Scintilla AG cranks out 60,000 power hacksaw blades every day. The blades vary in terms of shape, type of base paint, and imprint. Up to 700 different types of blades can be produced at the plant. That type of volume requires the latest production equipment including vision and inspection software from Cognex. The products help ensure that saw blades are defect-free.

Scintilla AG, a division of Bosch Power Tools, produces thousands of saw blades each day. It uses an automated quality control vision system from Cognex to improve production.

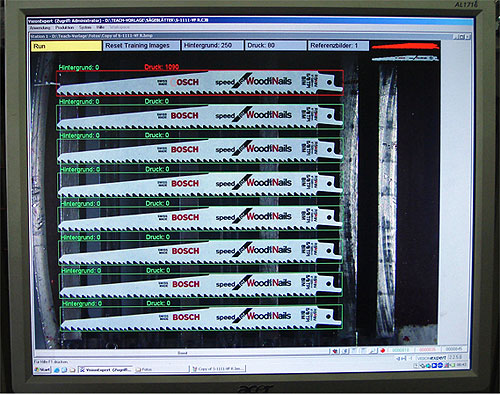

For example, in the finishing area, eight jigsaw blades are inserted into a holder on a rotary transfer machine for a complete quality inspection. The vision system inspects the base paint, and checks for dirt, scratches, or fine lines down to 0.2-mm in size. Next, the system evaluates details on the blade pad imprint to determine the presence and quality of printed text or graphics.

Cognex’s PatMax and PatInspect software products help eliminate manual positioning and adjusting the blades on the factory floor. The shape of the saw blade needs to be taught to the system once and then saved in the checking job. PatMax facilitates the inspection process. The software uses geometrical basic object structures (similar to CAD). Individual blade characteristics such as edges, dimensions, shapes, angles, arcs, and shades are isolated and identified. The 3D relationships between these features of the “learned” image are compared against the real-time image. By analyzing this data, it is then possible to define the object’s position and accuracy. The system simplifies the feature detection process. PatInspect is based on PatMax and detects surface faults and defects. For instance, the software can detect objects that have parts of their shape missing or hidden.

PatMax and PatInspect software inspect saw blades to verify product characteristics such as color, shape, text, and graphics.

The quality control ystem has been in use at Scintilla AG for approximately one year. The system operates on a three to four-shift basis. The rotary transfer machine operates on a 4.5-sec cycle, and completes the vision inspection tasks in 1.8-sec. The company claims it has complete product traceability and optimal production as a result of using the automated system. It reports higher customer satisfaction levels and zero product returns. It plans to implement the system at another plant this year.

Cognex

www.cognex.com

::Design World::

Filed Under: Factory automation, ELECTRONICS • ELECTRICAL, Vision • machine vision • cameras + lenses • frame grabbers • optical filters

Tell Us What You Think!