with reduced aerodynamic drag.

• Backwards compatibility: The system can be retrofitted as part of refurbishments, refits or major maintenance cycles.

• Customization: The VESA VCB can be customised in several ways. The choices include earthing arms, various operating voltage options, integration of additional control relays and feedback switches.

• Cost-saving potential: TE estimates a savings potential of 120 maintenance hours per installed unit -thanks to self-cleaning insulators and a reduced reliance on pneumatic systems.

TE Connectivity

http://www.te.com/

::Design World::

Filed Under: ELECTRONICS • ELECTRICAL

Tell Us What You Think!