Automation relies on sensors, switches, motion axes, and actuating devices for production data. Connecting these nodes to controls are I/O modules — usually in the form of remote I/O with standalone hardware. But some new HMIs do double-duty as controllers to simplify integration and directly connect with remote I/O modules. For more information, visit https://www.designworldonline.com/video-weintek-cmt3090-hmi-supports-remote-access-and-control and http://www.weintekusa.com. Also click the links below to watch the quick demonstrations mentioned in the video.

How to create a simple CODESYS project → https://youtu.be/cN0DZqAVRBQ

How to import tags into EasyBuilder Pro → https://youtu.be/XoVPA_thRSo

How to run PLC control → https://youtu.be/9Kha32R64d8

Trace function within CODESYS → https://youtu.be/lu5yC-_cJ48

How to add a module in CODESYS → https://youtu.be/WN03u9hfSy4

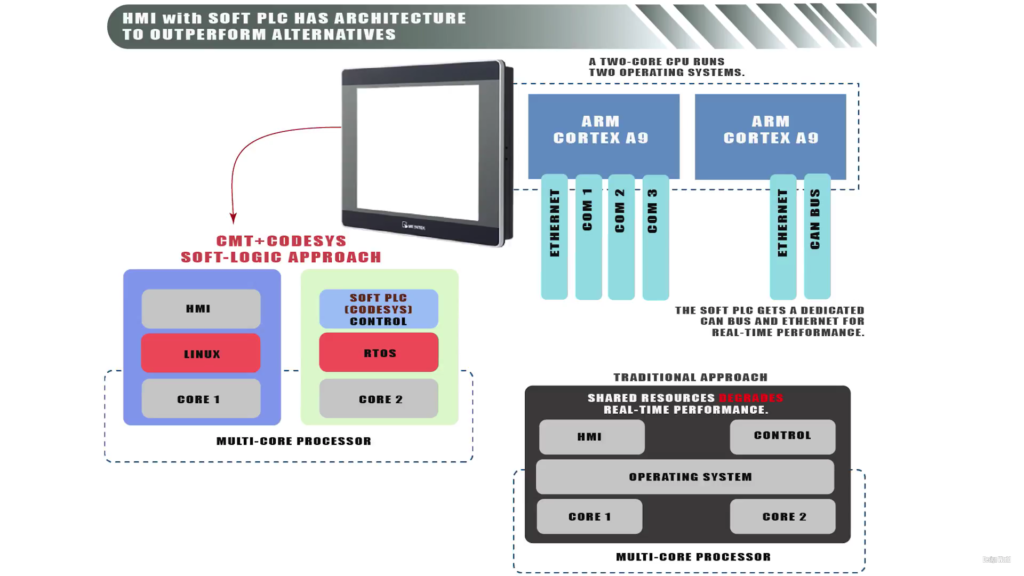

New Weintek cMT controller HMIs do double duty as controls to simplify integration and directly connect with remote I/O. The HMIs have dual processors — one strictly for HMI functions and the other for soft PLC functions. Soft PLC operation supports remote I/O use and elimination of local rack-mounted PLCs and I/O.

In contrast with units having pre-integrated fieldbus interfaces, new I/O modules let design engineers pick from many options. Weintek Ethernet MODBUS couplers daisy-chain to connect disparate device arrays. Then the last port in the series serves as a diagnostics port.

The cMT HMIs then leverage Weintek’s MODBUS TCP/IP and CANopen couplers for networking. Plus the HMIs accept remote I/O analog, digital, and thermal signals — which is particularly helpful in oil and gas and wastewater applications.

Of course, a main benefit of remote I/Os is that they simplify programming by executing simple jobs while freeing the system controls to focus on handling advanced tasks.

Side note on bus communications: Many systems use an internal or local or memory bus to connect internal components. In contrast, Weintek iBus modules get high speeds by avoiding one-by-one SPI and series connections — and instead use parallel I/O connections.

Ethernet couplers work with the Weintek controller HMI. MODBUS TCP/IP slaves include dual Ethernet support and Ethernet cascading — as well as direct support of drivers generated by Weintek EasyBuilder Pro 6.0 software called EBPro for short.

EBPro offers visual project editing and supports communication protocols such as Ethernet/IP and Modbus TCP for easy connection of field devices.

Consider this iR-COP CANopen bus coupler with an iR-DM16 module. It supports baud rates to 1Mbps and allows quick node and baud-rate changes. The coupler also allows remote changes to communication settings — and direct EBPro driver support without the need to import code. Shown here lower right are plug-in modules mentioned earlier.

In traditional components with soft PLCs, symmetric multiprocessing means system resources are shared — which degrades real-time performance. In contrast, the Weintek cMT+CODESYS HMI with soft logic outperforms even some traditional standalone PLCs on the market.

The CODESYS programming environment supports development of code in all five 61131-3 languages … and Weintek cMT HMIs with CODESYS make setup and operation of the HMI’s controller portion faster.

Weintek cMT HMIs communicate with myriad PLCs and directly connect with all types of peripheral devices. Plus cMT HMIs run various protocols, and remote monitoring with is fast, even over Wi-Fi.

EasyBuilder Pro accepts CODESYS code after the programmer exports the symbol configuration for assigning to different components as an XML file — and then imports it into EBPro. Visit the links in this video’s description for how to create a simple CODESYS project, how to import tags into EasyBuilder Pro, and how to run PLC control.

Also see how to setup a trace function, add a module for import into EBPro, and execute direct control through a cMT without a PLC.

Also be sure to visit www.weintekusa.com.

Filed Under: CONNECTIVITY • fieldbuses • networks, Displays • HMIs • operator interfaces • monitors, PLCs + PACs