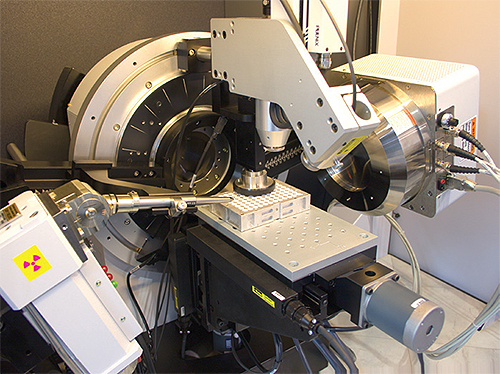

Few users approach the level of accuracy and repeatability requirements of Bruker AXS, a Madison, Wis., manufacturer of analytical instruments for the pharmaceutical industry and other markets. The company’s D8 Series of analytical diffractometers are typically found in research labs and R&D facilities at academic institutions as well as industrial locations. The systems address a wide range of analytical applications, including phase identification, phase quantification, small angle x-ray scattering, high-throughput screening (HTS), and microdiffraction. The brass worm gear assemblies position certain optics and shutters on the D8 Series.

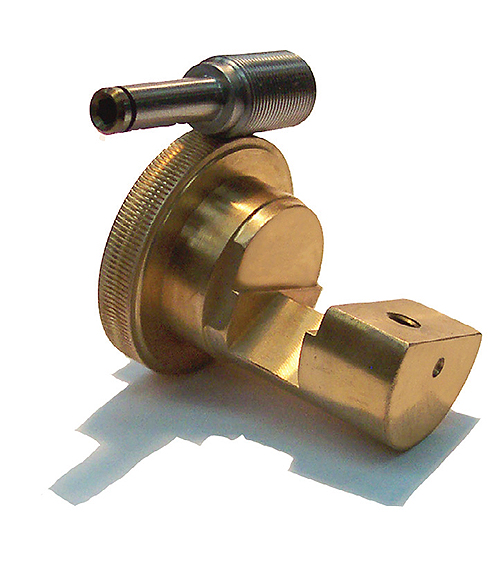

Gear set for D8 Series comprises a phosphor bronze gear and 17-4 stainless steel worm shaft. The gear is 164 diametral pitch.

“We had a gear set being manufactured by another supplier and then inspected by Forest City Gear. The results were not what we needed for our equipment, as the FCG testing quickly revealed,” Bruker said. “We worked closely with their engineering and production staff to achieve our required standards. Since that time, we’ve received better overall product quality at a lower cost. Plus, because of some innovations suggested by the FCG engineering team, we’ve achieved faster assembly times, better accuracy and longer service life in the field on our equipment.”

The D8’s flexibility requires an adaptable instrument to suit the task at hand, according to Schumacher. “Anyone whose day-to-day work involves pushing the limits of analytical research and science is dependent on instrumentation that can handle many changing requirements. The flexibility of our systems allows them to handle it all. The smallest and largest samples and sample amounts, inhomogeneous or oriented samples of complex shape geometry and possibly samples with heavier weight are very often the keys to being able to perform any analysis at all,” he said.

Some of the key components on the D8 series of diffractometers include an automated laser-video alignment system and the HI-STAR area detector. The combination of these two components enables simple precision alignment of sample features for instant analysis in snapshot or movie mode. The peak to background ratio of the data collected is close to the theoretical limits, owing to the unique sensitivity of the HI-STAR detector.

Close-up of Bruker’s x-ray beam generator, where precise 3-axis alignment of the beam is critical to valid evaluative procedures.

The FCG worm gear sets are used on these systems for the precise alignment and positioning of the incident beam. The proper alignment of a system starts with the incident beam, so the gear movements must be extremely accurate and highly repeatable.

Typically, the types of gears used on this equipment are designed in-house by Bruker’s mechanical engineering team.

“Early in our relationship, we met with the FCG engineers and quickly appreciated their expertise in gear design,” said Schumacher. “We frequently use that expertise to help us solve problems in our own designs. Every supplier to Bruker must prove their ability to supply us quality product, on time and at the agreed price.”

Forest City Gear Co., Inc.

www.forestcitygear.com

::Design World::

Filed Under: Medical-device manufacture, MECHANICAL POWER TRANSMISSION, Gears • gearheads • speed reducers, Motion control • motor controls

Tell Us What You Think!