Pallet conveyors — conveyors that move products on individual carriers, or pallets — offer significant flexibility for assembly, automation, and inspection processes, with the ability to move products asynchronously in virtually any configuration imaginable, including curves, turns, and small elevation changes. And beyond these basic movements, special modules for pallet conveyors can transfer products horizontally or vertically — to another conveyor or offline process — or re-orient the pallet (and, therefore, the product) on the conveyor without changing the direction of transport.

The conveyor units described here are often referred to as conveyor “modules” because each one is essentially a complete section of conveyor, with its own drive mechanism, switches, stops, brakes, and, if necessary, enclosure.

Lift and rotate conveyor modules

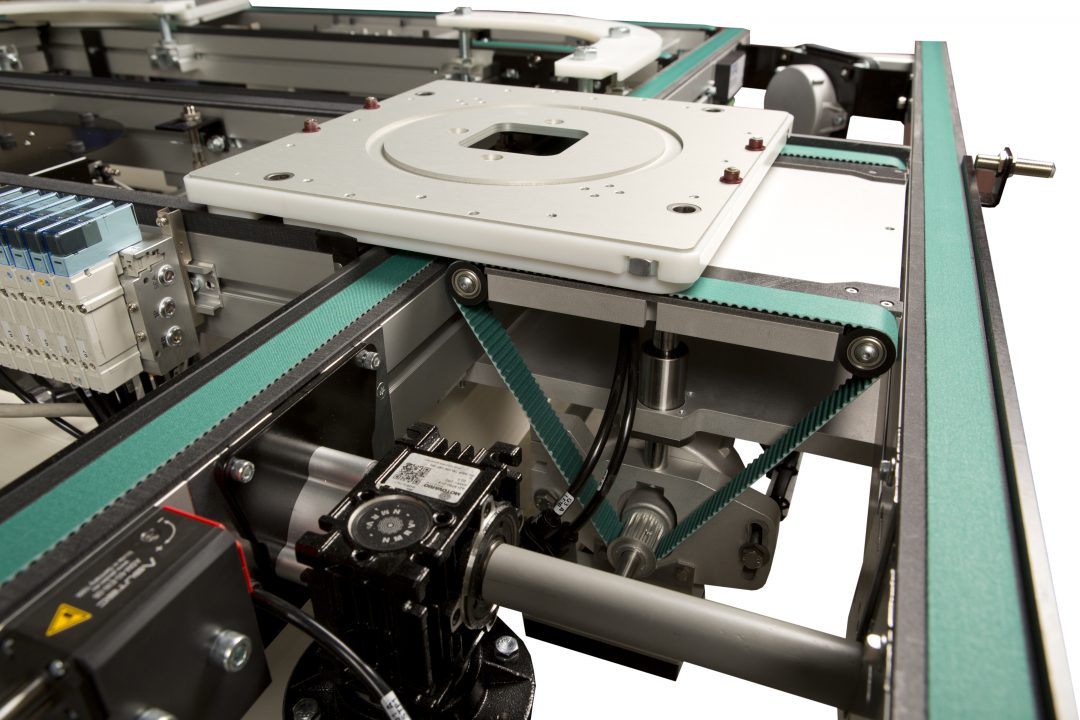

Pallet conveyors are often used because the product being transferred needs to be precisely located on the conveyor — typically for precision assembly or inspection operations. But if, during the transfer, some operations need to take place on different sides of the product, a lift and rotate module can facilitate this. These specialty conveyor modules lift the pallet slightly above the conveying media and rotate the pallet so that its orientation is changed but the original direction of transfer is maintained.

Lift and rotate modules change the orientation of the pallet (and the product) while maintaining the direction of transport.

Image credit: mk North America Inc.

Lift and rotate modules are also useful on conveyors with rectangular layouts. Here, a lift and rotate unit placed at the corner (where the conveyor makes a 90 degree turn), ensures the pallet maintains the proper orientation relative to the direction of conveying, even after it turns the corner.

Typical lift and rotate designs allow for 90 and 180 degree pallet rotations, but some manufacturers offer turntable-style modules that can rotate the pallet in smaller, predetermined increments (provided there is no interference with the conveyor or other structures). Lift and rotate units are generally driven by pneumatic cylinders, but servo- and stepper-driven units are available when precise, controlled rotation is required.

Lift and transfer conveyor modules

Some operations, such as curing, buffering, inspection, or processing, require that the product be taken “offline” to a station separate from the conveyor line or to a secondary conveyor near the primary line. In these cases, a lift and transfer module (sometimes referred to as a transverse conveyor) is used to move the pallet transversely. These conveyor modules lift the pallet a small distance above the conveyor and transfer it to a conveyor or workstation at right angles to the direction of the primary conveyor. Transfer units are commonly bi-directional, meaning they can transfer pallets both to and from the primary conveyor.

Lift and transfer modules (also referred to as transverse conveyors) move pallets to another conveyor or workstation 90 degrees from the primary conveyor.

Image credit: Dorner Mfg. Corp.

Most lift and transfer units use pneumatic lifts to raise and lower the pallet and belt or chain conveying media to transfer the product horizontally. Standard units maintain the orientation of the pallet (meaning its orientation relative to the direction of conveying will change by 90 degrees once it is transferred), although some manufacturers offer transfer units that can also rotate the pallet if necessary.

Vertical transfer units

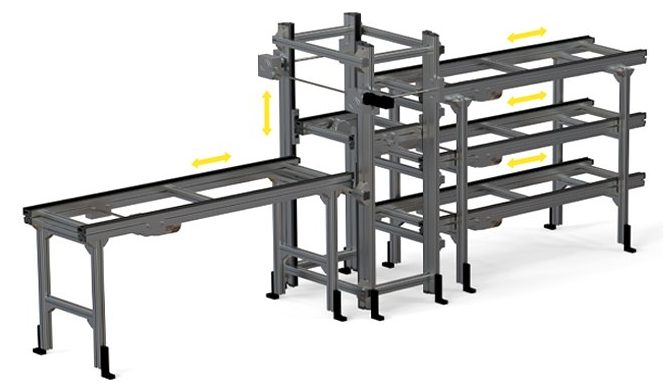

Pallet conveyors were traditionally used to transport products in two, horizontal dimensions. But a type of conveyor module referred to as a vertical transfer unit, or VTU, allows pallets to be transferred vertically to a different elevation — above or below the primary conveyor. Elevation changes allow “over-under” conveyor designs, where a second conveyor segment runs above (or below) the main conveyor. They also allow automatic transfer of pallets to a workstation located at a higher or lower elevation than the conveyor.

Vertical transfer units move products vertically to workstations or conveyors above (or below) the primary conveyor. They can also be used for storage or buffering.

Image credit: Glide-Line

Vertical transfer units can also be used for static operations that take place in the midst of product transport, such as temporary storage or buffering while a longer process – such as glue or adhesive curing – takes place. Vertical transfer units can be operated by pneumatic or electric lifts, with electric lifts allowing multiple, programmable stop positions and tight control over velocity.

Filed Under: Motion Control Tips