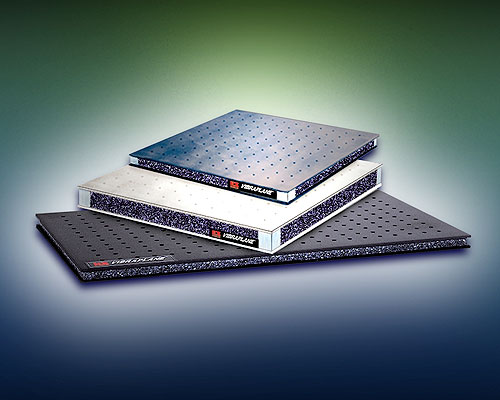

BOSTON, MA – Versatile, high-performance breadboards from Kinetic Systems provide a flat, stable surface for a variety of applications, including mounting or assembling lasers, small optical systems, prototyping, and precise inspections. Available in four standard configurations, Kinetic Systems breadboards feature high natural frequency, nominal broadband damping, and flatness of ±0.004” over a 24” x 24” area. Removable elastomeric iso feet are standard.

Lightweight

Series 5500 VIBRALITE AL nonmagnetic breadboards use a structural core of extruded aluminum with 3/16” anodized aluminum top and bottom skins. They are ideal for small-scale applications that require excellent rigidity and are available 1” or 2” thick in a variety of sizes up to 24” x 48”.

Economical

Series 5600 VIBRALITE SS ferromagnetic breadboards use a structural core of extruded aluminum with 1/8” stainless steel skins. They are available 1” or 2” thick in a variety of sizes up to 48” x 96”.

Honeycomb Core

Series 5700 VIBRALITE HC breadboards are constructed using corrosion-resistant, plated-steel, hexagonal cell honeycomb with a 3/16” ferromagnetic stainless steel top skin and a bottom skin of 3/16” low-carbon steel with a polyurethane finish. The Series 5700 provide high static stiffness and are available 2” or 4” thick in a variety of sizes up to 48” x 96”.

General Purpose

Series 5800 VIBRALITE HCL honeycomb-core breadboards have slightly thinner skins (1/8”) than the Series 5700 but are otherwise identical. They are available 2” or 4” thick in a variety of sizes up to 48” x 96”.

Kinetic Systems breadboards are built with precision tooling and high-quality materials. Epoxy-laminated under pressure with the top skin against a master tool plate, all models offer SPILLPRUF™ tapped mounting holes (1/4-20 or M6 thread), which are sealed off in rows to channel liquids away from the core and simplify cleanup. Custom sizes and cutouts are available – inquiries are encouraged. Optional Level-Lok™ tiedowns fasten a breadboard to another surface.

Kinetic Systems also offers nonisolated legstands for breadboards ranging in width from 30” to 48” and in length from 36” to 72”. With up to 800 lbs. capacity, they are made of 18-gauge steel tubes. The legs can be telescopically adjusted for work-surface heights from 30” to 37”. Legstand accessories such as shelves, drawers, and electrical outlets can be added easily.

Kinetic Systems, Inc.

www.kineticsystems.com

::Design World::

Filed Under: Materials • advanced, Shocks + vibration control • gas springs

Tell Us What You Think!