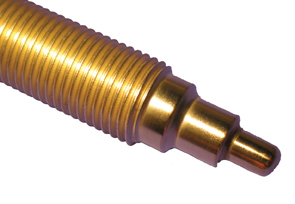

Durex Industries now offers Durexium a multi-layer coating is made up of 16 different layers of Titanium Nitride and Zirconium Nitride deposited using a cathodic arc PVD process at a temperature of 800 °F. The alternating layers produce a synergistic effect that results in a Vickers hardness of over 4400 Hv.

This higher hardness combined with the coatings superior abrasion resistance and lubricity results in wear life of up to 12 times typical non-coated sensors. This option has been shown to be especially effective when extruding or molding plastics reinforced with glass fiber or other abrasive materials. Durexium coating has also been proven to be affective in extremely abrasive pet food extrusion equipment resulting in drastic improvement in wear life over non-coated sensors.

This higher hardness combined with the coatings superior abrasion resistance and lubricity results in wear life of up to 12 times typical non-coated sensors. This option has been shown to be especially effective when extruding or molding plastics reinforced with glass fiber or other abrasive materials. Durexium coating has also been proven to be affective in extremely abrasive pet food extrusion equipment resulting in drastic improvement in wear life over non-coated sensors.

For literature, applications, pricing or more details:

www.durexindustries.com

[email protected]

.:Design World:.

Filed Under: Factory automation, Materials • advanced, MECHANICAL POWER TRANSMISSION, SENSORS, ELECTRONICS • ELECTRICAL

Tell Us What You Think!