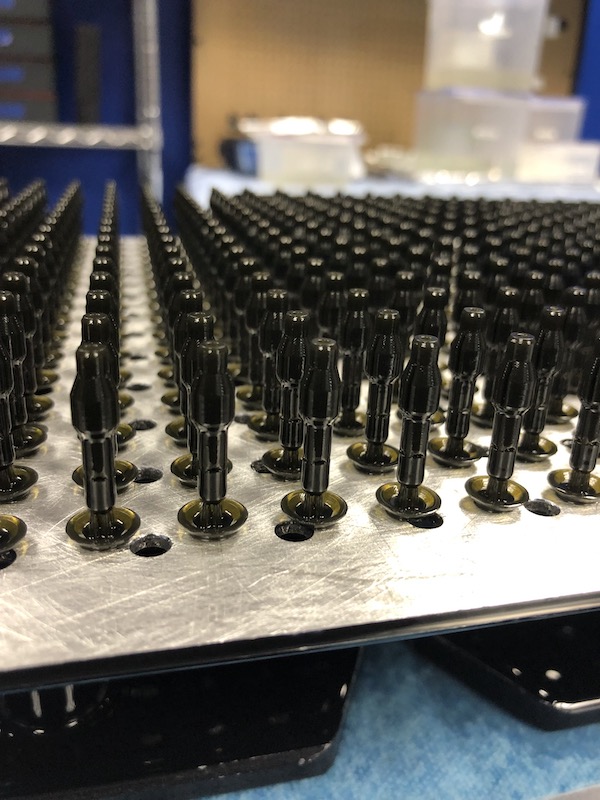

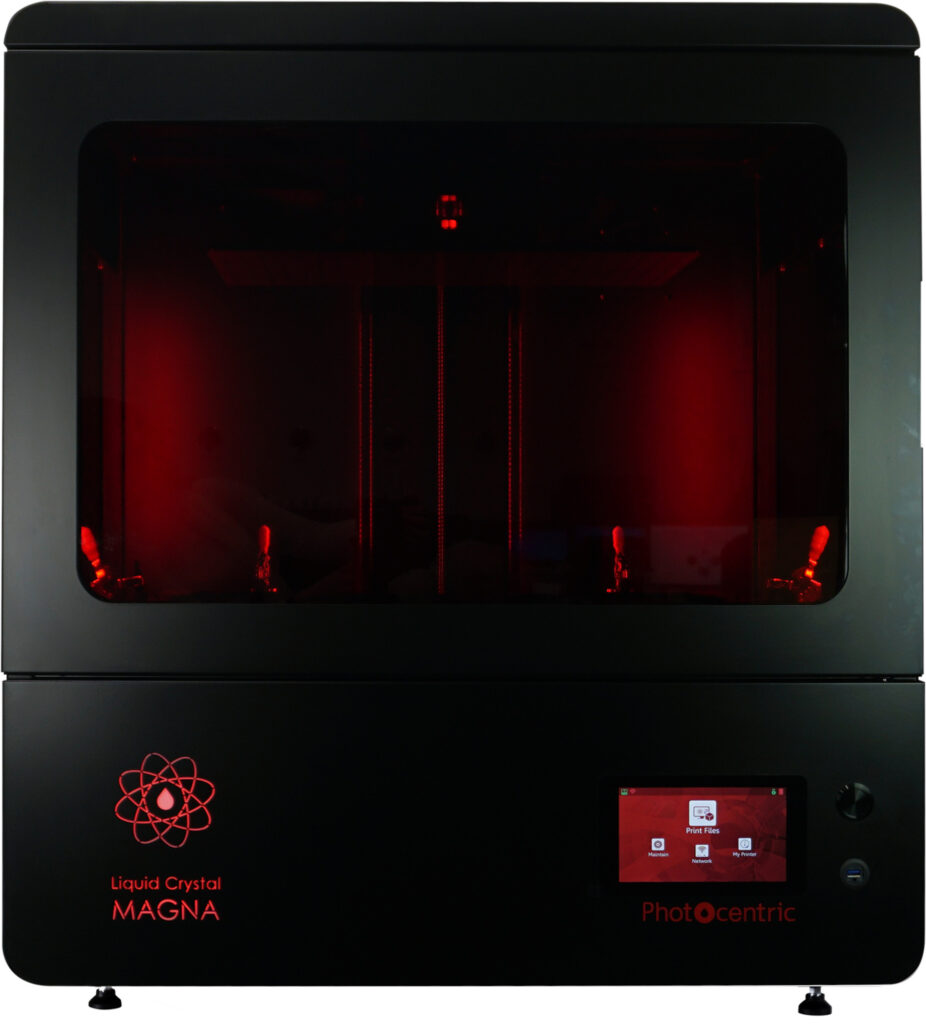

The 3D Printing Store (3DPS) used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser – which helps other entrepreneurs start their own auto glass repair businesses – to develop a part for its repair kit system. The proprietary technology helped Crack Eraser solve a challenging aspect of windshield repair, that of drilling into the top layer of laminated windshield glass at the point of impact where damage occurred. Using Photocentric LC Magna, 3DPS was able to manufacture over 1,000 drill collets, within acceptable tolerances, in just five hours of print time.

The precision 3D printed component, now known as the Drill Stop Collet, is used to hold the tiny glass drill used in windshield repair, and it has made this critical drilling process quick, reliable, and automatic. In the past, learning the correct technique required training, lots of practice, a high degree of fine motor skills and a lot of time to complete a repair successfully. The new part has simplified the job and enables Crack Eraser customers to make the perfect drill hole every time.

The 3D Printing store said that Photocentric technology was essential in both the rapid prototyping and production phases. They were able to print multiple drill collets to test the depth the drill bit would rest in each collet, and assess whether it was leading to a successful windshield repair. Once the design was finalized, production was fast and post processing was minimal.

Crack Eraser offers professional windshield repair kits, video training, expert support, and supplies. Owner Tim Evans has been in the business for 38 years, and he has continued to innovate and develop his own tools and processes to ensure the best outcome. Its kits have been designed to repair chips and long cracks in windshields up to 24 inches. Crack Eraser is the only company offering a proprietary 3D drill stop collet in every kit, marking a key point of difference from other competitors on the market.

“It’s very encouraging to see an innovative entrepreneur like Tim solving challenges by using additive manufacturing technology,” says Sally Tipping, sales director at Photocentric. “With LC Magna’s large build volume, it’s an excellent choice to produce end-use parts quickly and efficiently at scale, delivering speed, volume and cost savings to businesses. The intricate nature of this part means that precision tools are required, and in this case, LC Magna has been able to provide an agile and flexible solution for manufacture.”

Photocentric

photocentricgroup.com

Filed Under: Make Parts Fast