By Cat McClintock

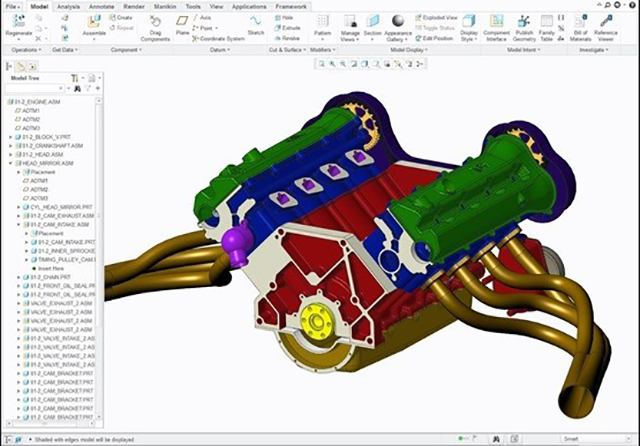

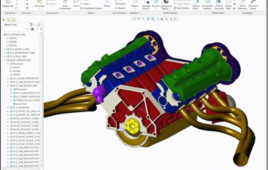

You might be familiar with Creo, PTC’s 3D CAD software. Engineers and designers use it to digitally create and update physical products. They can create geometry, organize parts into assemblies, form sweeping surfaces, and so on.

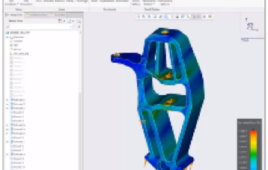

Creo also includes simulation tools so that engineers can test how these models might respond to various physical loads and forces. That helps in optimizing products before they ever get past the computer screen. Because waiting to find flaws later, when models reach prototyping, manufacturing, or consumers, is much more expensive.

But while simulation capabilities can be invaluable, they tax computer CPUs and cost time.

For every change to the model, you have to run a simulation study and wait for your computer to churn out the results. It might work pretty fast, but multiply that by all the different iterations you could go through, and the seconds and minutes adds up.

Think shaving a millimeter from a rib might save some weight without compromising strength? Try it, and then wait for your simulation. How about a half millimeter? Wait again. Nine-sixteenths? You get the picture.

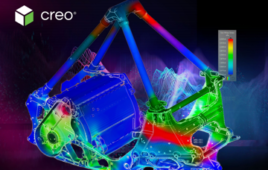

This is one way Creo Simulation Live is revolutionizing product design. Using technology first introduced by ANSYS, it makes simulation even more effective by eliminating that tweak-and-wait cycle.

What Is Creo Simulation Live?

Creo Simulation Live is a tool coming to Creo CAD software that lets engineers perform simulation in real time on a parametric model. “So every time you make a change in your model, you’ll see the consequences instantaneously in the modeling environment,” says Brian Thompson, SVP CAD Segment at PTC, in the video below.

No more waiting. And what about the load on your computer? Creo Simulation Live overcomes that by drawing memory from your system’s graphics card.

As a result, you just turn on Simulation Live with the click of a button and start working. “It’s as simple as that,” says Thompson.

More Simulations, Better Results

In case the benefits of instantaneous simulation aren’t immediately obvious, Thompson explains how it might lead to better products all around.

“We think this is so easy, so effortless, and instantaneous, customers will be more apt to use simulation in the design process,” says Thompson. “More simulations will result in higher quality parts that are much more likely to meet their requirements.”

So now design engineers can so quickly optimize a design. They no longer walk away when the model is “close enough.”

Creo Simulation Live Early Access Program: Try It on Your Own Models

Creo Simulation Live is unlike any design tool you’ve ever used before. Don’t believe it? Try on your own models absolutely free. You don’t even need to own Creo to get started. Choose from the following options:

- For current Creo users, download the most recent release Creo 5.0.3.0. Creo Simulation Live is fully integrated into your CAD software.

- For others, use the web version.

On February 27th, we’re bringing Creo Simulation Live to you on a live stream! You’ll hear the people behind the product, learn from customer examples and see a technical demonstration of Creo Simulation Live powered by ANSYS.

Using customer examples, we will show you how:

- Streamline product development and speed time-to-market

- Reduce product development cost (e.g., prototypes, rework, scrap, delays)

- Increase market share via increased quality, brand loyalty and competitive differentiation

- Reduce after-market service, warranty and repair cost

*This post originally appeared on the CAD Software Blog

Filed Under: Creo Simulation Live