Tuning a servo system is a complex and iterative process. It typically requires tuning multiple control loops, each with its own gains (proportional, integral, and/or derivative) to be adjusted, not to mention additional parameters such as acceleration and velocity feed-forward gains and filters to reduce oscillations.

While manual tuning has been the predominant method for many years, most servo drives now incorporate functions that will automatically tune the system. Although in the beginning, auto tuning functions were useful only when the load was rigidly coupled and the system dynamics were relatively simple, more complex algorithms and faster computing power have enabled the development of auto tuning functions that are sophisticated enough to address even the most complex systems, with minimal input or effort from the user.

Auto tuning is based on the same principles as manual tuning. That is, the performance of the motor is evaluated relative to a given command, and the servo drive automatically adjusts the gains until values are found that give the best performance. In most cases, the auto tuning process can also add filters to the control loop to suppress oscillations caused by resonance frequencies in the system.

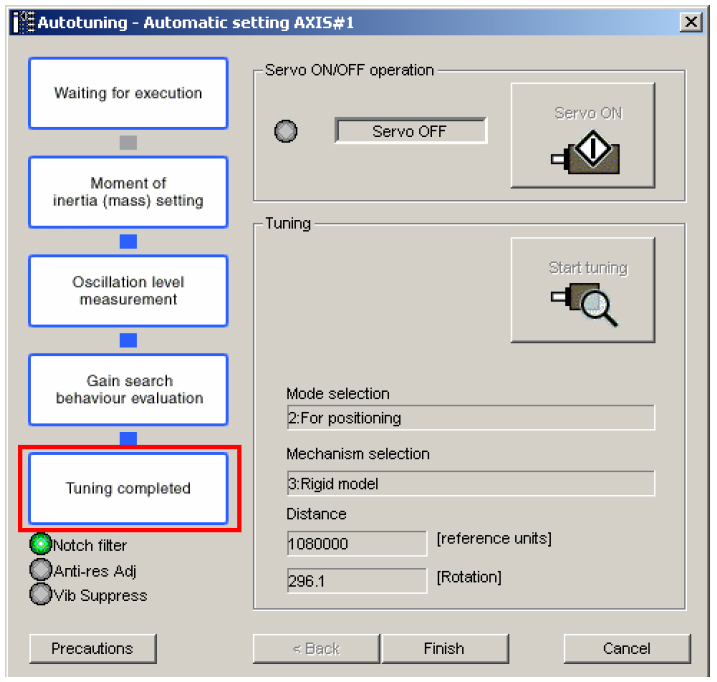

As the motor and load are driven in the auto tuning process for this Yaskawa servo drive, the drive automatically determines the inertia of the system, measures oscillations, and sets, evaluates, and optimizes the control loop gains.

Adaptive tuning is similar to auto tuning, but goes one step further and allows for a wide range of parameters that will provide stable control of the servo system. Adaptive tuning continuously monitors the system’s performance and, if necessary, adjusts the control loop gains and filter parameters to compensate for unknown or changing load conditions during the system’s operation. The key to adaptive tuning is that it runs continuously in the background of the control system to detect resonances by analyzing the frequency response of the torque loop.

One parameter tuning typically refers to a tuning feature that can be used to “fine tune” the system’s response after adaptive tuning has been configured. The term “one parameter” tuning comes from the fact that a single parameter is used to configure multiple system attributes, including gains, filters, friction compensation, and control of resonance. This improves the responsiveness, stability, overshoot, and overall efficiency of the system.

To see (and hear) a linear system with poor servo tuning, and how it can be corrected with a simple auto tuning procedure, check out this video from Bosch Rexroth.

Feature image credit: Performance Motion Devices, Inc.

Filed Under: Motion control • motor controls, Motion Control Tips

Auto tuning is MUCH different than manual tuning. First auto tuning requires generating a model of the open loop system whereas manual tuning does not. The process of generating the open loop model is called system identification. This step requires exciting the system with a control signal and monitoring the response. The computer then uses an algorithm to quickly generate the model.

The next step is pole placement. If you know where you want the poles then all gains can be generated at the same time. Again this is much different than manual tuning where the controller gains are changed one at a time without regards to keeping the poles at any particular location.

Adaptive tuning is tricky. The system gain can only be changed when moving at a constant velocity. Likewise time constants should only be changed when accelerating or decelerating. When the axis is stopped the gains shouldn’t be update at all except for maybe an offset.

I haven’t heard the term one parameter tuning but if it is using one parameter to adjust the pole locations then that is what we do. We provide a slider bar that increases the PID gains together so the closed loop poles stay on or close to the negative real axis in the s-plane. That results in a response in the time domain that has no sine or cosine terms ( No over shoot ) and a decay term exp(-lambda*DeltaT) where the pole locations are at -lambda. Making the magnitude of lambda bigger results in a faster decay in errors and a faster response.

Thank you Peter for giving us your very clear explanation.