Melbourne, Florida — VX Corporation announces availability of VX Version 13.

This version contains a number of enhancements that

continue to strengthen VX’s position in the product design and mold

& die markets.

A new filleting engine helps get

more “style” into products. Product designers will realize

increased productivity gains for adding digital images to products with

the enhanced embossing tool that automatically smooths out irregular

surfaces. A new capability for branding and packaging is where text can

be made to follow a circle or spline curve where the text floats above

the curve as the curve’s profile changes and optionally stretches or

shrinks as the curve length changes. This allows manufacturers to

quickly and easily add company and other information to complex shaped

products and containers. Another performance enhancement for designers

is the ability to model with real-time analysis thus giving instant

feedback on aspects such as curvature and draft angles.

Other

features to help product designers visualize new products are a new

photo-realistic rendering engine that brings an “industrial design”

level of rendering to VX. Likewise, textured objects, also new for

Version 13, lets designers get real-time realistic views of products

while they’re being designed.

Mechanical designers will

benefit from motion simulation where animations can be created for

studying moving parts in assemblies. Moreover, assembly interference

can be visually checked with dynamic clipping offering up-close

segmented and internal views of parts and assemblies.

Mechanical designers can get up-close segmented and internal views of parts and assemblies with the new dynamic clipping planes tool in VX CAD/CAM Version 13.

Mechanical designers can now get section views on layouts with

different hatching options that provide a much better view of

assemblies without a lot of manual editing. Mold designers will now be

able to design electrodes faster with the auto-electrode tool that

speeds creation and machining of multiple electrodes. Automatic region

recognition for picking connected sets of faces speeds electrode design

by reducing the number of picks to just a few for complex electrodes

with many surfaces.

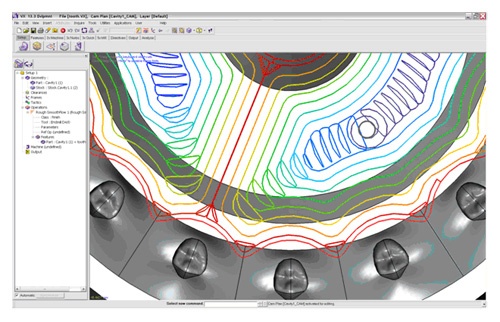

Enhancements to VX’s QuickMill™ for

mold machining include new SmoothFlow™ technology that ensures smooth

finishes for reducing polishing time while maximizing machine tool

efficiency and reducing machine wear and tear. Other CAM enhancements

include Offset3D Feature Aware Machining where tool path motion is

automatically adjusted to preserve fine sharp edged detail; Variable Z

Level machining for containment of simple tool paths for better

finishes with no wasted motions; and XML output to help streamline

shopfloor communication.

VX CAD/CAM's new SmoothFlow technology helps reduce polishing time while maximizing machine tool efficiency and reducing machine wear and tear.

::Design World::

Filed Under: Software • 3D CAD, Software • CAM, ENGINEERING SOFTWARE

Tell Us What You Think!